Smart Vision Laser Cutter with Camera for Contour Cut

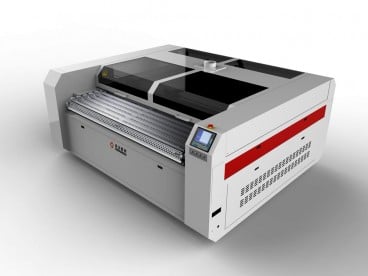

Model No.: QZDMJG-160100LD

Introduction:

This is a powerful camera laser machine for contour cutting. With one 18-million Pixel DSLR Canon Camera equipped, the machine can take photos of the digital printed or embroidered patterns, recognize the contour of patterns and then give cutting instruction for laser head to execute.

The two-laser-heads option makes this laser cutter machine implement high cutting efficiency as well.

QZDMJG-160100LD

Versatile Vision Laser Cutting System

QZDMJG-160100LD is a powerful camera laser machine for contour cutting.

With one 18-million Pixel DSLR Canon Camera equipped, the laser system can take photos of the digital printed or embroidered patterns, recognize the contour of patterns and then give cutting instruction for laser head to execute.

The two-laser-heads option makes this laser cutter machine implement high cutting efficiency as well.

Specifications

Laser Type

CO2 glass laser tube

Laser Power

80W / 130W / 150W

Cutting Area

1600mm×1000mm (63in×39.4in)

Scan Area

1500mm×900mm (59in×35.4in)

Working Table

Conveyor working table

Cooling System

Constant temperature water chiller

Power Supply

AC220V ± 5% 50/60Hz

Format Supported

AI, BMP, PLT, DXF, DST, etc.

Exhaust System

3 sets of 550W exhaust systems

Space Occupation

3184mm(L)×2850mm(W)×2412mm(H) / 125in(L)×112in(W)×95in(H)

Highlights of the Vision Camera Laser Cutter

High resolution camera positioning

- To capture pictures clearer

- Camera shooting the whole format, avoiding splicing graphics

- Supporting higher pixel camera optional

The fifth-generation vision recognition software

- High precision edge-seeking processing mode

- Multi-template processing mode

- Graphics can be partial or total modification

Automatic laser cutting system

- With automatic feeder

- Automated continuous processing

- A variety of processing format optional

User-friendly operation system

- Real-time observation machining path

- Quick alignment processing the products that are unable to identify manually

- Using Internet technology to set up centralized control center, to achieve unmanned laser processing plant

Advantages of the Smart Vision System

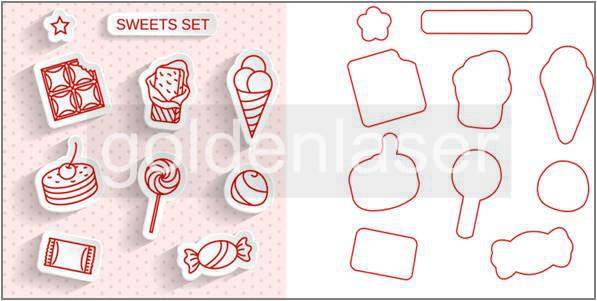

No limitation of graphic size or templates. One time image acquisition by camera, any complex graphics can be precisely cut. Through high precision camera one time imaging for the full format material, this system can directly extract patterns contour and automatic cut. Or using graphical feature points to achieve aligning and cutting according to the original design. It supports real-time modification in the processing, no limitations on a variety of graphics. It is the best automated solution for digital printing, personalized labels, embroidery and other positioning cutting process.

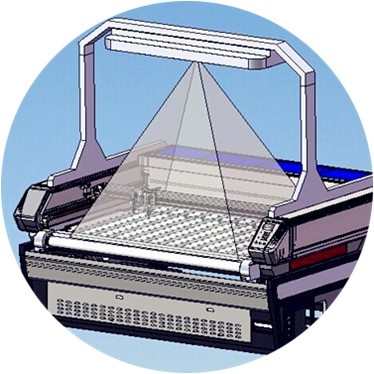

Camera

• CANON 18-megapixel high-resolution SLR camera

• 24 million pixel camera for option

• The recognition format can reach 1500 × 900mm. Compared with CCD system, graphics do not need to be spliced, and the recognition accuracy is higher.

• The camera is installed on the top of laser machine. Compared with CCD camera, the recognition format is larger and the laser head processing efficiency is higher.

Software

• It can directly catch outline of the pattern and edge-following cutting

• Compatible with the fifth generation CCD vision template cutting function

• The outlines of the object could display above its corresponding image after matching, convenient for judging the precision directly

• Continuously recognizing, feeding and cutting

• High working efficiency: All different patterns only one time catching.

Multiple recognition modes

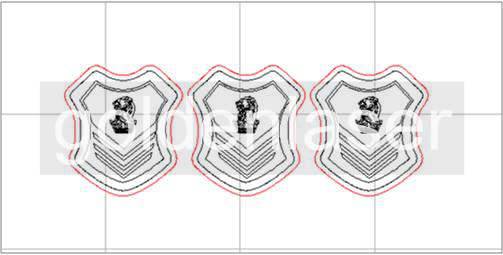

Outline catching and recognition mode

Suitable for clear outline design

Working process: (As shown in the figure above)

1、Camera shooting the pattern design

2、Recognition software extracts the outline of the graphics to be processed (the red line in the figure above)

3、The laser head cuts along the red outline

Advantage:

When the material is distorting or stretched, the contour of the figure is always recognized

Multi-template recognizing mode

Suitable for complicated patterns or unclear outline

Working process: (As shown in the figure above)

1、Take photo of the whole area designs

2、Input drawings (As shown in the figure above)

3、Laser head cutting according to the template

Advantages:

Suits for any designs

Application

This Vision Camera Laser Cutter is the best fit for digital printed fabrics, labels, garment and shoes accessories industry, especially suitable for small and medium batch production and customized processing. The laser cutting solution can realize digital, intelligent and automated efficient production.

Watch How the Laser Cutting System Works

We offer only the best laser machines that cater to your specific requirements, but don't just take our word for it. We want you to see the machine in action! Watch this short feature clip of this machine.

If you feel that this may be the perfect machine for your needs, our team will be more than happy to schedule an actual demo for you.

Technical Parameters of the Smart Vision Laser Cutter

| Laser type |

Sealed CO2 glass laser tube |

|

| Laser power |

130W / 150W (Optional) |

|

| Working area |

1.6m×1m |

1.8m×1m |

| Scan area |

1.5m×0.9m |

1.7m×0.9m |

| Camera pixels |

18 million pixels / 24 million pixels (Optional) |

|

| Working table |

Conveyor working table |

|

| Processing accuracy |

±0.1mm |

|

| Moving system |

Stepping motor / Servo motor (Optional) |

|

| Cooling system |

Constant temperature water chiller |

|

| Exhaust System |

Exhaust blower 550W / 1.1KW (Optional) |

|

| Power supply |

AC220V ± 5% 50/60Hz |

|

| Software |

Goldenlaser Smart Vision Cutting System |

|

| Graphics formats |

PLT, DXF, AI, BMP, DST, etc. |

|

| Dimensions |

2.48×2.08×2.5 (m) |

2.65×2.12×2.5 (m) |

| Net Weight |

730Kg |

800Kg |

Goldenlaser’s Full Range of Vision Laser Cutting Systems

Ⅰ Smart Vision (Dual Head) Laser Cutting Series

| Model No. | Working area |

| QZDMJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| QZDMJG-180100LD | 1800mm×1000mm (70.8”×39.3”) |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

Ⅱ High Speed Scan On-the-Fly Cutting Series

| Model No. | Working area |

| CJGV-160130LD | 1600mm×1300mm (63”×51”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

Ⅲ High Precision Cutting by Registration Marks

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

Ⅳ Ultra-Large Format Laser Cutting Series

| Model No. | Working area |

| ZDJMCJG-320400LD | 3200mm×4000mm (126”×157.4”) |

Ⅴ CCD Camera Laser Cutting Series

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

Smart vision laser system can be applied to the following industries

› Swimwear, cycling apparel, sportswear, T Shirt, Polo shirt

› Warp fly knitting vamp

› Advertising flags, banners

› Printed label, printed number and logo

› Clothing embroidery label, applique

The laser solution for label, printed fabrics and garment accessories industry, especially for small and medium-volume production and customization of manufacturers, achieves digital intelligent automation efficient production.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp…)?