Would you like to get more options and availability of goldenlaser machines and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

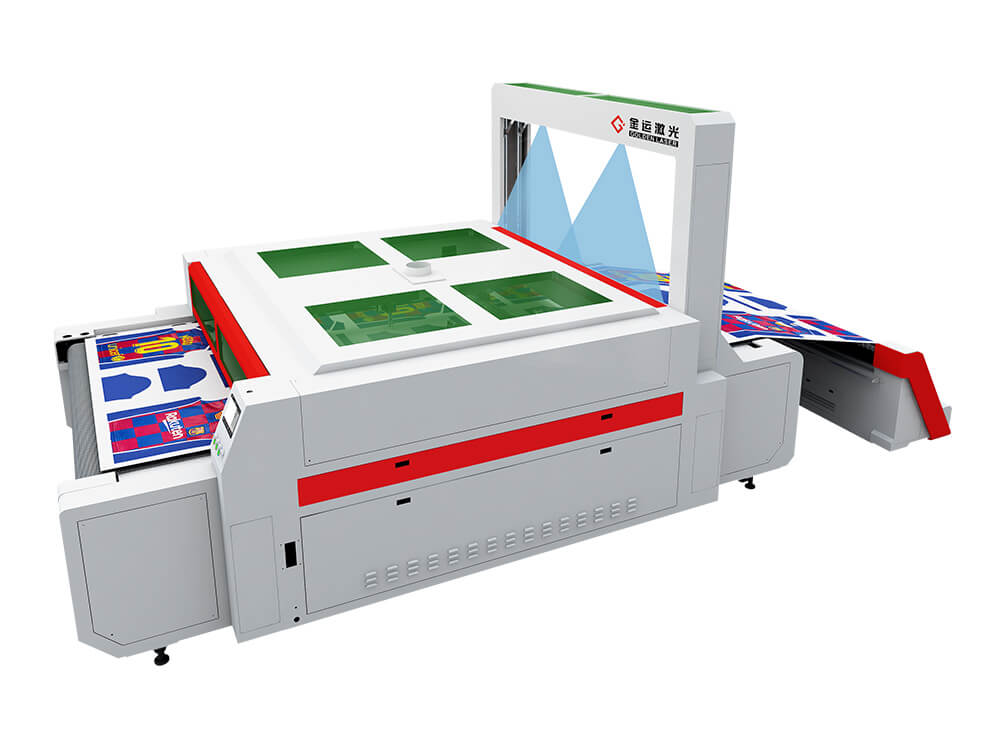

Digital Printing Fabric Laser Cutter for Sublimation Clothes

Model No.: CJGV160130LD

Introduction:

Vision laser cutting machine automates the process of cutting digital printed pieces of fabric or textile both quickly and accurately, two cameras recognition automatically compensates for any distortions and stretches that occur in unstable or stretchy textiles that are used for sportswear, sublimated suits, cycling wear, polo shirt, fashion printing apparel and banner flags, etc.

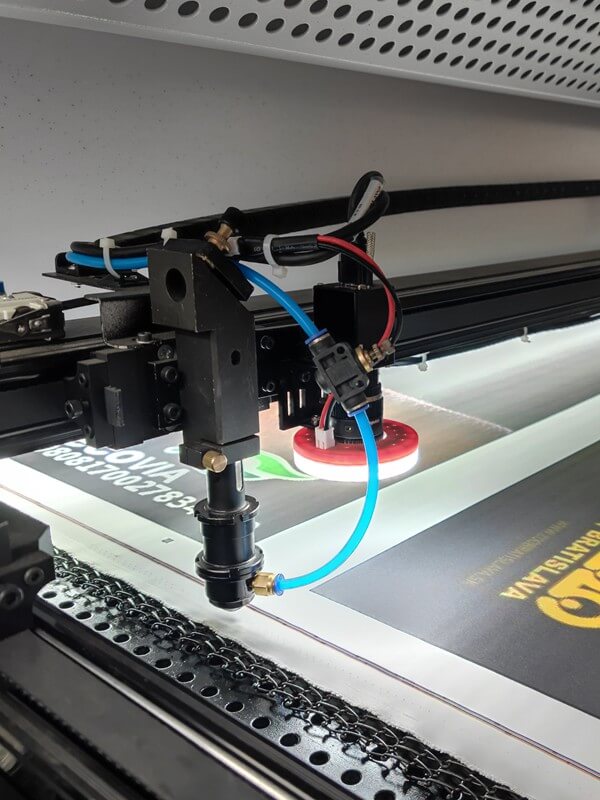

How Vision Laser Cutter Works?

Advantages

VisionLASER Two Detect Mode

Advantages of Contour Detection

1) No required the original graphics files

2) Directly detect a roll of printed fabric

3) Automatic without manual intervention

4) Fast - 5 seconds for an entire cutting format recognition

Advantages of Printing Marks Detection

1) High precision

2) No limit on the gap between the patterns

3) No limit on color difference with background

4) Compensate the materials distortion

Vision Laser Cutter for Sublimation Apparel Demo

Discover more photos of the machine in action

Looking for further information?

Technical Parameter of the Vision Laser Cutter CJGV160130LD

| Working area | 1600mm x 1200mm (63” x 47.2”) |

| Camera scanning area | 1600mm x 800mm (63” x 31.4”) |

| Collection area | 1600mm x 500mm (63” x19.6”) |

| Working table | Conveyor working table |

| Vision system | Industrial cameras |

| Laser power | 150W |

| Laser tube | CO2 glass laser tube / CO2 RF metal laser tube |

| Motors | Servo motors |

| Cutting speed | 0-800 mm/s |

| Cooling system | Constant temperature water chiller |

| Exhaust system | 1.1KW Exhaust fan x 2, 550W Exhaust fan x1 |

| Power supply | 220V / 50Hz or 60Hz / Single phase |

| Electrical standard | CE / FDA / CSA |

| Power consumption | 9KW |

| Software | GoldenLaser Scanning Software Package |

| Space occupation | L 4316mm x W 3239mm x H 2046mm (14′ x 10.6′ x 6.7’) |

| Other options | Auto feeder, red dot, CCD camera for registration |

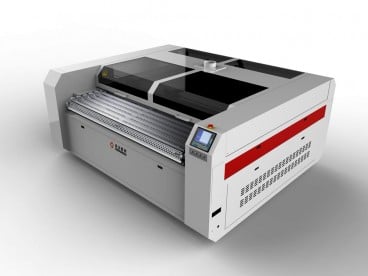

GOLDENLASER Full Range of Vision Laser Cutting Systems

Ⅰ High Speed Scan On-the-Fly Cutting Series

| Model No. | Working area |

| CJGV-160130LD | 1600mm×1200mm (63”×47.2”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

Ⅱ High Precision Cutting by Registration Marks

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

Ⅲ Ultra-Large Format Laser Cutting Series

| Model No. | Working area |

| ZDJMCJG-320400LD | 3200mm×4000mm (126”×157.4”) |

Ⅳ Smart Vision (Dual Head) Laser Cutting Series

| Model No. | Working area |

| QZDMJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

Ⅴ CCD Camera Laser Cutting Series

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

Laser Cutting Sublimated Fabric Samples

Laser cutting sublimated apparel fabric with clean and sealed edges

Laser cutting hockey jerseys

Application

→ Sportswear Jerseys (basketball jersey, football jersey, baseball jersey, ice hockey jersey)

→ Cycling apparel

→ Active wear, leggings, yoga wear, dance wear

→ Swimwear, bikinis

Please contact goldenlaser for further information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (laser marking) or laser perforating?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product (application industry)?