professional factory for Automatic Bundle Loader Fiber Laser Pipe Cutting Machine to Bhutan Manufacturer

professional factory for Automatic Bundle Loader Fiber Laser Pipe Cutting Machine to Bhutan Manufacturer Detail:

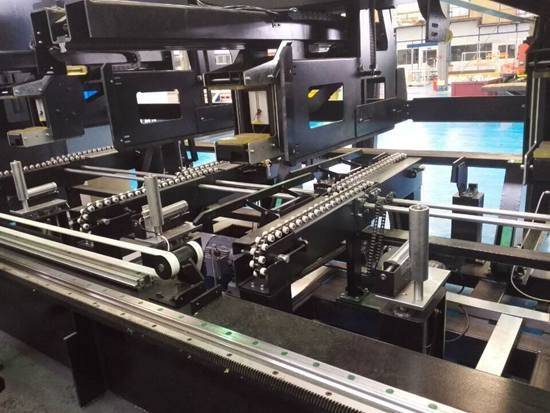

Automatic Bundle Loader Fiber Laser Pipe Cutting Machine

Advanced chuck clamping system

◇ Chuck center self-adjustment, automatically adjust the size of the clamping force according to the profile specifications, to ensure non-destructive thin tube clamping.

◇ Two linked right move claws, compatible with a variety of pipe without adjusting jaws.

Corner fast cutting system

◇ Corner fast response, greatly improving cutting efficiency.

Lift adjustable support system

◇ Simple change pipe type, installed to save time, reduce pipe swing.

◇ Auxiliary loading and unloading system perfect switch.

Automatic collecting

◇ Automatic elevating support, receive tube and scrap into the basket.

◇ Visual scale support can adjust support diameter quickly according to pipe diameter.

◇ Visual scale adjustable support lifting device saves feeding time, ensures concentricity, prevents pipe swing.

Automatic Bundle Loader

◆ Round pipe, rectangular pipe and other pipes can be fully automated loading. Other shapes pipe can be semi-automatic feeding manually.

General Details

General Details

◆ Maximum loading bundle 800mm×800mm

◆ Maximum loading bundle weight 2500Kg

◆ The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers.

◆ The tape support frame for easy disassembly.

◆ Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport.

◆ The pneumatic system components used AirTAC or other more high-end brand. PLC control, sensors selected Omron, Schneider and other well-known brand. Ensure the stability of the system and export standard.

Golden Laser - Fiber Laser Tube Cutting Machine

Laser Cutting Tube in Batch Production