Would you like to get more options and availability of goldenlaser systems and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

Laser Cutting of Velcro Material

Laser Cutting Solutions for Velcro Material

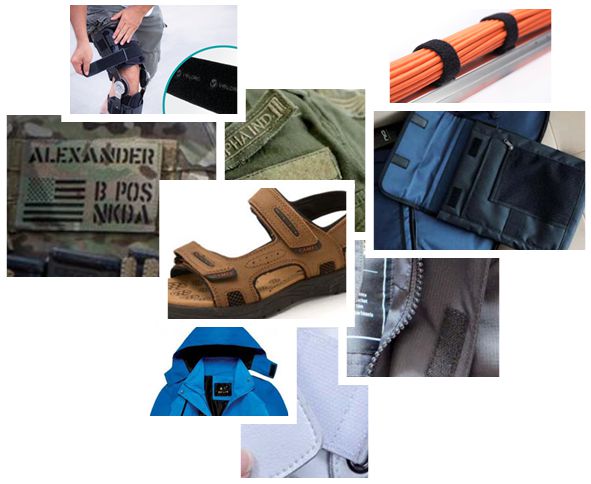

As an alternative to fixing objects, Velcro® is very popular in the apparel, footwear and automotive industries (as well as others) for its lightweight, washable and durable properties, thanks to its ability to provide a firm grip under tension, but easily separated when necessary.

The hooks of Velcro® and other hook and loop fasteners are usually made from nylon or polyester. The special structure of Velcro materials makes it difficult to meet certain requirements with conventional machining methods such as knife and punching processes. CO2 laser cutting machines from goldenlaser has proven to be ideally suited to the cutting of Velcro materials, producing a smooth and exact cutting with slightly melted edges.

The benefits of cutting Velcro using lasers:

Fused cut edges

Complex curve graphics

Cutting and perforation in one operation

Typical application segments of Velcro:

• Footwear & Apparel

• Bags & Backpacks

• Sports Equipment

• Industrial Sector

• Automotive Sector

• Military & Tactical Gear

• Medical & Personal Care

• Packaging Industry

• Mechanical Engineering

Material information of Velcro:

Velcro is the generic brand name for a type of hook-and-loop fasteners trademarked by the Velcro Group of companies. The fastener consists of two components: a lineal fabric strip with tiny hooks that could 'fitted' with another fabric strip with smaller loops, attaching temporarily, until pulled apart. There are various types of Velcro, differing in size, shape and application. Industrial Velcro, for instance, consists of woven steel wire that provides high tensile bonding in high-temperature applications. Consumer Velcro typically comes in two materials: polyester and nylon.

The use of Velcro is diverse and has a high degree of freedom. It is used in a wide range of applications in the outdoor, clothing, industrial, automotive and spacecraft sectors. The strong pulling power of Velcro is effective even in harsh environments.

In many cases customers want to cut various shapes out of velcro material. Laser cutting processes can help your product meet exacting specifications. Laser cutting machine, in conjunction with CAD design and programming, allows you to completely customize your material for any production application. Fully automatic processing from rolls is possible thanks to conveyor system and auto-feeder.

Material information of Velcro:

- Nylon

- Polyester

We recommend the following laser machines for the cutting of Velcro material:

Model No.: ZDJG-3020LD

Working Area 300mm×200mm

Laser Power: 65W~150W

Model No.: MJG-160100LD

Working Area 1600mm×1000mm

Laser Power: 65W~150W