- English

- Chinese

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Laser Cutting of Insulation Materials and Protective Materials

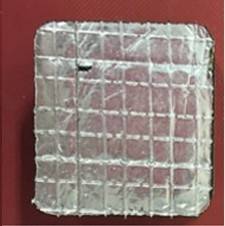

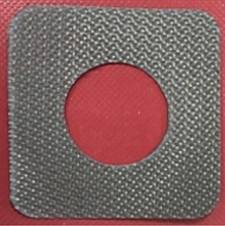

Laser cutting is replacing the traditional knife cutting gradually. Unlike most of the non-metal materials, insulation materials require optimal functionality and durability. In order to meet exceptional thermal efficiency, high strength, low weight and low shrinkage at excessive temperatures, the composition of thermal insulation material is very complex, or more specifically to describe – difficult to cut. Our research and technology team invented special laser cutting machine with adequate power for such features.

Utilizing laser cutting machine developed by goldenlaser, it is possible to efficiently manufacture products from almost all of the technical textiles and composite materials in insulation and protective industry, no matter how complex the shape, or how small or large the product. When cutting, the laser cutting process seals all the edges of the synthetic materials that are prone to become worn and unravel. This process, in turn, prevents future fraying, ensuring the reliability of a product that will last.

Main Insulation Materials for Laser Cutting

Fiberglass, Mineral Wool, Cellulose, Natural Fibers, Polystyrene, Polyisocyanurate, Polyurethane, Vermiculite and Perlite, Urea-formaldehyde Foam, Cementitious Foam, Phenolic Foam, Insulation Facings, etc.

The Advantages of Laser Cutting

Machine Recommendation

We recommend the following laser machine for the cutting of insulation materials and protective materials

• Gear and Rack Driven

• High speed, high precision

• Vacuum conveyor

• Various working areas optional

Laser type:

CO₂ glass Laser / CO₂ RF Laser

Laser power:

150 watts ~ 800 watts

Working area:

Length 2000mm~13000mm, Width 1600mm~3200mm

Application:

Technical textiles, industrial fabrics, etc.