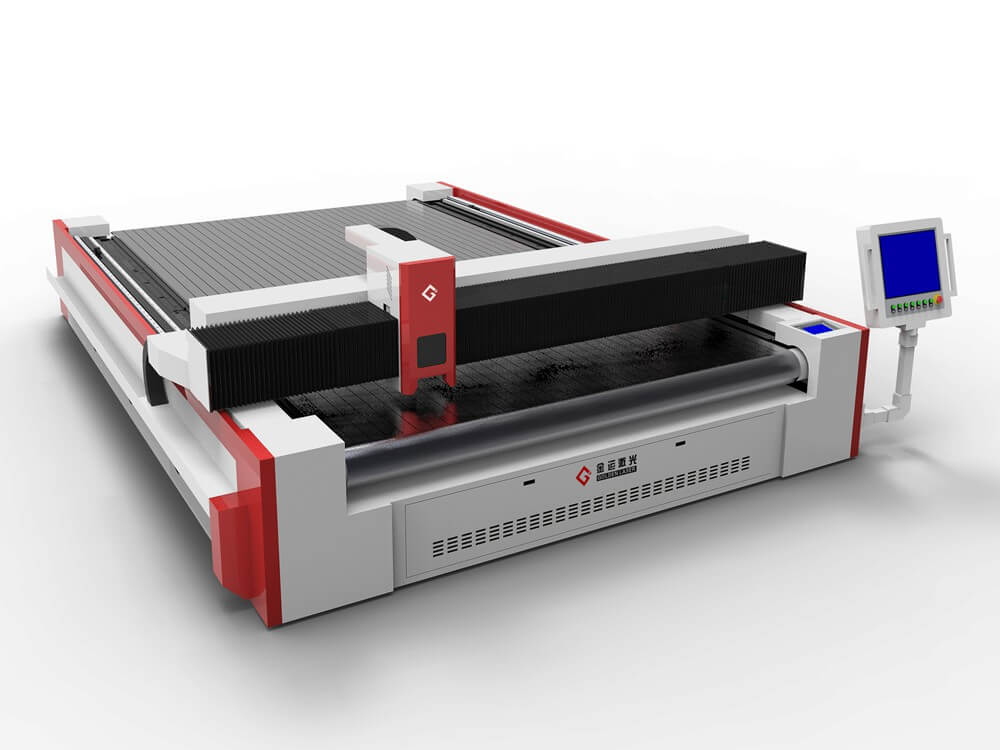

High Speed Industrial Textile Fabric Laser Cutting Machine

Model No.: JMCCJG / JYCCJG Series

Introduction:

- This series CO2 flatbed laser cutting machine is designed for wide textile rolls and soft materials automatically and continuously cutting.

- Driven by gear and rack with servo motor, the laser cutter offers the highest cutting speed and acceleration.

- The software package and extra options come with the laser cutting system is provided to achieve digital and intelligent processing.

The CO2 flatbed fabric laser cutter is designed for wide textile rolls and soft materials automatically and continuously cutting. Driven by gear and rack with servo motor control, the laser cutting machine offers high precision and cut quality at the highest cutting speed and acceleration. The laser cutter machine is available with a laser power from 150 watt to 800 watt. The large format cutting table can be applied to most of the typical fabric rolls.

With the option of the auto-feeder, roll materials are fed to the cutting table directly and cut continuously. The machine is with vacuum suction underneath the conveyor working table, which ensures the materials to be flat on the table. Different vision systems can be equipped with this laser machine for diversified application such as dye sublimation printed textile cutting. And mark pen or ink-jet print head option is available to make marks for sewing or other purpose.

Machine Features

Features of the High performance flatbed CO2 laser cutting machine

• This laser cutting machine delivers fast and extremely accurate processing thanks to its high-quality components. Very dependable and maintenance free.

High precision grade gear and rack driving system. With high-powered CO2 laser tube, cutting speed up to 1,200mm/s, acceleration up to 8,000mm/s2, and can maintain long-term stability.

Japanese Yaskawa servo motor

- Ensure maximum precision, reliability, and performance.

• This laser machine comes with conveyor system. The machine feeds the material automatically in a continuous cycle in synchronism with the conveyor bed eliminating downtime completely to achieve the maximum productivity possible.

In addition, the vacuum conveyor worktable has the function of negative pressure adsorption to ensure the flatness of the fabric during laser cutting.

• Automatic feeder with deviation correction function (optional) to ensure accurate feeding.

• The unique manual and automatic interactive nesting software function can improve the fabric utilization to the extreme.

• Along with the exhaust system, the laser head and the exhaust system synchronize; good exhaust effect, to ensure that dust dose not pollute the materials.

• It is possible to complete entire format cutting of the extra-long layout with a single layout length that exceeds the cut format.

• The laser cutting system is modular in design as per customers' processing demands.

Quick Specifications

| Laser type | CO2 RF metal laser |

| Laser power | 150W 300W 600W 800W |

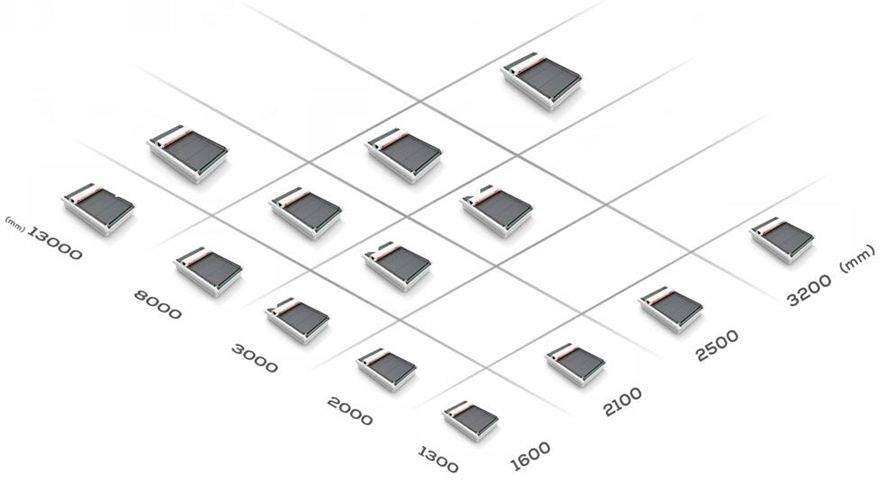

| Working area | 2000mm~8000mm(L) ×1300mm~3200mm(W) |

| Working table | Vacuum conveyor working table |

| Motion system | Rack and pinion transmission, Servo motor drive |

| Cutting speed | 0~1,200mm/s |

| Acceleration | 8,000mm/s2 |

| Laser type | CO2 DC glass laser |

| Laser power | 150W 300W |

| Working area | 2000mm~8000mm(L) ×1300mm~3200mm(W) |

| Working table | Vacuum conveyor working table |

| Motion system | Rack and pinion transmission, Servo motor drive |

| Cutting speed | 0~600mm/s |

| Acceleration | 6,000mm/s2 |

Laser Cut Processing Workflow

How Co2 laser cutting machine for textile processing works?

Highlights of the Flatbed CO2 Laser Cutter

Optional extras simplify the processing production and increase the possibilities

Safety Protective Cover

Making the processing safer and reducing fume and dust that may be generated during processing.

It is available with Full Enclosed option to meet class 1 laser product safety protection.

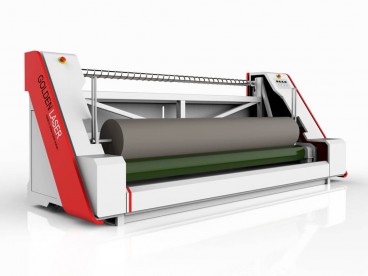

Auto Feeder

It is a feeding unit which runs synchronous with the laser cutter. the feeder will transfer the roll materials to the cutting table after you put the rolls on the feeder. You can set the different feeding speeds according to the main machine speed. The feeder has the sensor to ensure accurate positioning of the material. The feeder can be equipped with different shaft diameters for different rolls. The different pneumatic roller will be used for the textiles with different tension, thickness... This unit helps you to realize a completely automated cutting process.

Vacuum Suction

The vacuum table is under the cutting table, there is a series of holes in the surface of the table pull the material down onto the surface. The vacuum table allows full access to the surface, there is nothing to get in the way of the laser beam while it is cutting. With the strong exhaust fans together, it also helps to prevent the smoke and dust when cutting.

Vision System

The vision system is an important option when you want to cut the contours. No matter for printing contour or embroidery contour, you will need this device to read the contour or special data for positioning and cutting. Contour scanning and marks scanning are suitable for different application. We offer different vision options for different applications.

Marking Modules

1. Mark pen

For most of the laser cutting pieces, especially for textiles, it has to be sewn after cutting. You can use the mark pen to make the marks on the cutting piece to help the workers for easy sewing. You can also use the mark pen to make some special marks on the cutting piece such as the serial number of the product, the size of the product, the manufacture date of the product and etc...You can choose different color mark pens according to the color of your materials.

2. Ink-jet printing

Comparing with the “mark pen” the ink-jet printing technology is a non-touch process, so it can be used for many more different types of materials. And there are different inks for an option such as volatile ink and non-volatile ink, so you can use it in different industries.

Red Dot Pointer

- Laser Beam Tracing System

The red dot pointer helps as a reference to check where the laser beam will land on to your material by tracing a simulation of your design without activating the laser. As well as your starting point.

Dual Head

Basic two laser heads

The two laser heads are mounted on the same gantry, which allow for two same patterns to be cut simultaneously.

Independent dual heads

The independent dual heads can cut different designs at the same time. It increases the cutting efficiency and production flexibility at the largest degree.

GALVO Head

Galvo laser uses high-speed, motor-driven mirrors to steer the laser beam through a lens. Depending on the position within the laser marking field, the beam impacts the material at a greater or lesser angle of inclination. The marking field size is defined by the deflection angle and the focal length of the optics. Since there are no movable parts (with the exception of the mirrors) the laser beam can be guided over the work-piece at extremely high speeds with high precision and reliability, making them ideal when short cycle times and high-quality markings are required.

Automatic Sorting System

Increased level of automation during the unloading and sorting process also accelerates your subsequent manufacturing processes.

The benefits of textiles cutting with laser systems by goldenlaser

Clean edges - Lint-free cuts

The laser automatic seals the cutting edges and thus, prevents fraying. Compared to mechanical cutting, laser cutting saves many working steps in further processing.

Continuous cutting from roll

Laser cutting textiles and fabrics directly from the roll thanks to the conveyor system and automatic feeder. Capable of ultra-long format processing.

Laser cutting of extremely fine details

Laser is ideally suitable for cutting absolutely incredibly complicated internal shapes and designs, even cut extremely small holes (laser perforation).

Technical Parameters of the Laser Cutter Machine

| Models |

JMCCJG SERIES |

JYCCJG SERIES |

| Laser type |

CO2 RF metal laser |

CO2 DC glass laser |

| Laser power |

150W 300W 600W 800W |

150W 300W |

| Working area |

2000mm~8000mm(L) ×1300mm~3200mm(W) |

|

| Working table |

Vacuum conveyor working table |

|

| Motion system |

Rack and pinion transmission, Servo motor drive |

|

| Cutting speed |

0~1,200mm/s |

0~600mm/s |

| Acceleration |

8,000mm/s2 |

6,000mm/s2 |

| Lubrication system |

Automatic lubrication system |

|

| Fume extraction system |

Specialized connection pipe with N centrifugal blowers |

|

| Power supply |

AC380V±5% 50/60Hz 3Phase / AC220V±5% 50/60Hz |

|

| Graphic Format Supported |

PLT, DXF, AI, DST, BMP |

|

※ Table size, laser power and configurations can be customized as per requirement.

GOLDENLASER – HIGH SPEED HIGH PRECISION CO2 LASER CUTTER

Working areas: 1600mm×2000mm (63″×79″), 1600mm×3000mm (63″×118″), 2300mm×2300mm (90.5″×90.5″), 2500mm×3000mm (98.4″×118″), 3000mm×3000mm (118″×118″), 3500mm×4000mm (137.7″×157.4″), etc.

***The bed sizes can be customized according to different applications.***

Applicable Materials

Polyester, nylon, nonwoven and woven fabrics, synthetic fibers, PES, polypropylene (PP), polyamide (PA), glass fiber (or glass fibre, fiberglass, fibreglass), Kevlar, aramid, Lycra, polyester PET, PTFE, paper, foam, cotton, plastic, viscose, felts, knitted fabrics, 3D spacer fabrics, carbon fibers, cordura fabrics, UHMWPE, sail cloth, microfiber, spandex fabric, etc.

Applications

1. Clothing Textiles: fabrics and technical textiles for clothing applications.

2. Home Textiles: carpets, mattress, sofas, armchairs, curtains, cushion materials, pillows, floor and wall coverings, textile wallpaper, etc.

3. Industrial Textiles: filtration, air dispersion ducts, etc.

4. Textiles used in automotive and aerospace: aircraft carpets, car mats, seat covers, seat belts, airbags, etc.

5. Outdoors and Sports textiles: sports equipment, flying and sailing sports, canvas covers, marquee tents, parachutes, paragliding, kitesurf, etc.

6. Protective textiles: insulation materials, bulletproof vests, etc.

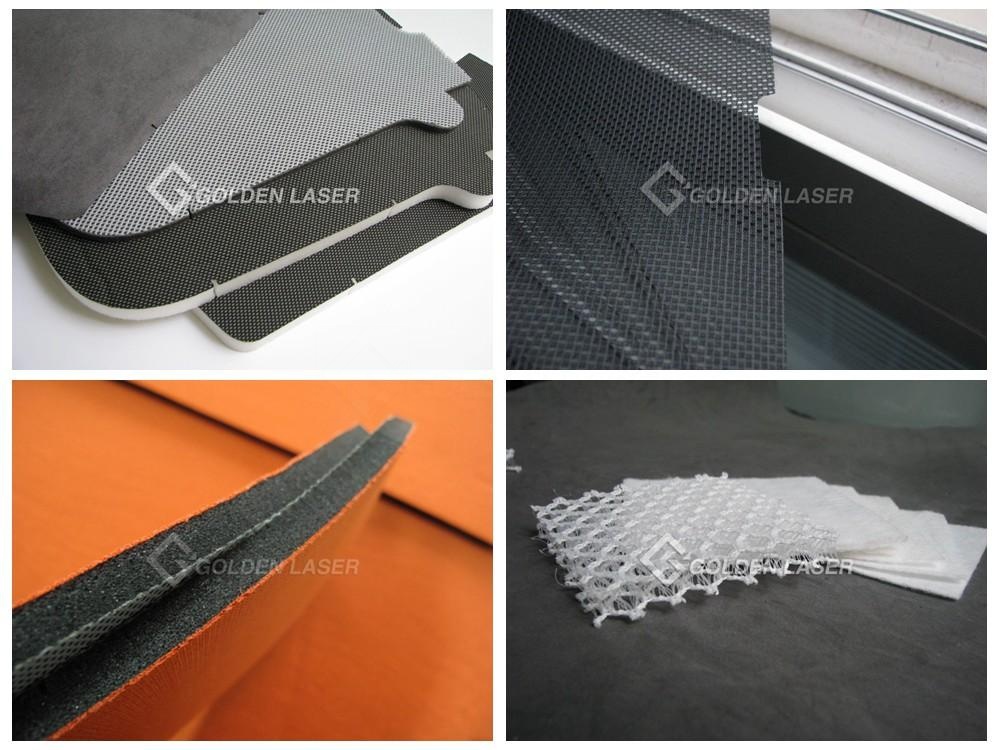

Textiles Laser Cutting Samples

Please contact Golden Laser for further information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (laser marking) or laser perforating?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product (application industry)?