Would you like to get more options and availability of laser systems and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

- English

- Chinese

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Laser Cutting of Kevlar and Aramid

Applicable Laser Processing for Kevlar (Aramid) - Laser Cutting

Kevlar and aramid are difficult to cut using conventional machining methods because of their thermal and mechanical properties. Cutting of Kevlar and aramid with conventional methods results in poor end-product quality and excessive specific energy requirement for machining. However, laser machining has considerable advantages over the conventional methods due to precision and rapid processing.

As a modern cutting tool, laser cutting machine offers the advantages of a high-quality end product, operational precision and a high degree of flexibility, resulting in very well accepted in the textile and industrial sectors. Cutting through Kevlar with CO2 laser cutter is very doable. Laser cutting is contactless and, unlike knives or blades, the laser beam is always sharp and does not dull, thus ensuring consistent cut quality. The heat generated by the laser during the cutting of Kevlar seals the edges and eliminates fraying.

Benefits from Laser cutting of Kevlar (Aramid)

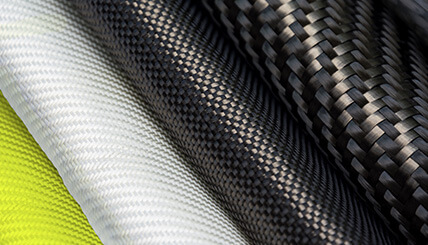

Aramid, Kevlar material information and related laser cutting technology

Aramid, short for "aromatic polyamide", is a high-performance man-made synthetic fiber. Aramid has a number of beneficial mechanical properties that make it such an important material in many different fields. It is usually used as fibre reinforcement for polymer matrix composites. Kevlar is a type of aramid fiber. It is woven into textile materials and is extremely strong and lightweight, with resistance toward corrosion and heat. It is used in vast applications such as aerospace engineering (such as the body of the aircraft), body armor, bulletproof vests, car brakes, and boats. It is usually made into composites. Kevlar can also be combined with other fibers to produce hybrid composites.

Due to their high strength and toughness as well as the fibres tend to fuzz, aramid and Kevlar are difficult to drill and cut, requiring special device to cut the material. Laser cutting is a powerful and effective processing method for many composites. Laser cutting machine is capable of cutting various forms of composite materials, including aramid and Kevlar, making it possible to provide economic solutions for rapid turnover of high-quality products.