Would you like to get more options and availability of goldenlaser machines and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

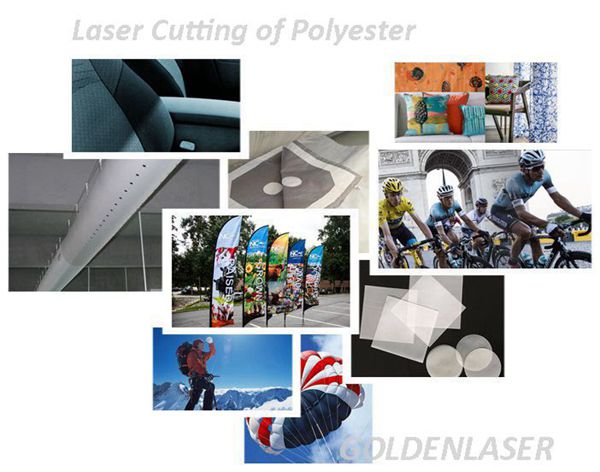

Laser Cutting of Polyester Fabric

Applicable laser processes for polyester fabric

1. Laser Cutting

Polyester fabrics respond very well to the laser cutting process with clean and neat cut edges, preventing fraying after cutting. The high temperature of the laser beam melts the fibres and seals the edges of the laser cut textile.

2. Laser Engraving

Laser engraving of fabric is to remove (engrave) the material to a certain depth by controlling the power of the CO2 laser beam to obtain contrast, tactile effects or to perform light etching to bleach the color of the fabric.

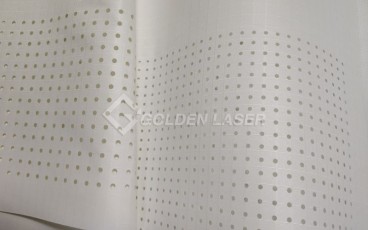

3. Laser Perforation

One of the desirable processes is laser perforation. This step allows to perforate the polyester fabrics and textiles with a tight array of the holes of the certain pattern and size. It is often required to provide ventilation properties or unique decorative effects to the end product.

Benefits of processing polyester fabric with a laser cutter

Clean and perfect cuts

Exact cutting the outline of the pre-printed design

High efficiency and exquisite tailoring

Additional advantages of goldenlaser's laser cutting machine

What is polyester fabric: Material properties and laser cutting technique

Polyester is a synthetic fibre, usually derived from petroleum. This fabric is one of the most popular textiles in the world and is used in thousands of different consumer and industrial applications. Polyester fabric has excellent characteristics such as low cost, durability, light weight, flexibility, and easy maintenance, making it suitable for manufacturing apparel, home furnishing, outdoor products and many items for industrial purposes.

Polyester absorbs the wavelength of the CO2 laser beam very well and can therefore be easily processed by laser. Laser cutting makes it possible to cut polyester at high speed and with flexibility, and even large fabrics can be completed at a fast rate. There are few design limitations with laser cutting, so more complex designs can be made without burning the fabric. Laser cutter is able to cut sharp lines and rounded corners that is difficult to do with conventional cutting tool.

Typical application industries of laser cutting polyester fabric

Recommended laser machines for cutting polyester fabric

| Laser type: | CO2 RF laser / CO2 glass laser |

| Laser power: | 150 watts, 300 watts, 600 watts, 800 watts |

| Working area: | Up to 3.5m x 4m |

| Laser type: | CO2 RF laser / CO2 glass laser |

| Laser power: | 150 watts, 300 watts, 600 watts, 800 watts |

| Working area: | Up to 1.6m x 13m |

| Laser type: | CO2 RF laser / CO2 glass laser |

| Laser power: | 150 watts |

| Working area: | 1.6m x 1.3m, 1.9m x 1.3m |

| Laser type: | CO2 RF laser |

| Laser power: | 150 watts, 300 watts, 600 watts |

| Working area: | 1.6m x 1 m, 1.7m x 2m |

| Laser type: | CO2 RF laser |

| Laser power: | 300 watts, 600 watts |

| Working area: | 1.6m x 1.6 m, 1.25m x 1.25m |

| Laser type: | CO2 glass laser |

| Laser power: | 80 watts, 130 watts |

| Working area: | 1.6m x 1m, 1.4 x 0.9m |