Would you like to get more options and availability of Goldenlaser's Laser Machines and Solutions to add value in your line? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

- English

- Chinese

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

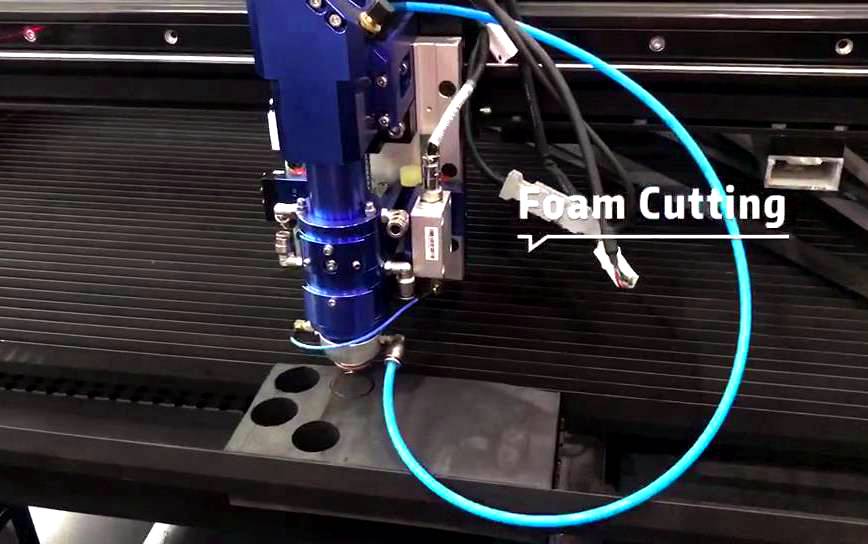

Laser Cutting of Foam

The industrial use of foam has grown significantly. Today's foam industry offers a diverse choice of materials for a variety of uses. The use of a laser cutter as a tool for cutting foam is becoming increasingly prevalent in the industry. Laser cutting technology provides a fast, professional, and cost-effective alternative to other conventional machining methods.

Foams made of polystyrene (PS), polyester (PES), polyurethane (PUR), or polyethylene (PE) are ideally suitable for laser cutting. Foam materials of different thicknesses can be easily cut with different laser powers. Lasers provide the precision that operators demand for foam cutting applications that require a straight edge.

Applicable laser processes for foam

Why cutting foam with a laser?

Cutting foam with laser is a common procedure today because there are arguments that cutting through foam can be quicker and more precise than other methods. In comparison to mechanical processes (usually punching), laser cutting offers consistent cuts without denting or damaging parts on the machinery involved in production lines--and does not require any clean-up afterwards!

Recommended laser machines for foam

- Electric lift table

- Bed size: 1300mm×900mm (51”×35”)

- CO2 glass laser tube 80 watts ~ 300 watts

-

Single head / double head

- Bed size: 1600mm×1000mm (63” ×39”)

- CO2 glass laser tube

- Gear and rack driven

- CO2 glass laser / CO2 RF laser

- High speed and acceleration

Cutting foam with a laser as a substitute tool is possible

It goes without saying that when it comes to cutting industrial foams, the benefits of using a laser over conventional cutting equipment are evident. Cutting foam with a laser offers many advantages, such as single-step processing, maximum material usage, high quality processing, clean and precise cutting, etc. The laser achieves even the smallest outlines via the use of a precise and non-contact laser cut.

However, the knife applies significant pressure to the foam, resulting in material deformation and filthy cut edges. When using a water jet to cut, moisture is sucked into the absorbent foam, which is then separated from the cutting water. Firstly, the material must be dried before it can be used in any subsequent processing, which is a time-consuming operation. With laser cutting, this step is skipped, allowing you to go back to work with the material right away. In contrast, the laser is much more compelling and is unquestionably the most effective technique for foam processing.

What kinds of foam can be laser cut?

• Polypropylene (PP) foam

• Polyethylene (PE) foam

• Polyester (PES) foam

• Polystyrene (PS) foam

• Polyurethane (PUR) Foam