We are here to help with customization options to meet your specific manufacturing needs.

Fabric Laser Cutting Solutions for Outdoor Products

In the dynamic world of outdoor product manufacturing, the quest for excellence hinges on two pivotal factors: the meticulous selection of raw materials and the adoption of advanced processing technologies. As the industry evolves, manufacturers are increasingly gravitating towards innovative solutions that not only meet but exceed the stringent standards required for outdoor products. At the forefront of this technological revolution is laser cutting, a method that has transformed the way fabrics are processed for outdoor applications.

Laser cutting stands out for its unparalleled precision and efficiency in fabric cutting, offering significant advantages over traditional methods. Its ability to produce intricate, clean cuts without fraying makes it ideal for the high-quality demands of outdoor products. This cutting-edge technology also allows for incredible design versatility, enabling the creation of complex patterns and shapes with impeccable accuracy. Furthermore, laser cutting enhances manufacturing efficiency, reducing material waste and shortening production times.

By integrating laser cutting into their fabrication processes, manufacturers in the outdoor products industry can achieve a level of detail and quality that sets their products apart, ensuring durability, functionality, and aesthetic appeal in challenging outdoor environments.

Laser Cutting Benefits

The application of laser cutting technology in the field of textile-based outdoor products offers significant features and advantages.

These characteristics and advantages make laser cutting a highly attractive technology choice in the production of outdoor textile products.

Application Examples

Laser cutting in the textile-based outdoor products sector has specific applications across various industries and materials, including:

Parachutes and Paragliders:

Laser cutting is used for precise cutting of high-performance materials like lightweight yet high-strength synthetic fabrics. These materials require precise dimensions and shapes to ensure aerodynamic performance and safety.

Tents and Awnings:

Laser cutting is used for precise cutting of synthetic fabrics like nylon or polyester, commonly used in manufacturing tents and awnings.

Sailing and Kayaking:

In the manufacturing of sailboats and kayaks, laser cutting is employed for precise handling of sailcloth and other specialty materials.

Leisure Products:

Like fabric parts of outdoor chairs, umbrellas, sunshade, and other leisure items, laser cutting ensures precise dimensions and neat edges.

Backpacks and Travel Gear:

Laser cutting can be used to cut high-strength fabrics and synthetic materials for outdoor travel products like backpacks and luggage.

Sports Equipment:

Such as outdoor sports shoes, helmet covers, protective sports gear, etc., where laser cutting offers precise and efficient cutting solutions in their production.

Outdoor Apparel:

Such as waterproof jackets, mountaineering gear, ski equipment, etc. These products often use high-tech fabrics like Gore-Tex or other waterproof-breathable materials, where laser cutting provides precise cutting.

Laser Machines Recommendation

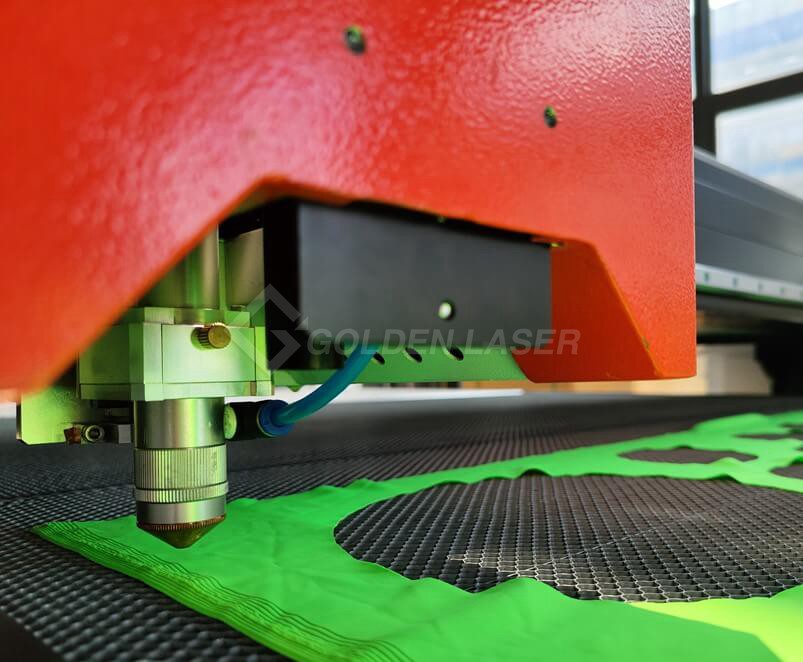

Large Format CO2 Flatbed Laser Cutting Machine

This CO2 flatbed laser cutting machine is designed for wide textile rolls and soft materials automatically and continuously cutting.

Ultra-Long Table Size Laser Cutting Machine

Extra Long Cutting Bed - Specialty 6 Meters, 10 Meters to 13 Meters bed sizes for extra long materials, such as tent, sailcloth, parachute, paraglider, sunshade…

Single Head / Double Head Laser Cutter

Working area 1600mm x 1000mm (63″ x 39″).

It is an economical CO2 laser cutter for use with both roll and sheet materials.