Would you like to get more options and availability of goldenlaser machines and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

Laser Cutting of Polypropylene (PP)

Looking for a laser cutting solution that can handle polypropylene with ease? Look no further than goldenlaser!

Our wide array of laser machines are ideally suited for large-format cutting of PP textiles and precision cutting of PP foils, as well as roll-to-roll laser kiss cutting of PP labels. Plus, our laser systems are known for their high degree of precision, speed, flexibility and stability.

Our diverse laser systems ensure that you'll find the perfect option for your needs. So why wait? Contact us today to learn more about our laser cutting solutions for polypropylene.

What are the advantages of using a laser to cut polypropylene (PP)?

Polypropylene, or PP for short, is a thermoplastic and a perfect material to use for laser processing because it absorbs the energy of a CO2 laser very easily. This means that you can cut Polypropylene (PP) with a CO2 laser cutter, providing clean, smooth and non-discolored cuts while also being able to perform various other functions such as decorative etching or even marking messages onto products!

Additionally, polypropylene is well-suited to laser kiss cutting operations, which are primarily employed in adhesives and labels manufacturing processes.

Additional advantages of goldenlaser's laser cutting machine

Laser Cutting of polypropylene (PP) - Characteristics and Uses

Polypropylene is a thermoplastic polymer made from the polymerisation of propylene. Polypropylene has high heat resistance (greater than polyethylene), good elasticity, rigidity and the ability to absorb shocks without breaking. It also has a low density (making it light), high insulating ability and good resistance to oxidants and chemicals.

Polypropylene is used in the production of automobile seats, filters, cushioning for furniture, packaging labels and technical textiles. With a laser cutting machine, polypropylene can be cut incredibly precisely and the finest possible quality. The cut has smooth and well-finished edges with no presence of burns or charring.

The contactless process made possible by the laser beam, the distortion-free cutting that occurs as a result of the process, as well as the high level of flexibility and accuracy, are all compelling reasons in favor of the employment of laser technology in the processing of polypropylene.

Typical application industries of laser cutting polypropylene (PP)

Given these properties, polypropylene has countless applications in a variety of fields. It is fair to say that there is no industrial sector that does not use polypropylene in some shape or form.

The following is a list of the most common objects made of this material.

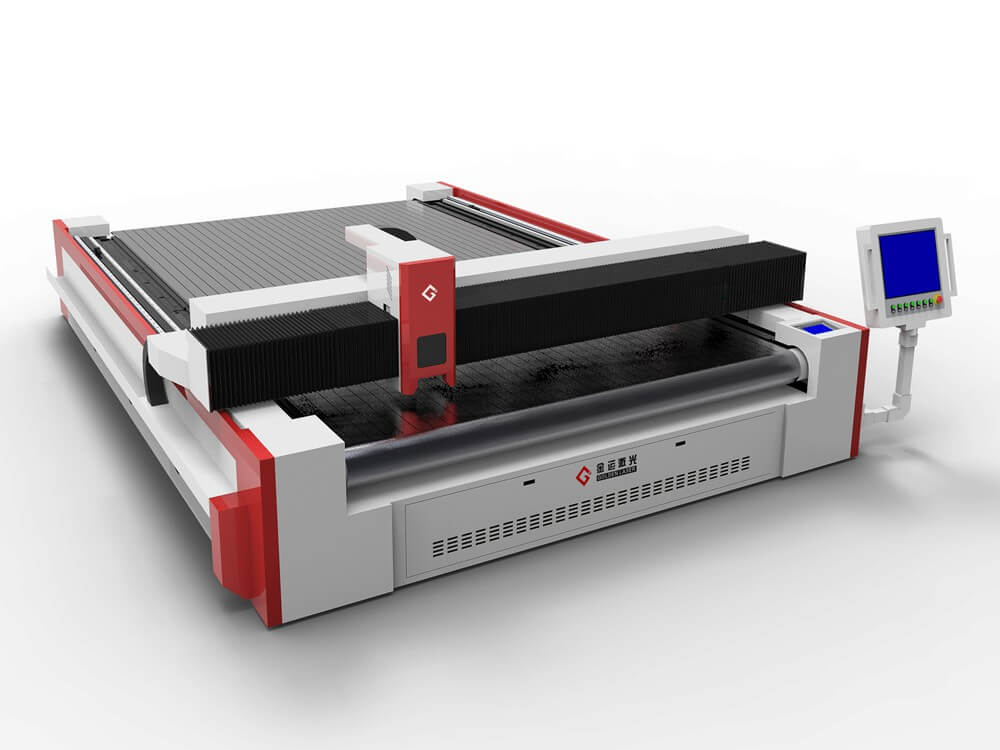

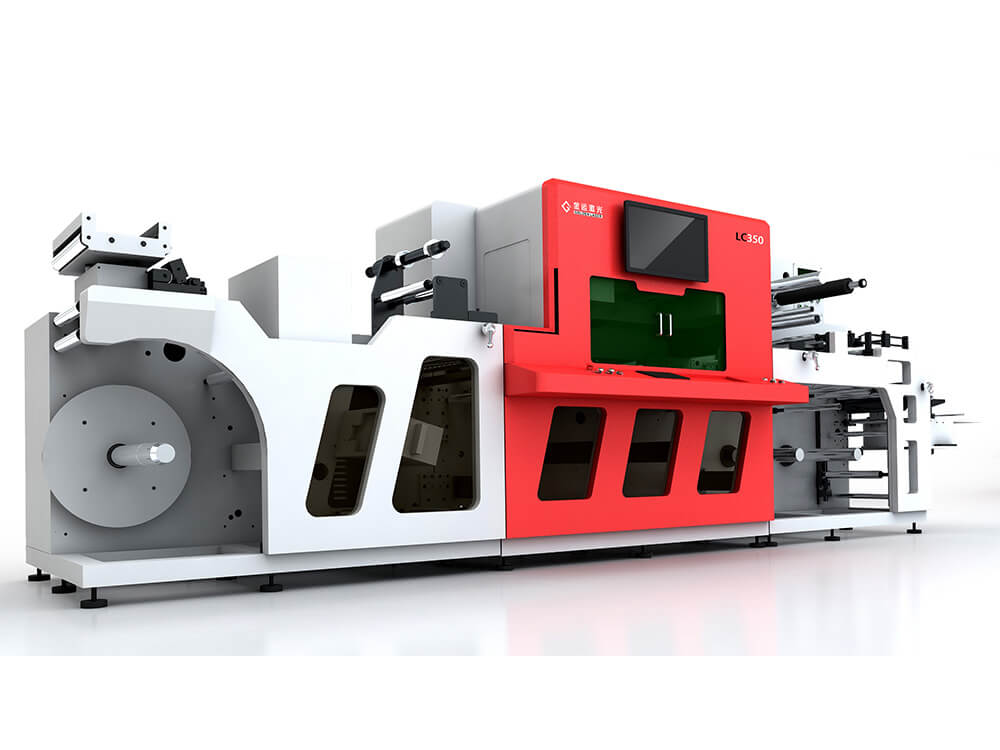

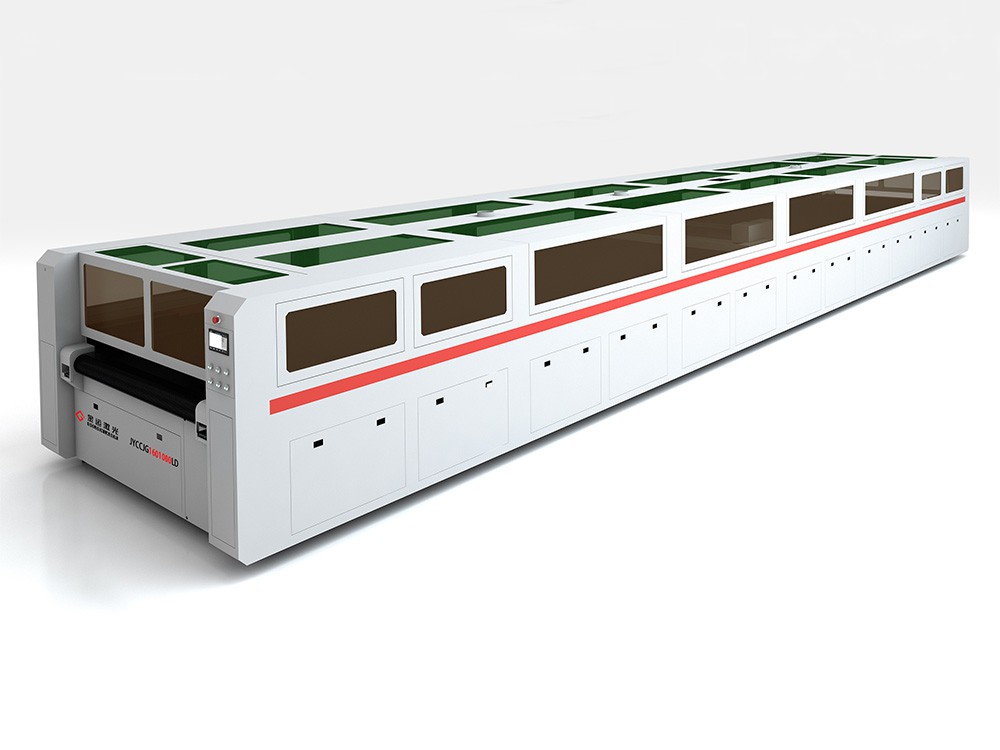

Recommended laser machines for cutting polypropylene (PP)

| Laser type: | CO2 RF laser / CO2 glass laser |

| Laser power: | 150 watts, 300 watts, 600 watts, 800 watts |

| Working area: | Up to 3.5m x 4m |

| Laser type: | CO2 RF laser |

| Laser power: | 150 watts, 300 watts, 600 watts |

| Max. web width: | 370mm |

| Laser type: | CO2 RF laser |

| Laser power: | 150 watts, 300 watts, 600 watts |

| Working area: | 1.6m x 1 m, 1.7m x 2m |

| Laser type: | CO2 RF laser |

| Laser power: | 300 watts, 600 watts |

| Working area: | 1.6m x 1.6 m, 1.25m x 1.25m |

| Laser type: | CO2 RF laser / CO2 glass laser |

| Laser power: | 150 watts, 300 watts |

| Working area: | Up to 1.6m x 10m |

| Laser type: | CO2 glass laser |

| Laser power: | 80 watts, 130 watts |

| Working area: | 1.6m x 1m, 1.4 x 0.9m |