Would you like to get more options and availability of goldenlaser systems and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

- English

- Chinese

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

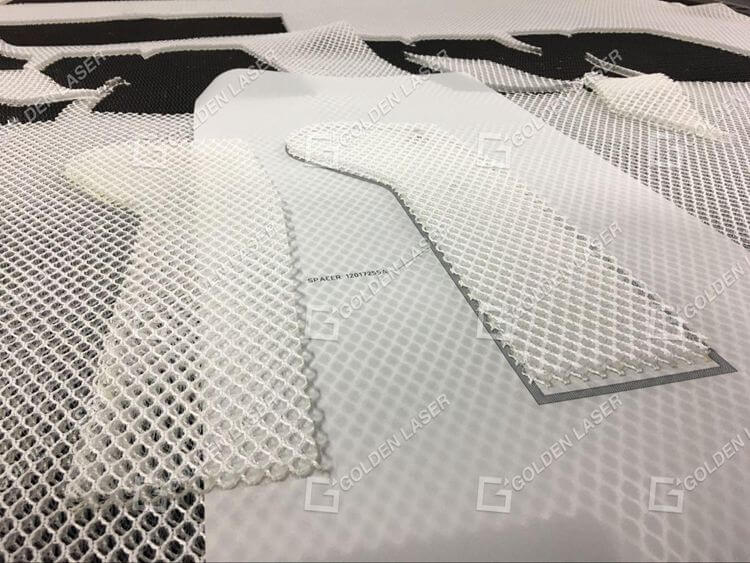

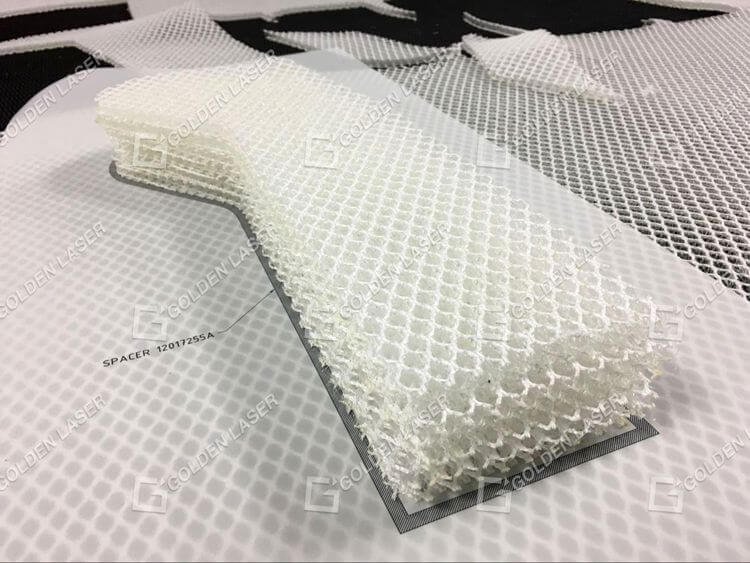

Laser Cutting of Spacer Fabrics and 3D Mesh

Goldenlaser offers laser cutting machine especially configured for spacer fabrics

Spacer fabrics are a kind of 3D manufactured textile structures that comprise of two outer textile substrates that are joined together and kept apart by an insert of spacer yarns, mostly monofilaments. Thanks to their special structure, spacer fabric shows technologically advanced characteristics, including good breathability, crush resistance, heat regulating and shape retention. However, this special three-dimensional structure of the composites poses challenges to the cutting process. The physical stresses exerted on the material by conventional machining cause it to distort, and each edge must be additionally treated to eliminate loose pile threads.

The development of manufacturing technology and application of spacer fabric is a never-ending project full of technological research, which puts forward higher requirements for the cutting processing of textile processors. Contactless laser processing has proven to be the optimum method for cutting spaced fabrics. This non-contact process minimizes fabric distortion. Consistent cutting using conventional methods is virtually impossible - the laser achieves a precise cut every time.

Benefits from using laser to cut spacer fabrics

Advantages of laser cutting machines from Goldenlaser

Material information of spacer fabrics and laser cutting method

Spacer is a highly breathable, cushioned, multi-faceted fabric, used in the practical making of a wide variety of applications ranging from healthcare, safety, military, automotive, aviation and fashion. Unlike regular 2D fabrics, Spacer uses two separate fabrics, joined by microfilament yarn, to create a breathable, 3D "microclimate" between layers. Depending on the end use, the spaced ends of the monofilament can be polyester, polyamide or polypropylene. These materials are ideally suited for cutting using the CO2 laser cutting machine. Contactless laser cutting offers maximum flexibility and shortens processing times. In contrast to knives or punches, the laser does not dull, resulting in consistently superior quality in the finished products.

Typical applications for laser cutting spacer fabrics

• Automotive - Car seats

• Orthopedic industry

• Sofa cushion

• Mattress

• Functional clothing

• Sports shoes

Related spacer fabrics suitable for laser cutting

• Polyester

• Polyamide

• Polypropylene

Other types of spacer fabrics

• 3D Mesh

• Sandwich Mesh

• 3D (Air) Spacer Mesh