Would you like to get more options and availability of goldenlaser machines and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

Laser Cutting and Engraving of Leather

Applicable laser processes for leather

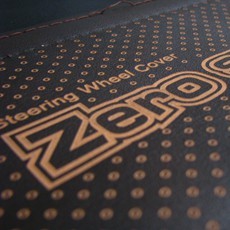

Ⅱ. Laser Engraving

Laser engraving on leather produces a textured effect similar to embossing or branding, making it easy to customize or give the end product the desired special finish.

Benefits from laser cutting and engraving leather

Laser cutting leather with clean edges

Laser engraving and marking on leather

Laser cutting small holes on leather

Highlights of goldenlaser's CO2 laser machines for the processing of leather

A basic guide to material information & laser techniques for leather

Leather is a premium material that has been used for ages, but it is also available in current production procedures. Natural and synthetic leather are employed in a variety of industries. Aside from footwear and apparel, numerous fashion and accessories are also made of leather, such as bags, wallets, handbags, belts, etc. As a result, leather serves a special purpose for designers. Furthermore, leather is often employed in the furniture sector and automobile interior fittings.

Slitting knife, die press, and hand cutting are now used in the leather cutting industry. Cutting resistant, durable leather using mechanic tools produces considerable wear. As a result, the cutting quality deteriorates with time. The advantages of contactless laser cutting are highlighted here. A variety of benefits over traditional cutting processes have made laser technology increasingly popular in recent years. Flexibility, high production speed, the ability to cut complicated geometries, simpler cutting of bespoke components, and less wastage of leather make laser cutting more and more economically appealing to use for leather cutting. Laser engraving or laser marking on leather generates embossing and allows for intriguing tactile effects.

What kinds of leather can be laser processed?

Because leather readily absorbs CO2 laser wavelengths, CO2 laser machines can process almost any type of leather and hide, including:

- Natural leather

- Synthetic leather

- Rexine

- Suede

- Microfiber

Typical applications of laser processing leather:

With the laser process, leather can be cut, perforated, marked, etched or engraved and can therefore be used in a wide range of industries, sush as:

- Footwear

- Fashion

- Furniture

- Automotive

Recommended laser machines

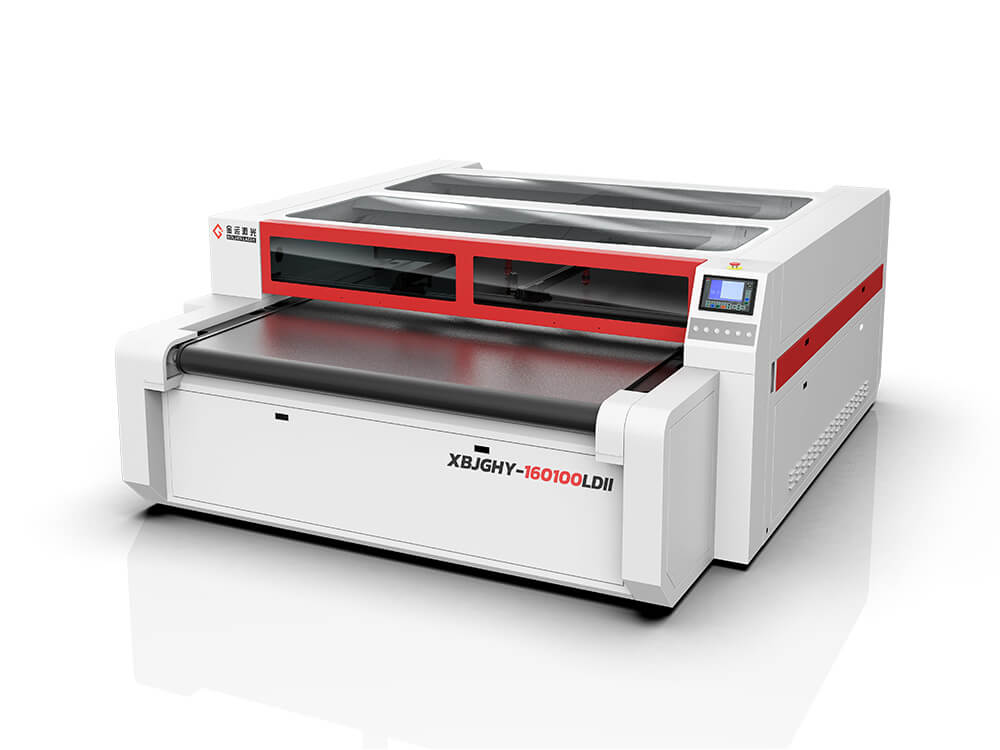

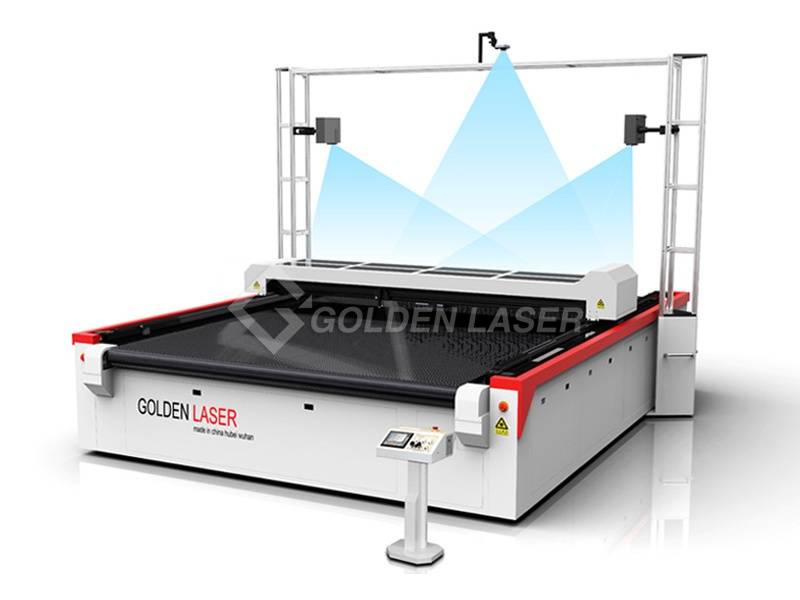

At GOLDENLASER, we manufacture a wide range laser machines ideally configured for laser cutting and laser engraving leather. From XY table to high speed Galvo system, our experts would be happy to recommend which configuration best suits your application.

| Laser type: | CO2 glass laser |

| Laser power: | 150 watts x 2 |

| Working area: | 1.6m x 1m, 1.8m x 1m |

| Laser type: | CO2 glass laser |

| Laser power: | 130 watts |

| Working area: | 1.4m x 0.9m, 1.6m x 1m |

| Laser type: | CO2 glass laser / CO2 RF metal laser |

| Laser power: | 130 watts / 150 watts |

| Working area: | 1.6m x 2.5m |

| Laser type: | CO2 RF laser |

| Laser power: | 150 watts, 300 watts, 600 watts |

| Working area: | 1.6m x 1 m, 1.7m x 2m |

| Laser type: | CO2 RF laser |

| Laser power: | 300 watts, 600 watts |

| Working area: | 1.6m x 1.6 m, 1.25m x 1.25m |

| Laser type: | CO2 RF metal laser |

| Laser power: | 150 watts, 300 watts, 600 watts |

| Working area: | 900mm x 450mm |