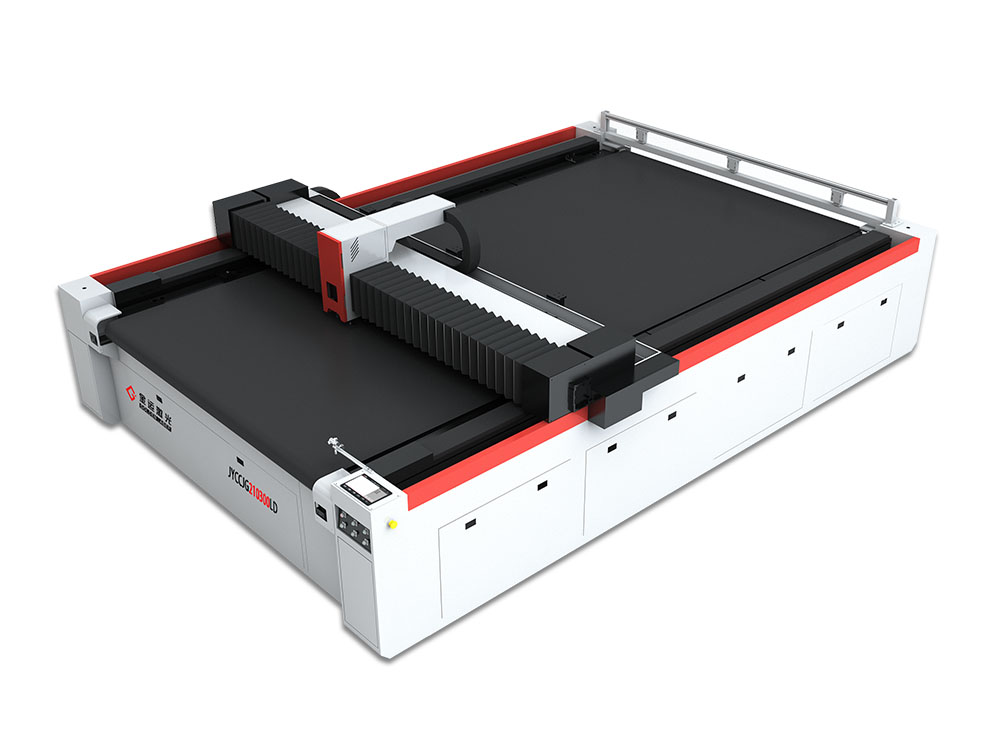

Carpet Laser Cutting Machine

Model No.: JYCCJG-210300LD

Introduction:

Carpet laser cutting bed for non-woven, polypropylene fiber, blended fabric, leatherette and more carpets cutting. Conveyor working table with the auto feeding. fast and continuous cutting. Servo motor driving. High efficiency and good processing effect. Optional smart nesting software can do fast and material-saving nesting on the graphics to be cut. Various large format working areas optional.

Machine Features

• Open-type or closed type design. Processing format 2100mm × 3000mm. Servo motor driving. High efficiency and good processing effect.

• Particularly suitable for large format continuous line engraving as well as cutting sizes and shapes of various carpets, mats and rugs.

• Conveyor working table with the auto-feeding device (optional). Fast and continuous cutting of carpet.

• The laser cutting machine can do extra-long nesting and full format cutting on a single pattern that is longer than the cutting format of the machine.

• Optional smart nesting software can do fast and material-saving nesting on the graphics to be cut.

• 5-inch LCD screen CNC operating system supports multiple data transmission mode and can run in offline and online modes.

• Following up exhaust suction system to synchronize laser head and exhaust suction system, good suction effects, saving energy.

• Red light positioning device prevents position deviation of the material in the feeding process and ensures high processing quality.

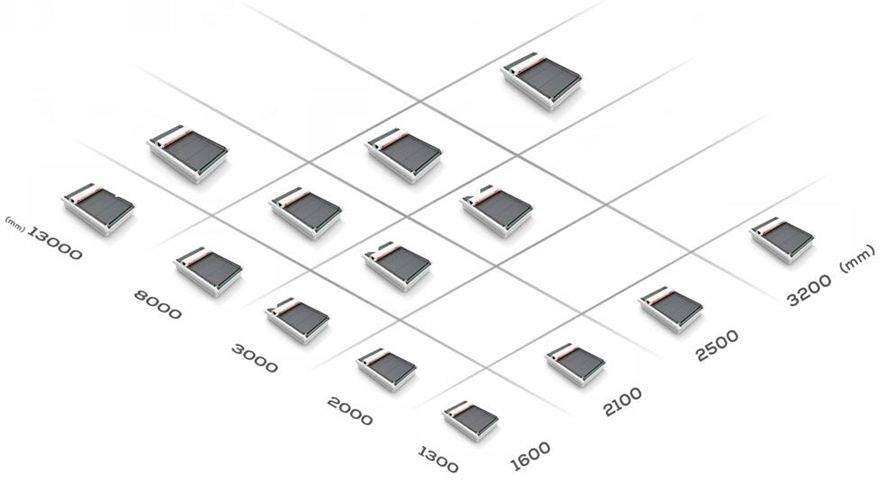

• Users can also choose formats of 1600mm × 3000mm, 4000mm x 3000mm, 2500mm × 3000mm working table and also other customized format of working table.

Quick Specifications

Main Technical Parameter of the JYCCJG210300LD CO2 Laser Cutting Machine

| Laser type | CO2 laser |

| Laser power | 150W / 300W / 600W |

| Working area (WxL) | 2100mmx3000mm (82.6”x118”) |

| Working table | Conveyor working table |

| Positioning accuracy | ±0.1mm |

| Power supply | AC220V ± 5% 50Hz/60Hz |

| Format supported | AI, BMP, PLT, DXF, DST |

Watch Laser Cutting of Carpet in Action!

What are the advantages of laser cutting of carpets?

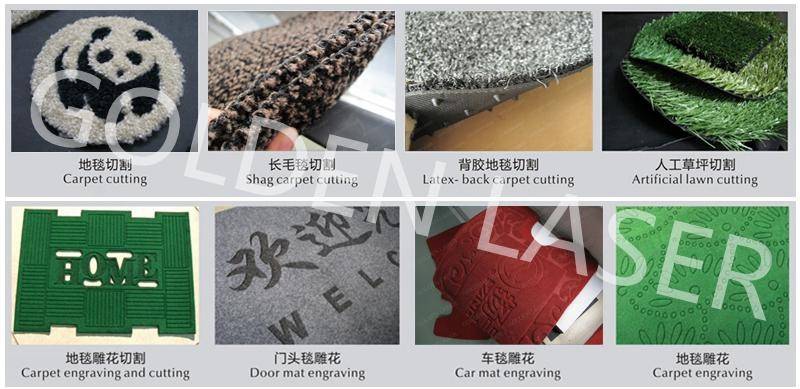

Laser Cutting Carpet Samples

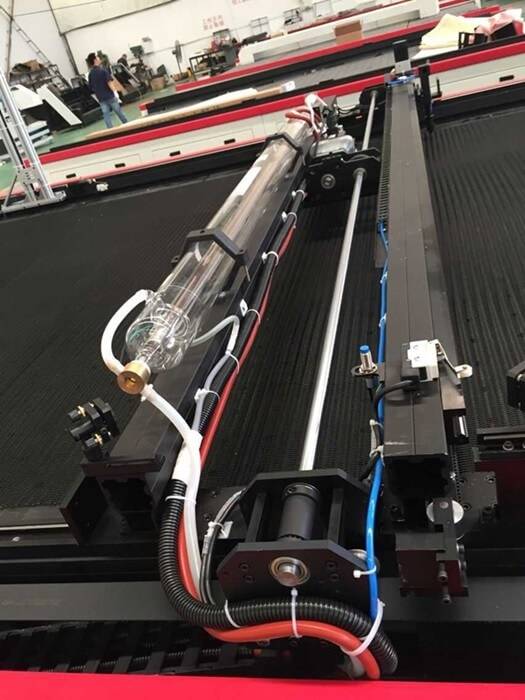

GOLDEN LASER - CO2 Laser Cutting Machine in Production

10 meters extra-long laser cutting machine

Technical Parameter

| Laser type | CO2 DC glass laser 150W / 300W |

| CO2 RF metal laser 150W / 300W / 600W | |

| Cutting area | 2100×3000mm |

| Working table | Conveyor working table |

| Working speed | Adjustable |

| Positioning accuracy | ±0.1mm |

| Motion system | Offline mode servo motor control system, 5 inch LCD screen |

| Cooling system | Constant temperature water chiller |

| Power supply | AC220V ± 5% 50Hz/60Hz |

| Format supported | AI, BMP, PLT, DXF, DST etc. |

| Standard collocation | 1 set of 550W top exhaust suction machine, 2 sets of 3000W bottom exhaust suction machines, mini air compressor |

| Optional collocation | Auto-feeding system, red light positioning |

| *** Note: As products are constantly updated, please contact us for the latest specifications. *** | |

WORKING AREAS CAN BE CUSTOMIZED

|

GOLDEN LASER – Flatbed CO2 Laser Cutting Machine |

|

|

Model NO. |

Working Area |

|

CJG-160250LD |

1600mm×2500mm (63” ×98.4”) |

|

CJG-160300LD |

1600mm×3000mm (63” ×118.1”) |

|

CJG-210300LD |

2100mm×3000mm (82.7” ×118.1”) |

|

CJG-210400LD |

2100mm×4000mm (82.7” ×157.4”) |

|

CJG-250300LD |

2500mm×3000mm (98.4” ×118.1”) |

|

CJG-210600LD |

2100mm×6000mm (82.7” ×236.2”) |

|

CJG-210800LD |

2100mm×8000mm (82.7” ×315”) |

|

CJG-2101100LD |

2100mm×11000mm (82.7” ×433”) |

|

CJG-300500LD |

3000mm×5000mm (118.1” ×196.9”) |

|

CJG-320500LD |

3200mm×5000mm (126” ×196.9”) |

|

CJG-320800LD |

3200mm×8000mm (126” ×315”) |

Applicable Materials and Industry

Suitable for non-woven, polypropylene fiber, blended fabric, leatherette and other carpets.

Suitable for various carpets cutting.

Why Laser for Carpet Cutting?

Cutting commercial and industrial carpet is another great CO2 laser application. In many cases, synthetic carpet is cut with little or no charring, and heat generated by the laser acts to seal edges to prevent fraying. Many specialized carpet installations in motor coaches, aircraft, and other small square-footage applications benefit from the precision and convenience of having the carpet precut on a large-area flatbed laser cutting system. Using a CAD file of the floor plan, the laser cutter can follow the outline of walls, appliances, and cabinetry – even making cutouts for table support posts and seat mounting rails as required.

The first photo shows a section of carpet with a support post cutout trepanned in the center. The carpet fibers are fused by the laser cutting process, which prevents fraying – a common problem when carpet is mechanically cut.

The second photo illustrates the cleanly cut edge of the cutout section. The blend of fibers in this carpet exhibit no signs of melting or charring.

The carpet laser cutting machine cuts different format and different sizes of all carpet materials. Its high efficiently and high performance will improve your production quantity, save time and save cost.