High Speed Galvo Laser Engraving Machine for Leather Shoe

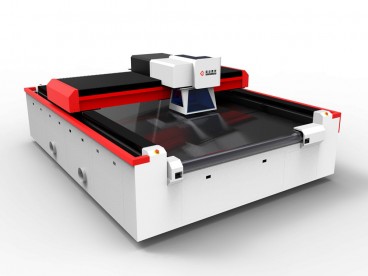

Model No.: ZJ(3D)-9045TB

Introduction:

- CO2 RF metal laser 150W 300W 600W

- 3D dynamic galvanometer control system.

- Automatic up and down Z axis.

- Automatic shuttle zinc-iron alloy honeycomb working table.

- Use-friendly 5 inches LCD screen CNC system.

- Rear exhaust suction system.

- High speed engraving cutting and perforating of leather, shoe uppers, fabrics, jeans labels, etc.

Galvo Laser Engraving Machine

(3D dynamic focus)

CO2 LASER PROCESSING SYSTEM FOR LEATHER PERSONALIZED DESIGN

FOR Shoes / Bags / Belts / Labels / Garment Accessories

Model No.: ZJ(3D)-9045TB

CO2 RF metal laser 150W 275W 500W.

3D dynamic galvanometer control system.

Automatic up and down Z axis.

Automatic shuttle zinc-iron alloy honeycomb working table.

Rear exhaust suction system.

Model No.: ZJ(3D)-4545

ZJ(3D)4545 Galvo laser engraving system is an upgraded version of the ZJ(3D)-9045TB, which adds the robot arm for auto loading & unloading system and the CCD camera positioning system for full automation.

Technological Features

Fast

Single graphic process is completed in a few seconds.

No molds

Saving time, cost and space for tooling.

Unlimited design

Laser processing a variety of graphic designs.

Easy to use

Simplify workers’ operations and make it easier to get started.

Automatic processing

Reducing management costs, and requiring only regular maintenance.

Contactless process

The finished product has good consistency, without mechanical deformation.

Watch Galvo Laser Engraving System ZJ(3D)-9045TB in Action!

ZJ(3D)-9045TB High Speed Galvo Laser Machine Technical Parameter

| Laser type | CO2 RF metal laser tube |

| Laser power | 150W / 300W / 600W |

| Working area | 900mmX450mm |

| Working table | Shuttle Zn-Fe alloy honeycomb working table |

| Working speed | Adjustable |

| Positioning Accuracy | ±0.1mm |

| Motion system | Offline 3-D dynamic galvanometer motion control system, 5 inch LCD screen |

| Cooling system | Constant temperature water chiller |

| Power supply | AC220V±5% 50/60HZ |

| Format supported | AI, BMP, PLT, DXF, DST etc. |

| Standard collocation | 2 sets of 1100W exhaust fans, foot switch |

| Optional collocation | Red light positioning system |

| *** Note: As products are constantly updated, please contact us for latest specifications. *** | |

• ZJ(3D)-9045TB High Speed Galvanometer Laser Engraving Machine for Leather Shoes

• ZJ(3D)-160100LD Multifunction Laser Engraving Punching Hollowing and Cutting Machine

• ZJ(3D)-170200LD High Speed Galvo Laser Cutting and Perforating Machine for Jersey

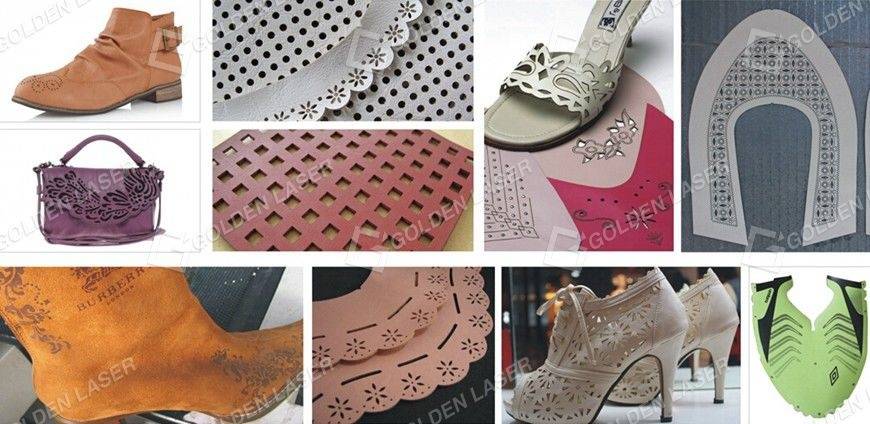

Laser Engraving Cutting Application

Laser applicable industries: shoes, home textile upholstery, furniture industry, fabric furnishings, garment accessories, apparel & clothing, automotive interiors, car mats, carpet mat rugs, luxurious bags, etc.

Laser applicable materials: Laser engraving cutting punching hollowing PU, PVC, artificial leather, synthetic leather, fur, genuine leather, imitation leather, natural leather, textile, fabric, suede, denim and other flexible materials.

<< More Samples of Leather Laser Engraving Cutting Hollowing

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?