Galvo Laser Cutting Engraving Machine for Paper Wedding Invitation Cards

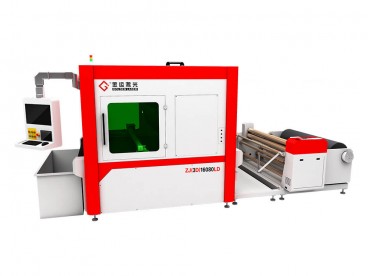

Model No.: ZJ(3D)-9045TB

Introduction:

Laser cutting is a quick and easy process that can be used for processing intricate paper pattern, paperboard and cardboard for wedding invitations, digital printing, packaging prototype construction, model making or scrapbooking.

Even engraving of paper with the laser delivers impressive results. Whether logos, photographs or ornaments – there are no limits in graphic design. Quite the contrary: Surface finishing with the laser beam increases the freedom of design.

High Speed Galvo Laser Cutting Engraving Machine for Paper

ZJ(3D)-9045TB

Features

• Adopting the world’s best optical transmitting mode, featured with super precise engraving with higher speed.

• Supporting almost all types of non-metal material engraving or marking and thin material cutting or perforating.

• Germany Scanlab Galvo head and Rofin laser tube make our machines ever more stable.

• 900mm ×450mm working table with professional control system. High efficiency.

• Shuttle working table. Loading, processing and unloading can be finished at the same time, largely increasing working efficiency.

• Z axis lifting mode ensures 450mm×450mm one time working area with perfect processing effect.

• Vacuum absorbing system perfectly solved the fumes problem.

Highlights

√ Small Format / √ Material in Sheet / √ Cutting / √ Engraving / √ Marking / √ Perforation / √ Shuttle Working TableHigh Speed Galvo Laser Cutting Engraving Machine ZJ(3D)-9045TB

Technical Parameters

| Laser type | CO2 RF metal laser generator |

| Laser power | 150W / 300W / 600W |

| Working area | 900mm×450mm |

| Working table | Shuttle Zn-Fe alloy honeycomb working table |

| Working speed | Adjustable |

| Positioning Accuracy | ±0.1mm |

| Motion system | 3D dynamic offline motion control system with 5” LCD display |

| Cooling system | Constant temperature water chiller |

| Power supply | AC220V ± 5% 50/60Hz |

| Format supported | AI, BMP, PLT, DXF, DST, etc. |

| Standard collocation | 1100W exhaust system, foot switch |

| Optional collocation | Red light positioning system |

| *** Note: As products are constantly updated, please contact us for latest specifications. *** | |

Material in Sheet Marking and Perforation Laser Application

GOLDEN LASER – Galvo Laser Marking Systems Optional Models

• ZJ(3D)-9045TB • ZJ(3D)-15075TB • ZJ-2092 / ZJ-2626

High Speed Galvo Laser Cutting Engraving Machine ZJ(3D)-9045TB

Applied Range

Suitable for but not limited to paper, cardboard, paperboard, leather, textile, fabric, acrylic, wood, etc.

Suitable for but not limited to wedding invitation cards, packaging prototype, model making, shoes, garments, labels, bags, advertising, etc.

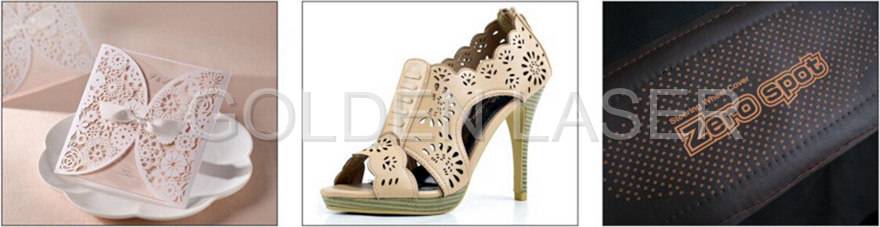

Sample Reference

Laser Cutting Paper

Laser cut intricate paper pattern with GOLDENLASER Galvo laser system

The precision and accuracy of an GOLDENLASER Laser system allows you to cut intricate lace patterns, fretwork, text, logos, and graphics from any paper product. The detail that an laser system is able to reproduce makes it the perfect tool for anyone using traditional methods for dye cuts and paper crafts.

Laser Cutting Paper & Cardboard & Paperboard

Cutting, scribing, grooving and perforating with GOLDENLASER laser paper cutters

Laser cutting is a quick and easy process that can be used for processing paper, paperboard and cardboard for wedding invitations, digital printing, packaging prototype construction, model making or scrapbooking. The benefits offered by a laser paper cutting machine open up new design options for you, which will set you apart from the competition.

Even engraving of paper with the laser delivers impressive results. Whether logos, photographs or ornaments - there are no limits in graphic design. Quite the contrary: Surface finishing with the laser beam increases the freedom of design.

Suitable materials

Paper (fine or art paper, uncoated paper) up to 600 grams

Paperboard

Cardboard

Corrugated cardboard

Material overview

Laser-cut invitation card with intricate design

Laser Cutting for Digital Printing

Laser cutting of paper with incredible details

Laser cutting of invitations and greeting cards

Laser cutting of paper and cardboard: Refining the cover

How does laser cutting and laser engraving of paper work?

Lasers are particularly well suited for realizing even the finest geometries with maximum precision and quality. A cutting plotter cannot fulfill these requirements. Laser paper cutting machines not only allow for cutting even the most delicate paper forms, but also engraving logos or pictures can be implemented effortlessly.

Does the paper burn during laser cutting?

Equally as wood, which has a similar chemical composition, paper is evaporated suddenly, which is called sublimation. In the area of the cutting clearance, the paper escapes in gaseous form, which is visible in the form smoke, at a high rate. This smoke transports the heat away from the paper. Therefore, the thermal load on the paper near the cutting clearance is relatively low. This aspect is exactly what makes laser cutting of paper so interesting: The material will have no smoke residues or burnt edges, even for the finest contours.

Do I require special accessories for laser cutting of paper?

An optical detection system is the ideal partner if you wish to refine your printed products. With the camera system, the contours of printed materials are cut perfectly. In this manner, even flexible materials are cut absolutely accurately. No time-consuming positioning is required, distortions in the impression are detected, and the cutting path is adapted dynamically. By combining the optical registration mark detection system with a laser cutting machine from GOLDENLASER, you can save up to 30% in process costs.

Do I have to fixate the material on the working surface?

No, not manually. To achieve optimal cutting results, we recommend the use of a vacuum table. Thin or corrugated materials, such as e. g. cardboard, are thus positioned flat on the working table. The laser does not exert any pressure on the material during the process, clamping or any other type of fixation is therefore not required. This saves time and money during the preparation of the material and, last but not least, prevents crushing of the material. Thanks to these benefits, the laser is the perfect cutting machine for paper.