Would you like to get options and availability in terms of laser cutting systems and solutions for your business practices? Please fill out the form below. Our specialists are always happy to help and will get back to you promptly.

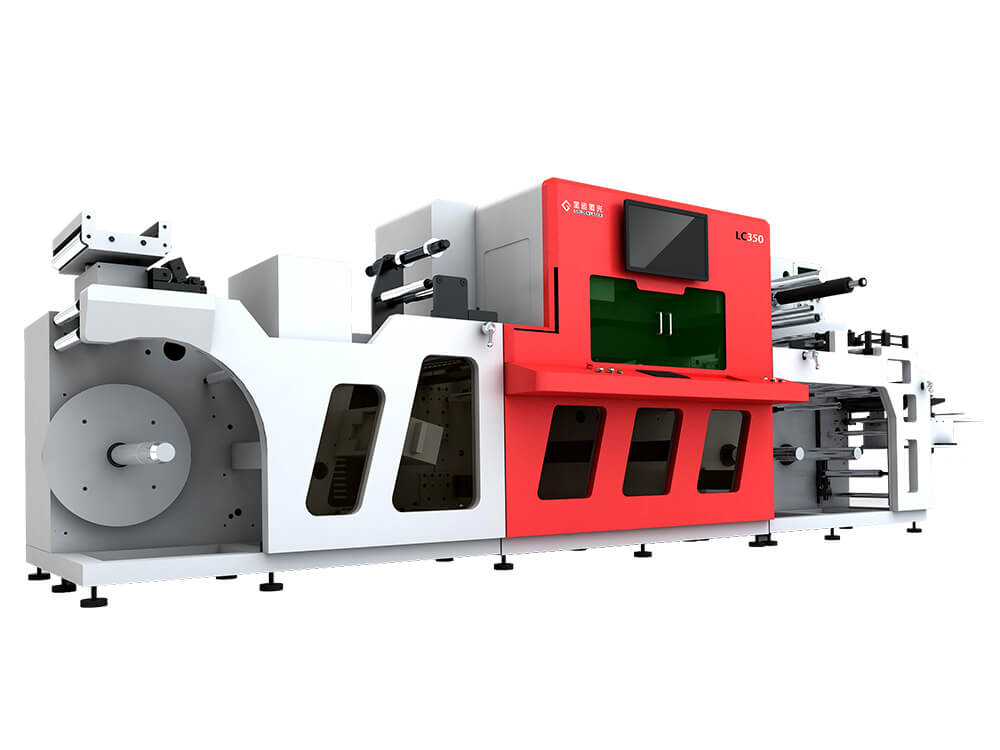

Laser Cutting Machine for Label Finishing

Recommended Machines

Technical specifications of Golden Laser's two standard models of label laser cutting machines

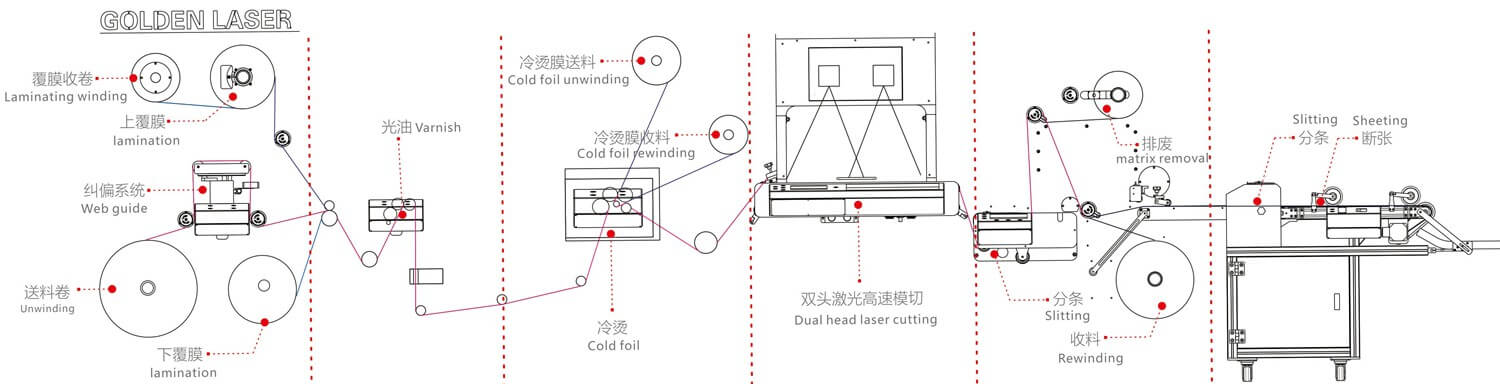

Modular Design

Configurations

Unwinder with closed-loop tension control

Max unwinder diameter: 750mm

Electronic web guide with ultrasonic edge guide sensor

With two pneumatic shafts and unwind/rewind

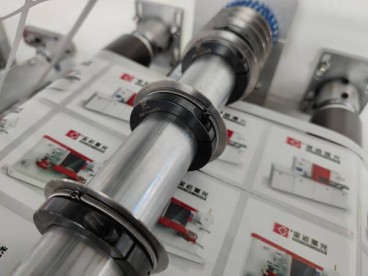

Can be equipped with one or two laser scan heads. Three or more laser heads can be customized; Multi-station laser workstation (Galvo laser and XY gantry laser) are available.

Optional shear slitter or razor blade slitter

Rewinder or Dual rewinder. With closed-loop tension control system ensures continuous stable tension. 750 mm maximum rewind diameter.

For the digital label printing industry, Golden Laser's laser die cutters can work well with all pre-press and post-press systems (e.g. rotary die cutting, flat bed die cutting, screen printing, flexo printing, digital die cutting, varnish, laminating, hot stamping, cold foil, etc.). We have long-standing partners who can supply these modular units. Goldenlaser's in-house developed software and control system are fully compatible with them.

Converting Options

LC350 / LC230 Label Laser Cutting Machine Features

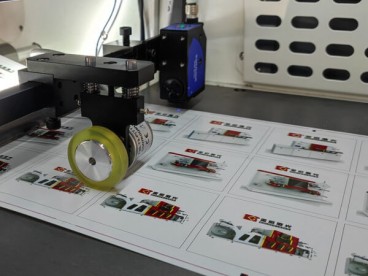

Optional camera registration and bar code (QR code) reader system

The benefits of laser die cutting

Quick turnaround

Short runs can be processed quickly. You can offer same day delivery for a wide range of labels.

Cost saving

No tooling required, saving capital investment, setup time, waste and storage space.

No limitation of graphics

Labels with highly complex images can be laser cut speedily.

High speed

Galvanometric system allows laser beam to move very quickly. Expandable dual lasers with cutting speed up to 120 m/min.

Work a wide range of material

Glossy paper, matt paper, cardboard, polyester, polypropylene, BOPP, film, reflective material, abrasives, etc.

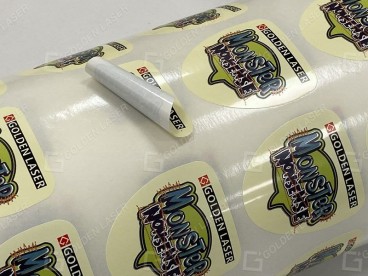

Suitable for different kinds of work

Cutting, kiss-cutting, perforating, micro perforating, engraving, marking, ...

Label laser cutting applications

→ Applicable Materials:

PET, paper, coated paper, glossy paper, matte paper, synthetic paper, kraft paper, polypropylene (PP), TPU, BOPP, plastic, film, PET film, microfinishing film, lapping film, double-sided tape, 3M VHB tape, reflective tape, etc.

→ Application Fields:

Labels / Stickers & Decals / Printing & Packaging / Films & Tapes / Heat Transfer Films / Retro Reflective Films / Adhesive / 3M Tapes / Industrial Tapes / Abrasive Materials / Automotive / Gaskets / Membrane Switch / Electronics, etc.