We will tailor the best solution to meet your specific web converting requirements!

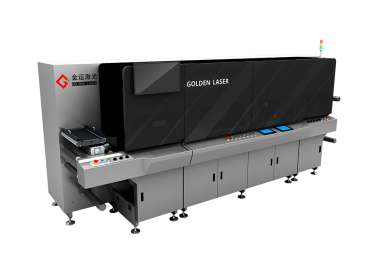

Multi-Station Laser Die Cutting Machine

Model No.: LC800

Introduction:

The multi-station laser die cutting system LC-800 can be customized with multiple laser stations according to processing needs, enabling one-stop completion of various complex die-cutting processes and improving production efficiency.

Boosting Web Converting Efficiency with Exceptional Flexibility and Speed

LC800 Multi-Station Web Laser Die-Cutting System: 800mm Web Width, Flexible Roll-to-Roll/Roll-to-Sheet Processing for High-Efficiency Smart Converting

The LC800 Multi-Station Web Laser Die-Cutter is an advanced solution designed for demanding web material processing. Featuring a large 800mm web width, this system handles a wide range of materials. Built with customizable multi-laser processing stations, the LC800 allows users to perform many complex converting steps in one smooth operation. Its great flexibility comes from supporting both Roll-to-Roll and Roll-to-Sheet processing methods, effectively meeting the various needs of modern web product manufacturing, greatly increasing production speed, and lowering operating costs.

Key Performance Features

The LC800 has an 800mm-wide processing area, easily handling larger web materials and increasing the types of materials you can use, making the system more adaptable.

A key benefit of the LC800 is its very adjustable processing station design. Users can easily plan and set up multiple separate laser processing units to perfectly match their web product's production steps. Whether the job needs different types of cutting one after another, detailed perforations, precise scoring lines, or extra functions, the LC800 offers a simple and effective answer. This custom setup reduces the time materials spend moving between steps, leading to significant improvements in overall production speed.

The LC800 is more than just a laser cutter; it's a smart, combined converting platform. By easily using different laser types and function units, the system can perform many complex converting tasks at the same time or one after the other, including:

This capability to complete multiple processes in a single pass eliminates the cumbersome steps of repeated handling and repositioning inherent in traditional methods, dramatically shortening production cycles and enhancing throughput.

The LC800 offers exceptional processing mode flexibility, allowing seamless switching between Roll-to-Roll and Roll-to-Sheet configurations to suit different production demands:

This dual-mode flexibility, combined with the 800mm web width, enables the LC800 to address a broader spectrum of web converting applications, maximizing equipment utilization.

The LC800's multi-station and multi-process integration, coupled with flexible web processing modes and the 800mm web width, significantly increases output per unit time and shortens lead times. Simultaneously, it reduces capital expenditure on multiple machines and minimizes labor costs, along with material waste associated with repeated handling, ultimately delivering a comprehensive boost in production efficiency and lower operational expenses.

Choose the LC800 and Benefit From:

Applications

The LC800 Multi-Station Web Laser Die-Cutting System, with its 800mm web width, highly efficient and flexible processing modes, and powerful multi-process integration capabilities, is your ideal choice for achieving high-performance, intelligent web converting.

Contact us today to learn more about the LC800 Multi-Station Web Laser Die-Cutting Machine.

Technical Parameters of LC800 Laser Die Cutting Machine

| Model No. | LC800 |

| Max. Web Width | 800mm / 31.5″ |

| Max. Web Speed | Depending on laser power, material and cut pattern |

| Accuracy | ±0.1mm |

| Laser Type | CO2 RF metal laser |

| Laser Power | 150W / 300W / 600W |

| Laser Beam Positioning | Galvanometer |

| Power Supply | 380V three phase 50/60Hz |

*** Note: As products are constantly updated, please contact us for the latest specifications. ***

Golden Laser Die-Cutting Machine Model Summary

| Roll-to-Roll Type | |

| Standard Digital Laser Die Cutter with Sheeting Function | LC350 / LC520 |

| Hybrid Digital Laser Die Cutter (Roll to roll and Roll to sheet) | LC350F / LC520F |

| Digital Laser Die Cutter for High-end Color Labels | LC350B / LC520B |

| Multi-station Laser Die Cutter | LC800 |

| MicroLab Digital Laser Die Cutter | LC3550JG |

| Sheet-Fed Type | |

| Sheet Fed Laser Die Cutter | LC1050 / LC8060 / LC5035 |

| For Film and Tape Cutting | |

| Laser Die Cutter for Film and Tape | LC350 / LC1250 |

| Split-type Laser Die Cutter for Film and Tape | LC250 |

| Sheet Cutting | |

| High-precision Laser Cutter | JMS2TJG5050DT-M |

The LC800 Multi-Station Web Laser Die-Cutting Machine is versatile and can be applied across a wide range of industries for processing various flexible web materials. Here are some key application industries and the types of materials commonly processed:

Application Industries:

- Label Printing & Converting: Manufacturing of various types of labels, including pressure-sensitive labels, self-adhesive labels, in-mold labels, and more.

- Packaging: Production of flexible packaging components, pouches, sleeves, and carton blanks (kiss-cutting and scoring).

- Electronics: Precision cutting and converting of flexible circuits (FPC), shielding materials, insulation films, and adhesive components used in electronic devices.

- Automotive: Manufacturing of interior trim components, gaskets, seals, and adhesive parts used in vehicle assembly.

- Medical & Healthcare: Converting of medical tapes, wound care dressings, diagnostic test strips, and transdermal patches.

- Textiles & Apparel: Cutting and marking of technical textiles, sportswear components, and garment labels.

- Signage & Graphics: Production of flexible signage, decals, stickers, and promotional materials.

- Industrial Applications: Converting of tapes, films, foams, and other flexible materials for various industrial uses, such as insulation, sealing, and bonding.

- Abrasive (Sandpaper) Industry: Manufacturing of sanding discs, belts, and custom shapes for various sanding applications.

Materials Processed:

- Films: PET, PVC, BOPP, PE, PP, Polyimide (Kapton), and other plastic films (clear, metallized, coated).

- Adhesive Materials: Single and double-sided adhesive tapes, label stock with various face stocks (paper, film), and specialty adhesive materials.

- Paper & Cardboard: Coated and uncoated paper, thermal transfer paper, synthetic paper, and thin cardboard (for kiss-cutting and scoring applications).

- Foams: Thin plastic foams, rubber foams, and other flexible foam materials.

- Textiles: Woven and non-woven fabrics, technical textiles, and synthetic leather.

- Flexible Circuits (FPC): Polyimide-based and other flexible circuit materials.

- Magnetic Materials: Thin flexible magnetic sheets and strips.

- Release Liners: Silicone-coated paper and films.

- Abrasive Materials (Sandpaper): Paper-backed, cloth-backed, and film-backed sandpaper with various grits.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?