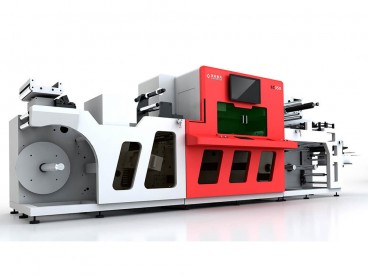

Sheet Fed Laser Cutter

Model No.: LC5035 (Single Head)

Introduction:

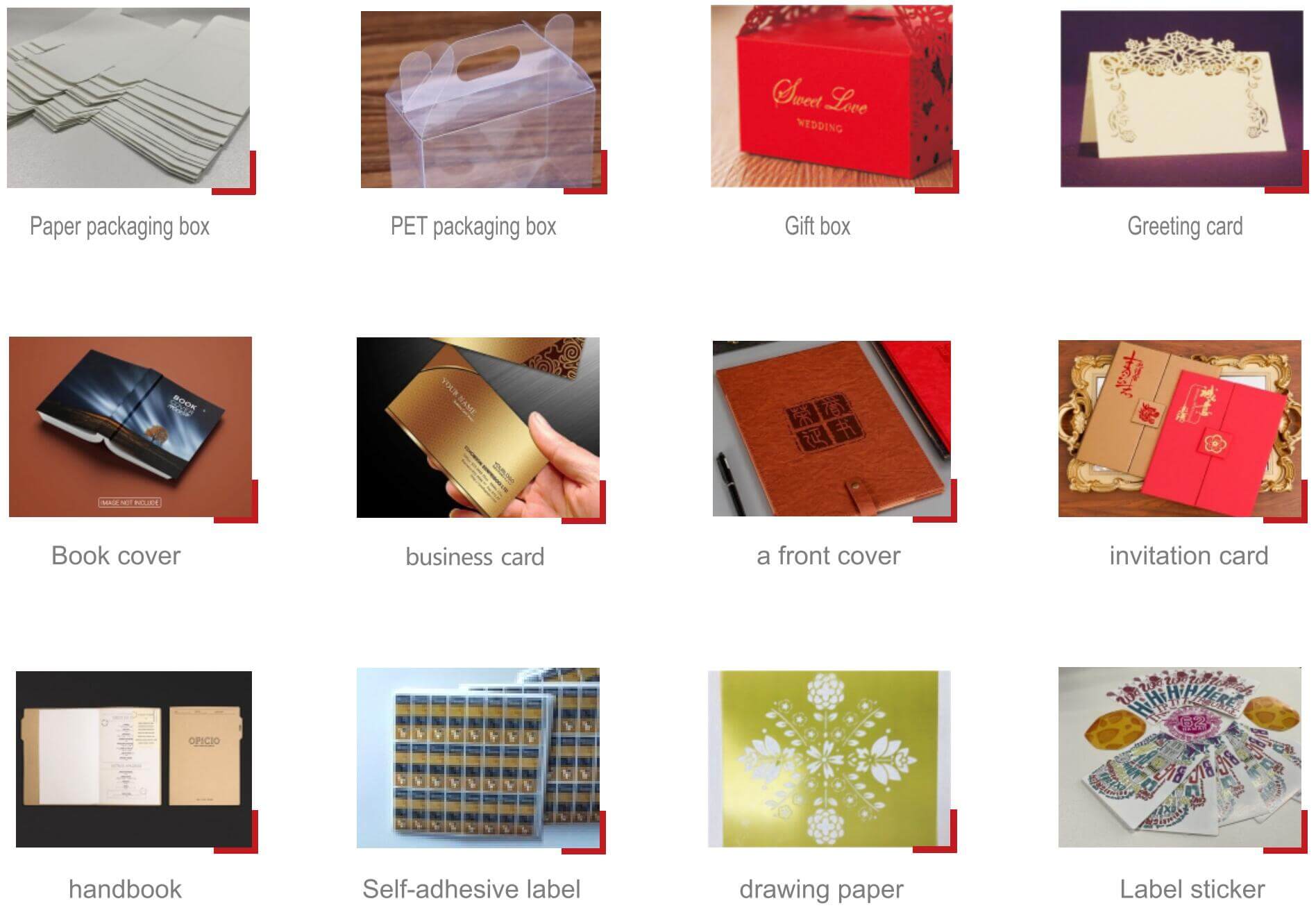

Expand production versatility by integrating a Golden Laser LC5035 into your sheet-fed operations and gain the ability to full cut, kiss cut, perforate, etch and score in a single station. The ideal solution for paper products like labels, greeting cards, invitations, folding cartons, promotional materials, and more. Golden Laser’s digital laser finishing solutions offer flexibility and infinite variety without the cost, delays, and limitations of hard tooling.

- Working area : 500mmx350mm

- Processing form : Single sheet / Continuous

- Laser type : CO2 RF laser

- Laser power : 200W / 300W / 600W Single head

Sheet-Fed Laser Cutting Machine

A high-speed laser cutting system combined with an automatic sheet feeder enables users to handle the sheet material from media loading to collecting in a continuous, unattended and efficient manner.

How LC5035 Sheet-Fed Laser Cutter Works?

Create precise, eye-catching designs while maximizing material usage, minimizing manual steps, and reducing down time.

LC5035 sheet-fed laser cutter is designed for processing paper materials for print markets, although other applications are available. In the sheet-fed system, material is loaded into the work area automatically by a sheet loader. After the sheet is loaded, registration sensors and vision cameras identify the location of printed details and the sheet’s orientation, and trigger the lasers to cut, score, perforate, or kiss-cut the material. The finished sheet is then removed from the work area either manually or automatically.

Vision cameras are integrated into the laser system to pinpoint print details for the most accurate placement of the laser cut line relative to the pattern. Alternately, registration sensors can detect printed fiducials to guide the laser beam for precise cuts. Golden Laser can also integrate bar code readers into the system for variable print laser processing and instant order change, giving you superior flexibility and dramatically reducing waste and down time.

One of the common disadvantages of sheet-fed laser systems is the manual labor required to load processing sheets and unload finished parts. Golden Laser solves such manpower requirements through automation. Our systems can integrate directly with the sheet feeder equipment for off-line digital conversion, and incorporate conveyors into the system to create a total in-line solution. Conveyors or sheet feeders can also be combined with stackers or pick-and-place robots to fully automate the line from in-feed to sorting.

Benefits

Sheet-to-Sheet Laser Cutting

Our sheet-to-sheet systems give you superior speed and processing capabilities for applications with a consistent sheet size and a one-to-one relationship between the raw sheet and the finished part. Incorporating a stacker to organize processed parts takes you even closer to finished product.

Sheet-to-Part Laser Cutting

Our sheet-to-part systems increase your flexibility by processing variable patterns or multiple parts from a single sheet. Because sorting and stacking finished parts for packaging is of greater concern with sheet-to-part systems, Golden Laser helps you incorporate customized material handling solutions to minimize manual intervention.

Watch LC5035 Sheet Fed Laser Cutter Working in Action!

Technical Parameters of Sheet Fed Laser Cutting Machine LC5035

| Model | LC5035 |

| Process type | Sheet fed |

| Working area | 500mmx350mm |

| Accuracy | ±0.1mm |

| Laser type | CO2 laser |

| Laser power | 150W / 300W / 600W |

| Dimensions | 3555mm(L)x1535mm(W)x1805mm(H) |

Summary of Golden Laser’s laser die-cutting machines

|

Model No. |

Process Mode |

Working Area |

Laser Power |

|

LC120 |

Roll to Roll |

120mmx120mm |

100W / 150W / 300W |

|

LC230 |

Roll to Roll |

230mmx230mm |

100W / 150W / 300W |

|

LC250 |

Roll to Roll |

250mmx250mm |

100W / 150W / 300W |

|

LC350 |

Roll to Roll |

350mmx350mm |

150W / 300W / 600W |

|

LC800 |

Roll to Roll |

800mmx800mm |

150W / 300W / 600W |

|

LC5035 |

Sheet Fed |

500mmx350mm |

200W / 300W / 600W |

|

LC8060 |

Sheet Fed |

800mmx600mm |

200W / 300W / 600W |

| * We can design custom laser cutting systems to meet your unique needs, offering more options and flexibility than other laser manufacturers. | |||

Sheet-fed laser die-cutting machines are suitable for the following markets

- • Labels & Stickers

- • Greeting Cards

- • Folding Cartons

- • Stationery

- • Automotive

- • Abrasive Materials

- • Membrane Switches

- • Gaskets

- • Industrial