- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Roll to Roll Laser Cutting Machine for Reflective Tape

Model No.: LC230

Introduction:

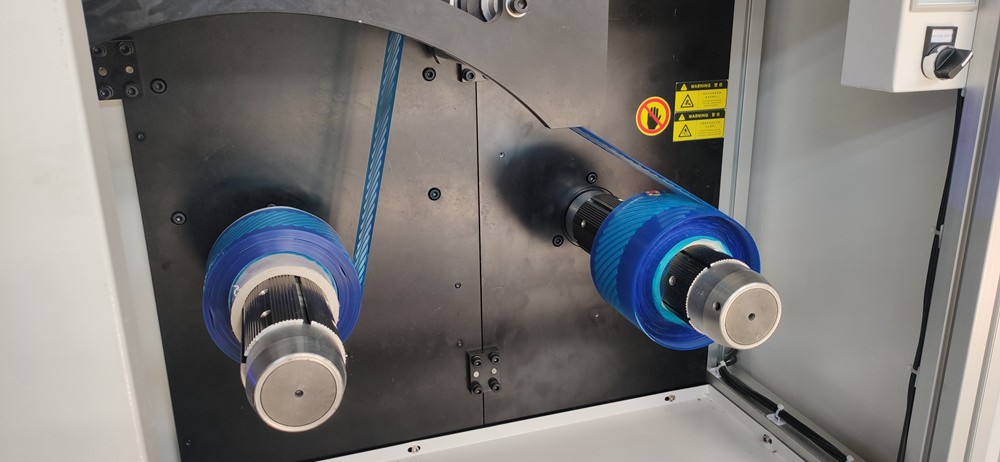

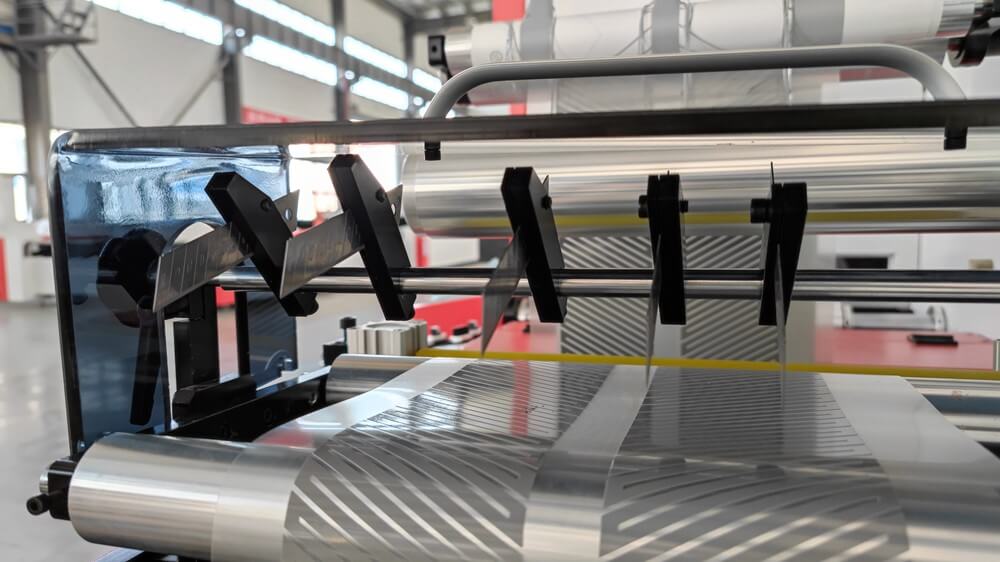

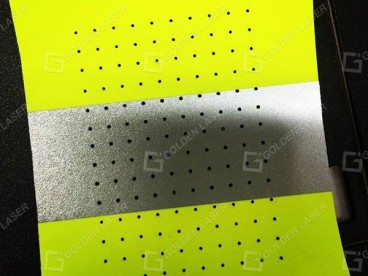

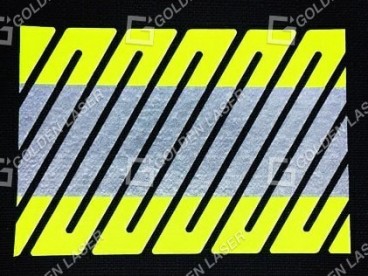

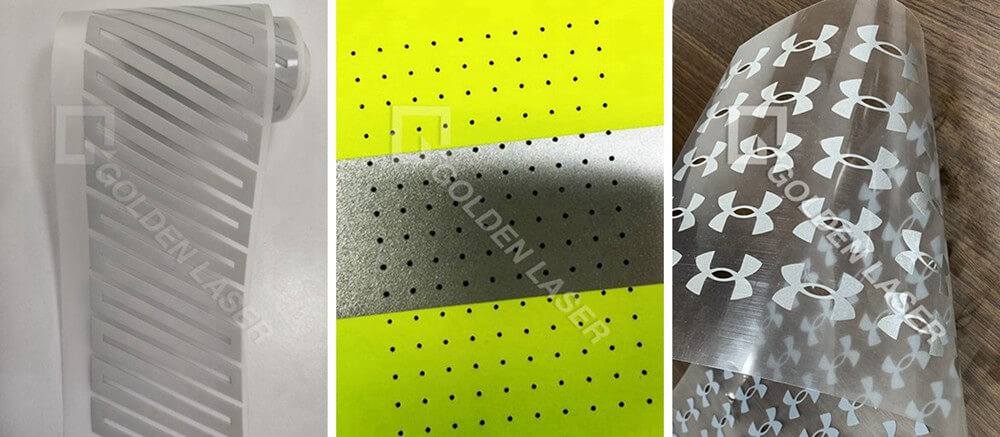

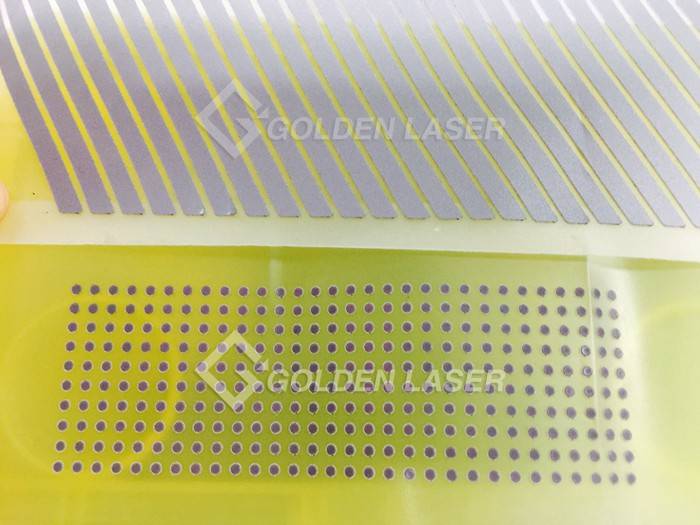

The laser finishing technology is especially effective for cutting reflective film, which cannot be cut using traditional knife cutters. LC230 laser die cutter offers a one-stop solution for unwinding, laminating, removing waste matrix, slitting and rewinding. With this reel to reel laser finishing technology, you can complete the entire finishing process on a single platform in a single pass, without using dies.

GOLDEN LASER LC230 Digital Laser Die Cutter, from roll to roll, (or roll to sheet), is a fully automated workflow.

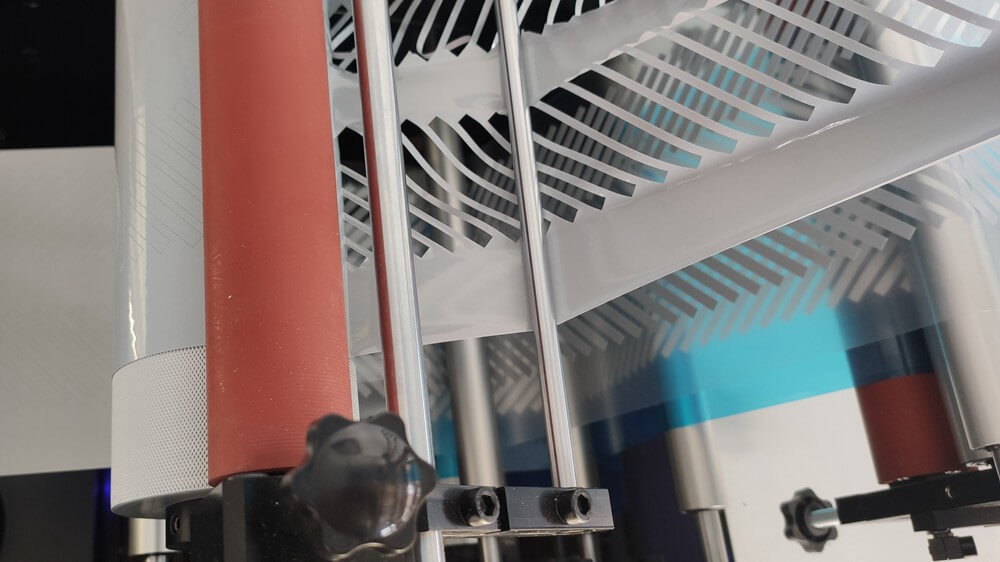

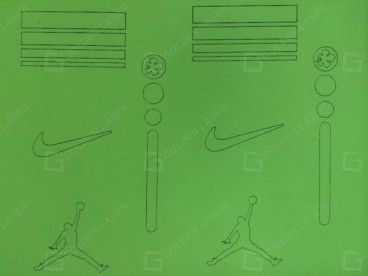

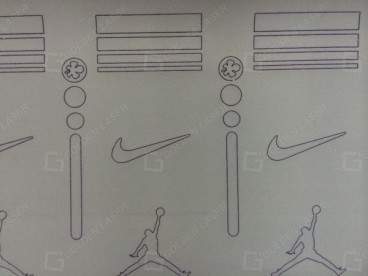

Capable of unwinding, film peeling, self-wound lamination, half-cutting (kiss-cutting), full-cutting as well as perforation, removal of waste substrate, slitting for rewinding in rolls. All these applications made in one passage in the machine with an easy and quick set-up.

It can be equipped with other options according to customer’s requirements. For example, add a guillotine option to cut transversely to create sheets.

LC230 has an encoder for feedback on the position of printed or pre-die-cut material.

The machine can work in continuous from 0 to 60 meters per minute, in flying cut mode.

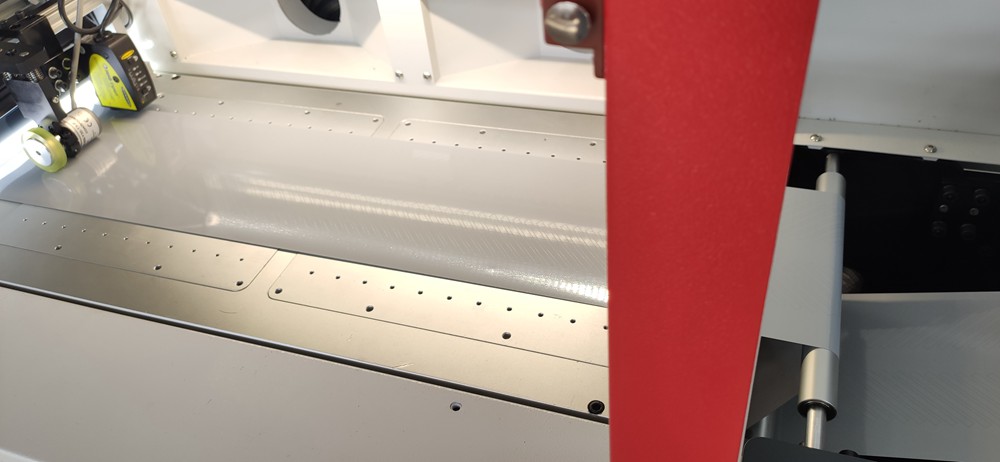

Overall View of LC230 Laser Die Cutter

Discover more detailed profiles of LC230

Golden Laser System Benefits

Laser Cutting Technology

Ideal solution for just-in-time manufacturing, short runs & complex geometry. Eliminates traditional hard tooling & die fabrication, maintenance and storage.

Rapid Processing Speeds

Full cut (total cut), half cut (kiss-cut), perforate, engrave-mark & score cut the web in continuous flying cut version.

Precision Cutting

Produce complex geometry not achieveable with rotary die cutting tools. Superior part quality that cannot be replicated in the traditional die cutting process.

PC Workstation & Software

Through the PC Workstation you can manage all the parameters of the laser station, optimize layout for maximum web speed & yields, convert graphics files to be cut & reload jobs and all parameters in seconds.

Modularity and Flexibility

Modular Design. A variety of options are available to automate and customize the system to suit a wide variety of converting requirements. Most options can be added in the future.

Vision System

Allows precision cutting of improperly positioned materials with cut-print registration of ±0.1mm. Vision (registration) systems are available for registering printed materials or pre-die cut shapes.

Encoder Control

Encoder to control the exact feeding, speed & positioning of the material.

Variety of Power & Work Areas

Wide variety of laser powers available from 100-600 Watts and work areas from 230mm x 230mm, up to 350mm x 550mm

Low Operating Costs

High through-put, elimination of hard tooling & improved material yields equal increased profit margins.

Specifications of LC230 Laser Die Cutter

| Model No. | LC230 |

| Max Web Width | 230mm / 9” |

| Max Width of Feeding | 240mm / 9.4" |

| Max Web Diameter | 400mm / 15.7” |

| Max Web Speed | 60m/min (depending on laser power, material and cut pattern) |

| Laser Source | CO2 RF laser |

| Laser Power | 100W / 150W / 300W |

| Accuracy | ±0.1mm |

| Power Supply | 380V 50Hz / 60Hz, Three phase |