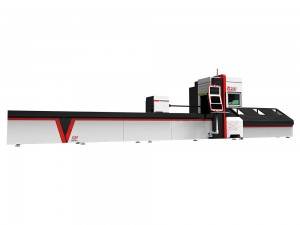

Round Tube Fiber Laser Cutting Machine

Model No.: P120

Introduction:

P120 is a specialty fiber laser cutting machine for round tube (round pipe). It is specially designed to replace the sawing machine in the motor parts industry, pipe fitting industry, etc.

- With multiple cutting processes – cutting off, beveled cutting and punching.

- Automatic loading of round pipes, saving labor and time.

- With automatic slag removal function, improving the surface quality of the workpieces.

- High processing efficiency, 3 times that of the sawing machine.

Specifications

P120 Main Technical Parameter - Take a 1500 watt laser generator as an example

10-120mm

Diameter range

0.5-10mm

Thickness range

100mm/min

Moving speed

≤40mm

Waste length

±0.1mm

Positioning accuracy

600Kg

Bundle loading

Features

Features of the P120 Round Pipe Laser Cutting Machine

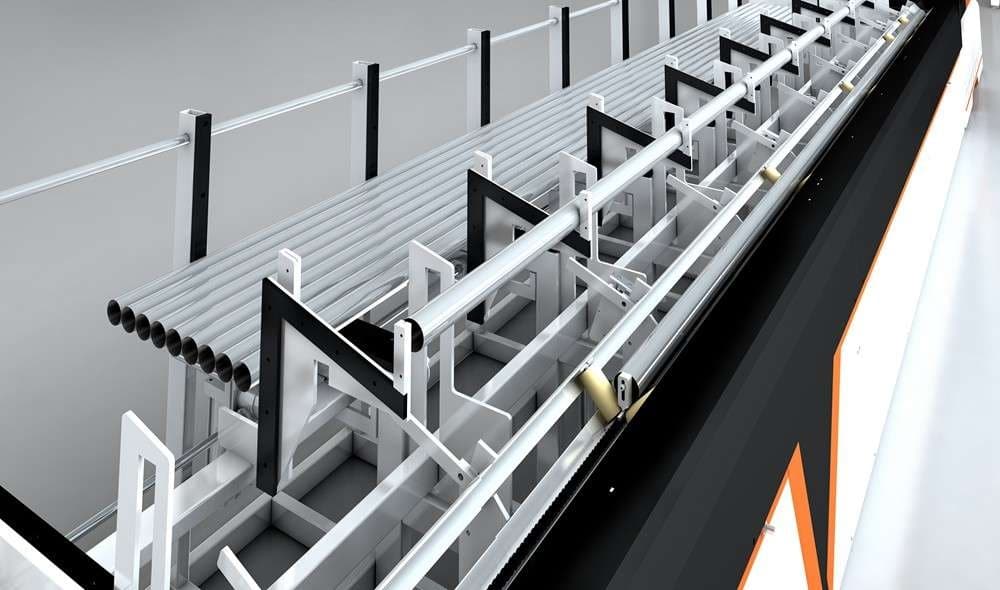

1. Round Pipe Automatic Loading

- Saving labor and improving process efficiency.

P120 round tube fiber laser cutting machine is divided into two parts: laser cutting and intelligent feeding.

After the metal pipes are simply arranged, they enter into the feeding part. The system automatically and continuously loading pipes during laser cutting, and automatically recognizes the material head between the two raw materials and cuts them.

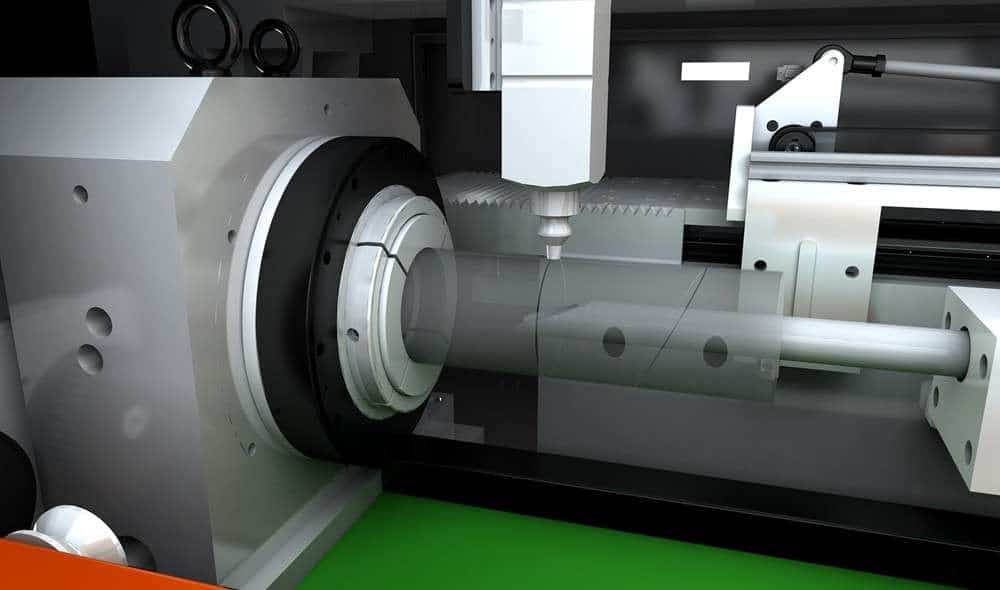

2. Fast cutting speed, multiple functions (Slag Remove Optional)

- With multiple cutting processes.

The four-axis control system can meet various graphics cutting requirements on the market. The X, Y, and Z axes can simultaneously control the trajectory of the laser head. During continuous cutting, the system can complete multiple cutting actions, saving feeding time, and improving production efficiency.

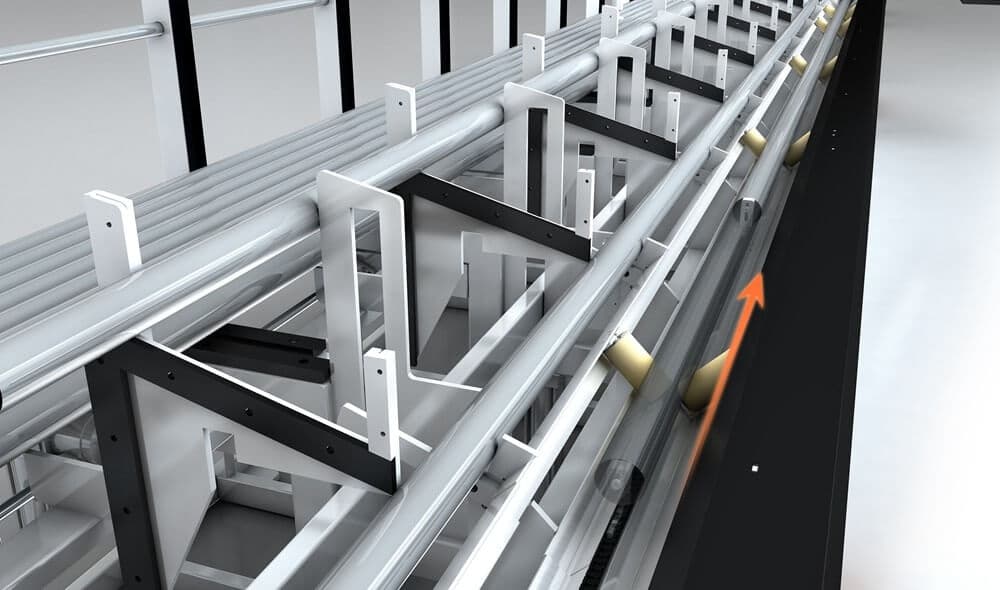

3. Less wasted pipes

- Saving material and simplify process.

When the pipe cannot be fed at one time, the subsequent pipes will continue to promote the current pipe feeding and continue to complete the tailing cutting. The normal wasted pipe length of the machine is ≤40mm, which is far lower than the ordinary laser cutting machine which the wasted pipe length is 200mm - 320mm. Less material loss, eliminating the need for wasted pipe processing.

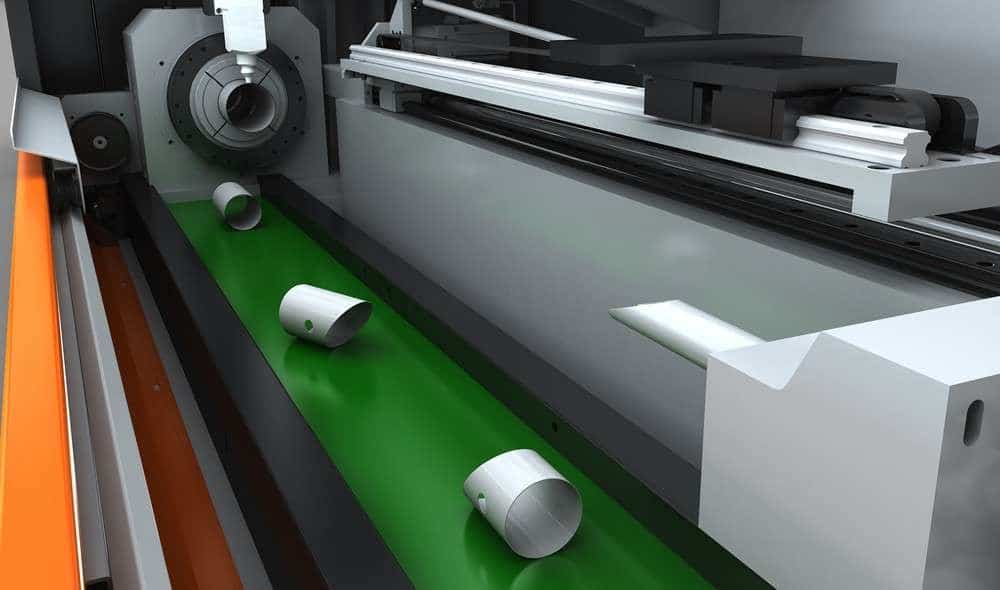

4. Automatic unloading

- Conveyor Belt Easy to Collect the Finished Pipe.

The unloading part of the machine adopts conveyor belt. The conveyor belt can ensure that the cut pipe is not scratched and the cutting effect is guaranteed.

The cut round tube will be transferred by conveyor belt and dropped into a collection box according to customer's needs.

Technical Parameter

| Model | P120 |

| Tube length | 6000mm |

| Tube diameter | 20-120mm |

| Bundle size | 800mm × 400mm × 6000mm |

| Laser source | Fiber laser resonator |

| Laser source power | 700W 1000W 1500W 2000W 2500W 3000W |

| Maximum rotate speed | 90r/min |

| Repeat position accuracy | ±0.03mm |

| Maximum position speed | 60m/min |

| Acceleration | 0.8g |

| Cutting speed | Depend on material, laser source power |

| Electric power supply | AC380V 50/60Hz |

GOLDEN LASER – FIBER LASER CUTTING SYSTEMS SERIES

|

Model NO. |

P2060A |

P3080A |

|

Pipe Length |

6m |

8m |

|

Pipe Diameter |

20mm-200mm |

20mm-300mm |

|

Laser Power |

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

|

|

Model NO. |

P2060 |

P3080 |

|

Pipe Length |

6m |

8m |

|

Pipe Diameter |

20mm-200mm |

20mm-300mm |

|

Laser Power |

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

|

|

Model NO. |

P30120 |

|

Pipe Length |

12mm |

|

Pipe Diameter |

30mm-300mm |

|

Laser Power |

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

|

Model NO. |

Laser Power |

Cutting Area |

|

GF-1530 |

700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W |

1500mm×3000mm |

|

GF-1560 |

1500mm×6000mm |

|

|

GF-2040 |

2000mm×4000mm |

|

|

GF-2060 |

2000mm×6000mm |

|

|

Model NO. |

Laser Power |

Cutting Area |

|

GF-6060 |

700W / 1000W / 1200W / 1500W |

600mm×600mm |

Application Materials

Round tubes made of stainless steel, carbon steel, aluminum, copper, etc.

Application Industry

Auto parts, elbow connectors, metal bathroom, stainless steel daily necessities, metal baby strollers, etc.

Motorcycle parts industry: Can be integrated into automated production lines: highly automated production methods, so the equipment is also integrated into the processing automobile production line.

Elbow connector industry: Not afraid of the large number and types: simple operation mode, in line with multiple batches and multiple types of elbow connector production and processing tasks, fast and free switching.

Metal sanitary ware industry: The quality of both inside and outside of the tube is in line with the demand for higher-end products: fiber laser cutting tube has no damage to the surface of the tube, and the inside of the tube can be protected by automatic slag removal. The processed metal sanitary fittings will fit the high quality of future high-end sanitary products Claim.

Stair handrails and door industries: Low-cost, value-added and low-profit industries: Compared with traditional processing methods, the use of a special fiber laser tube cutting machine for round tubes has lower cost and higher processing efficiency, and the same product can obtain higher profits.

Metal stroller industry: More extensive application capabilities: the ability of the oblique cutting process can well solve the processing requirements of the splicing end between the metal stroller round pipe workpieces.

Please contact goldenlaser for more specification and quotation about fiber laser cutting machine. Your response of following questions will help us recommend the most suitable machine.

1. What type of metal do you need to cut? Metal sheet or tube? Carbon steel or stainless steel or aluminum or galvanized steel or brass or copper …?

2. If cutting sheet metal, what is the thickness? What working area do you need? If cutting tube, what is shape, wall thickness, diameter and length of the tube?

3. What is your finished product? What is your application industry?

4. Your name, company name, email, telephone (WhatsApp) and website?