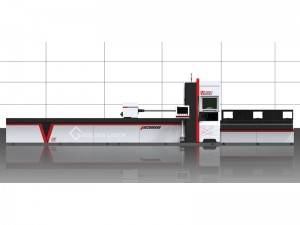

Round Tube Fiber Laser Cutting Machine

Nomoro ea mohlala: P120

Selelekela:

P120 ke mochine o khethehileng oa ho itšeha ka laser bakeng sa tube e chitja (peipi e chitja). E etselitsoe ka ho khetheha ho nkela mochini oa sawing sebaka indastering ea likarolo tsa makoloi, indasteri ea ho lokisa liphaephe, jj.

- Ka mekhoa e mengata ea ho itšeha - ho khaola, ho itšeha ka beveled le ho phunya.

- Ho kenya lipeipi tse pota-potileng, ho boloka mosebetsi le nako.

- Ka ts'ebetso ea ho tlosa slag ka boiketsetso, ho ntlafatsa boleng ba holim'a li-workpieces.

- Ts'ebetso e phahameng ea ts'ebetso, makhetlo a 3 ho feta mochini o sahang.

Litlhaloso

P120 Main Technical Parameter - Nka jenereithara ea laser ea 1500 watt e le mohlala

10-120 limilimithara

Sebaka sa bophara

0.5-10 limilimithara

Botenya bo fapaneng

100mm/min

Lebelo le tsamayang

≤40mm

Bolelele ba litšila

±0.1mm

Ho beha ho nepahala

600Kg

Bundle loading

Likaroloana

Likarolo tsa Mochini oa P120 Round Pipe Laser Cutting Machine

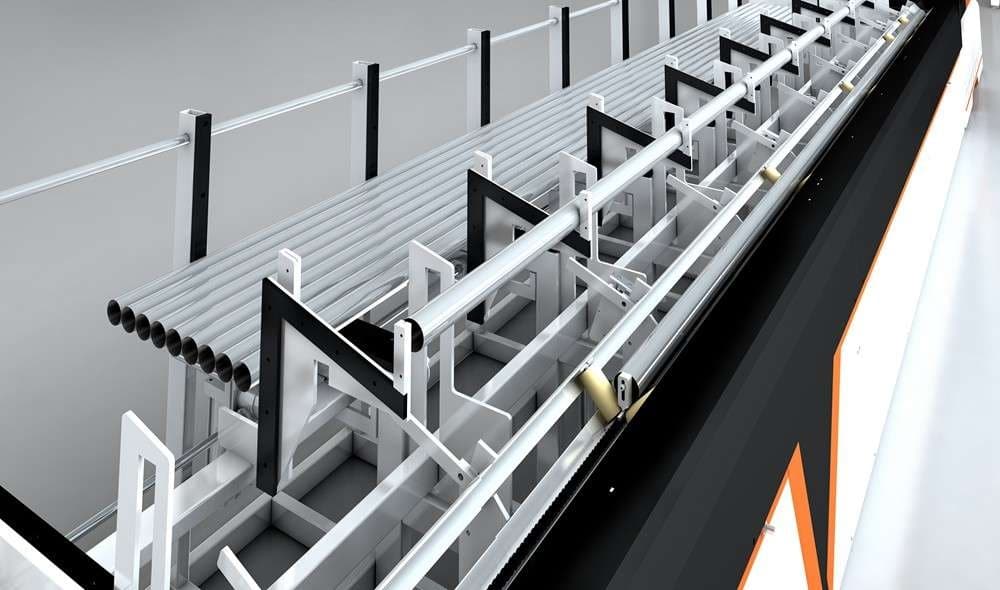

1. Round Pipe Automatic Loading

- Ho boloka mosebetsi le ho ntlafatsa katleho ea ts'ebetso.

P120 round tube fiber laser cutting e arotsoe likarolo tse peli:laser ho itšehaleho fepa ka bohlale.

Ka mor'a hore liphaephe tsa tšepe li hlophisoe feela, li kena karolong ea ho fepa. Sistimi ka tsela e iketsang le ka ho tsoelang pele laela liphaephe nakong laser itšeha, 'me ka tsela e iketsang hlokomela hlooho ea lintho tse bonahalang pakeng tsa lisebelisoa tse peli tse tala le seha bona.

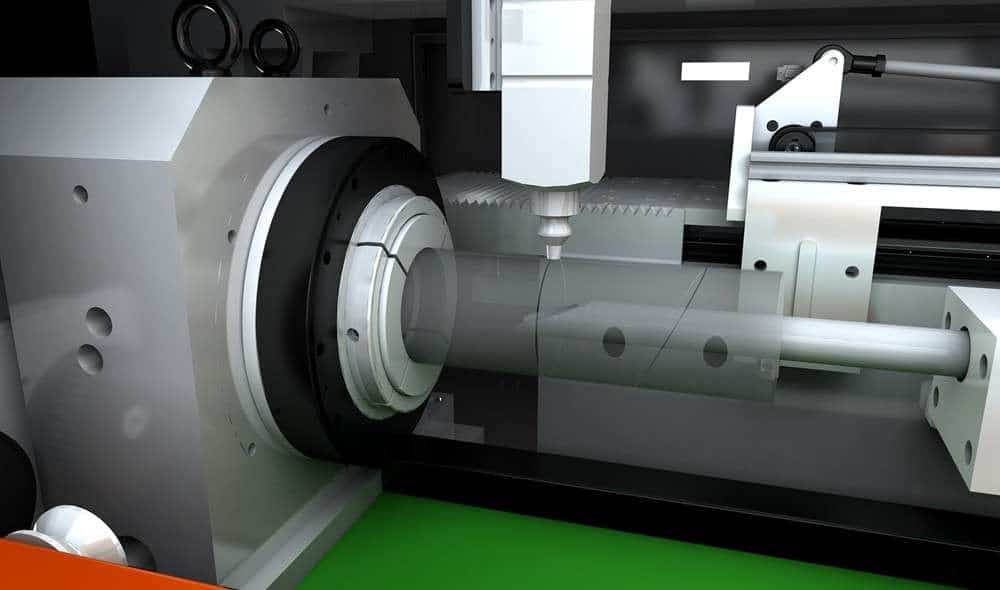

2. Lebelo la ho itšeha ka potlako, mesebetsi e mengata(Ho Ikhethela Tlosa Slag)

- Ka mekhoa e mengata ea ho itšeha.

Sistimi ea taolo ea li-axis tse 'ne e ka fihlela litlhoko tse fapaneng tsa ho seha litšoantšo 'marakeng. Lilepe tsa X, Y, le Z ka nako e le 'ngoe li khona ho laola tsela ea hlooho ea laser. Nakong ea ho itšeha ho sa khaotseng, sistimi e ka phethela liketso tse ngata tsa ho itšeha, ho boloka nako ea ho fepa, le ho ntlafatsa katleho ea tlhahiso.

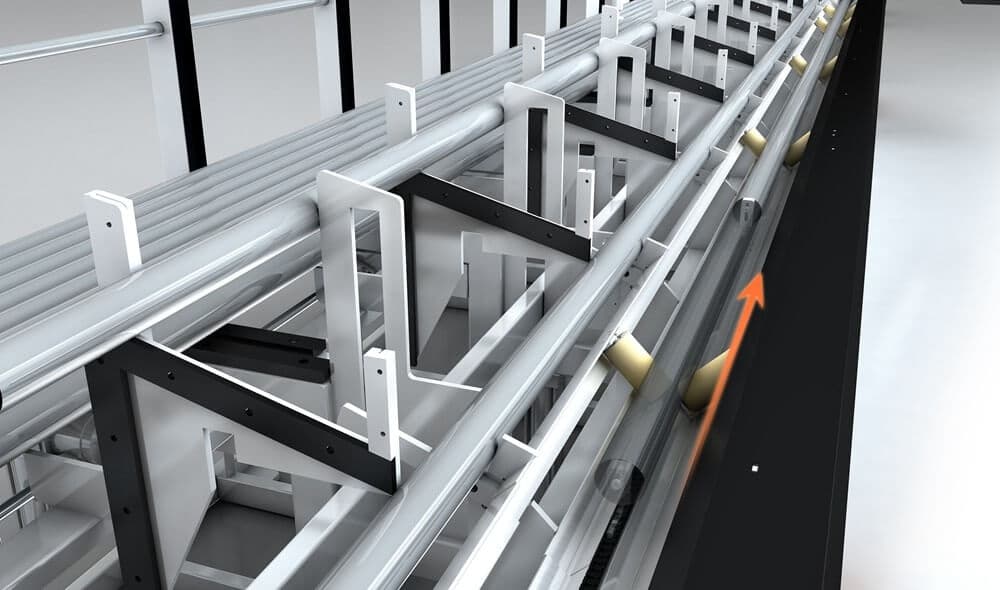

3. Liphaephe tse fokolang tse senyehileng

- Ho boloka thepa le ho nolofatsa ts'ebetso.

Ha phala e ke ke ea feptjoa ka nako e le 'ngoe, liphaephe tse latelang li tla tsoela pele ho khothalletsa phepelo ea liphaephe tsa hona joale le ho tsoela pele ho qeta ho khaola mohatla.Bolelele bo tloaelehileng ba phala e senyehileng ea mochini ke ≤40mm, e tlase haholo ho feta mochini o tloaelehileng oa ho itšeha oa laser oo bolelele ba phala e senyehileng e leng 200mm - 320mm. Tahlehelo e nyane ea lintho tse bonahalang, ho felisa tlhoko ea ts'ebetso ea liphaephe tse senyehileng.

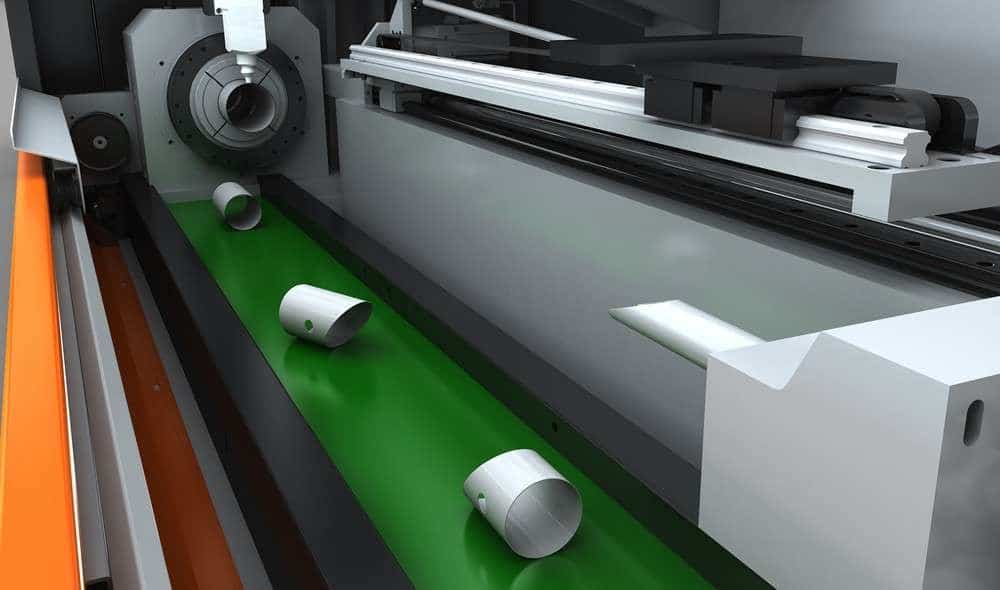

4. Ho laolla ka ho iketsa

- Conveyor Belt Ho Bonolo ho Bokella Pipe e Feliloeng.

Karolo e laollang ea mochini e nka lebanta la conveyor. Lebanta la conveyor le ka etsa bonnete ba hore phala e sehiloeng ha e hlajoe 'me phello ea ho itšeha e tiisitsoe.

Tube e chitja e sehiloeng e tla fetisoa ka lebanta la conveyor ebe e akheloa ka lebokoseng la pokello ho latela litlhoko tsa moreki.

Tekheniki Parameter

| Mohlala | P120 |

| Bolelele ba tube | 6000mm |

| Bophara ba tube | 20-120 limilimithara |

| Boholo ba bongata | 800mm × 400mm × 6000mm |

| Mohloli oa laser | Fiber laser resonator |

| Matla a mohloli oa laser | 700W 1000W 1500W 2000W 2500W 3000W |

| Lebelo le phahameng la ho potoloha | 90r/mots |

| Pheta ho nepahala ha boemo | ± 0.03 limilimithara |

| Lebelo le phahameng la boemo | 60m/min |

| Ho potlakisa | 0.8g |

| Ho poma lebelo | Itšetlehile ka thepa, matla a mohloli oa laser |

| Phepelo ea motlakase | AC380V 50/60Hz |

KHAUTA LASER - FIBER LASER seha System LEtoto

| Mohlala NO. | P2060A | P3080A |

| Bolelele ba Pipe | 6m | 8m |

| Pipe Diameter | 20mm-200mm | 20mm-300mm |

| Matla a Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W | |

| Mohlala NO. | P2060 | P3080 |

| Bolelele ba Pipe | 6m | 8m |

| Pipe Diameter | 20mm-200mm | 20mm-300mm |

| Matla a Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W | |

| Mohlala NO. | P30120 |

| Bolelele ba Pipe | 12 limilimithara |

| Pipe Diameter | 30mm-300mm |

| Matla a Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

| Mohlala NO. | Matla a Laser | Sebaka sa ho Seha |

| GF-1530 | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W | 1500mm×3000mm |

| GF-1560 | 1500mm×6000mm | |

| GF-2040 | 2000mm×4000mm | |

| GF-2060 | 2000mm×6000mm | |

| Mohlala NO. | Matla a Laser | Sebaka sa ho Seha |

| GF-6060 | 700W / 1000W / 1200W / 1500W | 600mmx600mm |

Lisebelisoa tsa Kopo

Li-tubes tse pota-potileng tse entsoeng ka tšepe e sa hloekang, tšepe ea carbon, aluminium, koporo, joalo-joalo.

Indasteri ea Kopo

Likarolo tsa likoloi, likhokahano tsa setsoe, kamore ea ho hlapela ea tšepe, lisebelisoa tsa letsatsi le letsatsi tsa tšepe e sa hloekang, likoloi tsa bana tsa tšepe, jj.

Indasteri ea likarolo tsa lithuthuthu:E ka kopanngoa le melapo ea tlhahiso e ikemetseng: mekhoa ea tlhahiso e ikemetseng haholo, kahoo thepa e boetse e kenyelelitsoe moleng oa tlhahiso ea likoloi.

Indasteri ea sehokelo sa Elbow:Ha u tšabe palo e kholo le mefuta: mokhoa o bonolo oa ts'ebetso, o lumellanang le lihlopha tse ngata le mefuta e mengata ea tlhahiso ea sehokelo sa setsoe le mesebetsi ea ts'ebetso, ho fetoha ka potlako le mahala.

Indasteri ea thepa ea tšepe ea tšepe:Boleng ba ka hare le ka ntle ho tube bo lumellana le tlhokahalo ea lihlahisoa tse phahameng: fiber laser cutting tube ha e na tšenyo e ka holim'a tube, 'me ka hare ho tube e ka sireletsoa ka ho tlosoa ha slag ka ho toba. Lisebelisoa tsa tšepe tse entsoeng ka bohloeki li tla lumellana le boleng bo phahameng ba nakong e tlang lihlahisoa tsa bohloeki tse phahameng.

Liindasteri tsa litepisi le mamati:Liindasteri tse theko e tlaase, tse eketsang boleng le phaello e tlaase: Ha li bapisoa le mekhoa e tloaelehileng ea ho sebetsa, tšebeliso ea mochine o khethehileng oa fiber laser tube cuting bakeng sa li-tubes tse pota-potileng ho na le litšenyehelo tse tlaase le tse sebetsang hantle, 'me sehlahisoa se tšoanang se ka fumana phaello e phahameng.

Indasteri ea tšepe ea tšepe:Matla a eketsehileng a kopo: bokhoni ba ts'ebetso ea ho itšeha ka oblique e ka rarolla hantle litlhoko tsa ts'ebetso ea qetello ea splicing pakeng tsa tšepe ea tšepe e pota-potileng lipeipi.

Ka kopo ikopanye le goldenlaser bakeng sa lintlha tse ling le mantsoe a qotsitsoeng mabapi le mochini oa ho itšeha oa fiber laser. Karabo ea hau lipotsong tse latelang e tla re thusa ho khothaletsa mochine o loketseng ka ho fetisisa.

1. Ke mofuta ofe oa tšepe oo u lokelang ho o khaola? Letlapa la tšepe kapa tube? Tšepe ea carbon kapa tšepe e sa hloekang kapa aluminiamo kapa tšepe e entsoeng ka masenke kapa koporo kapa koporo ...?

2. Haeba ho seha lakane tšepe, botenya ke eng? U hloka sebaka sefe sa ho sebetsa? Haeba tube ea ho itšeha, sebopeho, botenya ba lerako, bophara le bolelele ba tube ke eng?

3. Sehlahisoa sa hau se felileng ke sefe? Indasteri ea hau ea kopo ke efe?

4. Lebitso la hau, lebitso la k'hamphani, lengolo-tsoibila, mohala (WhatsApp) le sebaka sa marang-rang?