Laser Cutting Machine - Flatbed CO2 Laser Cutting Machine

Joalo ka moetsi oa mochini oa ho itšeha oa laser, Golden Laser e fana ka moralo o hlophisitsoeng, tlhahiso, phano, tšebeletso ea kamora ho rekisa le tharollo ea tekheniki.

KHAUTA LASER - Flatbed CO2Mochini oa ho itšeha ka LaserLikaroloana

I. Mochini oa ho Seha oa Laser oa Visionbakeng sa Liaparo tsa Lipapali tse Hatisitsoeng tsa Sublimation, Liaparo tsa Libaesekele, Liaparo tsa Sesepa, Libanner, Lifolakha

KHAUTA LASER - Flatbed CO2 Laser Cutting Machine

Pono ea laser ho itšeha mochine o loketseng ho seha ditsitithale khatiso masela sublimation textile tsa libopeho tsohle le boholo. Lik'hamera li hlahloba lesela, li lemoha le ho lemoha contour e hatisitsoeng, kapa li nka matšoao a ngolisoang a hatisitsoeng ebe li khaola meralo e khethiloeng ka lebelo le ho nepahala. Conveyor le auto-feeder li sebelisetsoa ho boloka ho khaola ho sa khaotseng, ho boloka nako le ho eketsa lebelo la tlhahiso.

√ Auto feeding √ Flying scan √ lebelo le phahameng √ Kelello e bohlale ya paterone ya lesela le hatisitsweng

→Skena (ho lemoha le ho elelloa) moqolo oa lesela la sublimated mme o nahanele ho honyela kapa ho sotha e ka 'nang ea etsahala nakong ea ts'ebetso ea sublimation le ho khaola ka nepo meralo leha e le efe.

●E kholo sebopeho se fofang scan.Ho bitsa metsotsoana e 5 feela ho tseba sebaka sa ho sebetsa. Ha e ntse e fepa lesela ka conveyor e tsamaeang, kh'amera ea nako ea 'nete e khona ho tseba litšoantšo tse hatisitsoeng ka potlako mme e romelle liphetho ho laser cutter. Ka mor'a ho khaola sebaka sohle sa mosebetsi, mokhoa ona o tla phetoa ntle le ho kenella ka letsoho.

●E ntle ho sebetsana le litšoantšo tse rarahaneng.Bakeng sa litšoantšo tse ntle le tse qaqileng, software e ka ntša litšoantšo tsa pele ho ea ka boemo ba lintlha tsa matšoao le ho etsa seha. Ho nepahala ha seha ho fihla ho ± 1mm.

● E ntle ho kuta lesela le otlolohileng.Moeli oa ho tiisa o iketsang. Sekhahla se hloekile, se bonolo ebile se boreleli ka ho nepahala ho phahameng.

II.Laser Cutting Machine bakeng sa seaparoKopo ea indasteri ea ho itšeha

•Bakeng sa batch e mahareng le e nyane le mefuta e fapaneng ea tlhahiso ea liaparo, haholo-holo e loketseng liaparo tse ikhethileng.

•E loketse mefuta e fapaneng ea masela a ho itšeha. Ho khaola moralo ofe kapa ofe oa litšoantšo. Likhahla tse boreleli le tse hlakileng. Tiiso e tiisitsoeng. Ha ho na moeli o chesitsoeng kapa o robehileng. E babatsehang ho itšeha boleng.

•Tafole ea ho sebetsa ea conveyor e nang le sistimi ea ho fepa ka boiketsetso (ka boikhethelo), hlokomela ho fepa le ho itšeha ka mokhoa o ikemetseng.

•Mohaho oa Y-axis habeli. Tsela ea lebone la laser e fofang. Sistimi ea makoloi ea Servo, ho itšeha ka lebelo le phahameng. Tsamaiso ena ea ho itšeha e ka etsa sehlaha se eketsehileng nako e telele le fomate e feletseng e tsoelang pele ea ho fepa le ho itšeha ka mokhoa o le mong o fetang sebaka sa ho itšeha sa mochine.

•Ts'ebetso e ikhethang ea bukana le e ikemetseng e sebetsanang le moralo, e ntlafatsa ts'ebeliso ea lisebelisoa ho isa ho tse feteletseng. E boetse e na le ho etsa lipaterone, digitizing ea lifoto, le mesebetsi ea maemo, e bonolo ebile e sebetsa.

•Mochini ona oa ho itšeha oa laser o ka ba le sistimi e kholo ea ho tsebahatsa ka boits'oaro le sistimi ea projeke bakeng sa seaparo sa motho ka nepo le ho itšeha ka bohlale.

III.Sefa Medias , Masela a Indasteri & Tekheniki Textiles Laser Cutting Kopo

Ho itšeha ka laser ho loketse haholo bakeng sa mecha ea litaba ea filthara. Ho finyella litlhoko tse khethehileng mabapi le thepa ea ho itšeha, GOLDENLASER e fana ka matla a fapaneng a laser le litharollo tse feletseng tsa ho itšeha ka laser.

●Ho nepahala ha seha ho ka fihla ho 0.1mm

●Phekolo ea mocheso, ho tiisa ka mokhoa o itekanetseng ka mokhoa o boreleli

●E fumaneha ho beha nako ea tšebeliso ea lesela ho latela tlhoko ea mosebelisi.

●Tšoaea pene le laser switching automatic, phethela tšebetso eohle ea ho phunya, ho tšoaea le ho seha ka mohato o le mong.

●Moralo o bohlale oa lits'oants'o le software ea ho haha sehlaha, ts'ebetso e bonolo, e fumanehang bakeng sa ho seha libopeho life kapa life.

●Tafole e sebetsang ea vacuum adsorption, ka ho phethahetseng rarolla bothata ba masela a phunyang.

●Lebanta la conveyor la tšepe e sa hloekang, le nang le lisebelisoa tse tsoelang pele tsa ho fepa le ho bokella, ts'ebetso e phahameng.

●Sebopeho se koaletsoeng ka ho feletseng ho netefatsa hore lerōle le sehang ha le lutle, le loketse ho sebetsa limela tsa tlhahiso e matla.

IV.Letlalo Nesting le Laser Cutting Systembakeng sa Sekoaelo sa Setulo sa Koloi, Mekotla, Lieta

Sephutheloana sa Sistimi ea ho Seha Letlalo -Sephutheloana sa Leather Nesting se nang le li-module tse latelang:Mehlala / Litaelo tsa Letlalo, Nesting e Tloaelehileng, Leather Digitizing le Leather CUT & Collect.

Melemo

•Ts'ebetso ea laser e bonolo ebile e bonolo. Kamora ho seta mohlala, laser e ka qala ho sebetsa.

•Maqhutsu a boreleli. Ha ho khatello ea mochine, ha ho na deformation. Ha ho na hlobo e hlokahalang. Ts'ebetso ea laser e ka boloka litšenyehelo tsa tlhahiso ea hlobo le nako ea ho itokisetsa.•Boleng bo botle ba ho itšeha. Ho khaola ho nepahetseng ho ka fihla ho 0.1mm. Ntle le lithibelo tsa litšoantšo.

Likarolo tsa Mochini

•Haholo-holo e loketseng ho itšeha letlalo la 'nete.

•Ke sete e felletseng le e sebetsang ea sistimi ea 'nete ea laser ea letlalo, e nang le paterone digitizing, sistimi e hlokomelang le software ea ho etsa sehlaha. Tekanyo e phahameng ea boiketsetso, ho ntlafatsa ts'ebetso le ho boloka thepa.

•E sebelisa sistimi e nepahetseng haholo ea ho bala e khonang ho bala ka nepo sebopeho sa letlalo le ho qoba sebaka se futsanehileng le ho etsa sehlaha sa othomathike ka potlako likotong tsa sampole (basebelisi le bona ba ka sebelisa sehlaha ka letsoho).

Nolofatsa ts'ebetso e rarahaneng ea ho itšeha ha 'nete ea letlalo ho isa mehatong e mene

| Ho hlahloba letlalo | Ho Bala Letlalo | Nesting | Ho poma |

V. Thepa ea ka tlung, Upholstery Textile, Sofa, Mattress Laser Cutting Kopo

●E sebelisoa ho sofa, materase, likharetene, pillowcase ea masela a thepa ea ka tlung le indasteri ea masela ea upholstery. Ho khaola masela a fapaneng, joalo ka lesela le otlolohileng, polyester, letlalo, PU, k'hothone, silika, lihlahisoa tse boreleli, foam, PVC le lisebelisoa tse kopaneng, jj.

●Sete e felletseng ea litharollo tsa ho itšeha ka laser. Ho fana ka digitizing, moralo oa sampole, ho etsa matšoao, litharollo tse tsoelang pele tsa ho itšeha le ho bokella. Mochini o felletseng oa ho itšeha oa dijithale o ka nka sebaka sa mokhoa o tloaelehileng oa ho sebetsa.

●Ho boloka lintho tse bonahalang. Software e etsang matshwao e bonolo ho e sebetsa, ho etsa matshwao ka boiketsetso. 15 ~ 20% thepa e ka bolokeha. Ha ho hlokahale basebetsi ba etsang li-marker.

●Ho fokotsa mosebetsi. Ho tloha ho moralo ho isa ho ho itšeha, ho hlokahala feela opareitara e le 'ngoe ho sebelisa mochini oa ho itšeha, ho boloka litšenyehelo tsa basebetsi.

●Ho itšeha ka laser, ho nepahala ho phahameng, ho itšeha ka mokhoa o phethahetseng, le ho itšeha ka laser ho ka fihlela moralo oa boqapi. Ts'ebetso eo e seng ea khokahanyo. Sebaka sa laser se fihla ho 0.1mm. E sebetsana le litšoantšo tse khutlonnetsepa, tse se nang letho le tse ling tse rarahaneng.

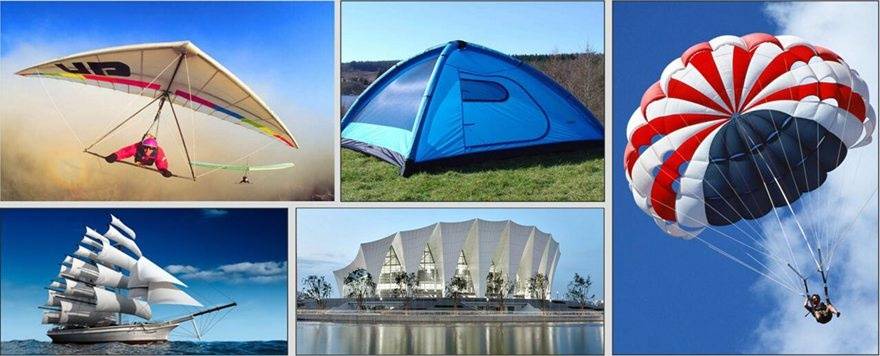

VI. Parachute, Paraglider, Sailcloth, Tente Laser Cutting Kopo

● Sebopeho sa mookoli se nang le tokelo ea molao, se ikhethile bakeng sa sebopeho se pharaletseng.

● E etselitsoe ho seha liboto tsa liphatlalatso tsa ka ntle, parachute, paraglider, litente, lesela la ho sesa, lihlahisoa tse bululehang. E loketse ho seha PVC, ETFE, PTFE, PE, lesela la k'hothone, lesela la Oxford, nylon, nonwoven, PU kapa AC coating material, joalo-joalo.

● Boiketsetso. Sistimi ea ho fepa ka boiketsetso, mabanta a conveyor le ho bokella tafole ea tšebetso.

● Ho itšeha nako e telele ho sa khaotse. E khona ho seha litšoantšo tse 20m, 40m kapa le ho feta.

● Ho boloka mosebetsi. Ho tloha ho moralo ho isa ho ho itšeha, ho hloka motho a le mong feela ho sebetsa.

● Ho boloka boitsebiso. Software e bonolo ea ho sebelisa Marker, e bolokang 7% kapa lisebelisoa ho feta.

● Nolofatsa mokhoa oo. Tšebeliso e ngata bakeng sa mochini o le mong: ho seha masela ho tloha moqolong ho ea ho likotoana, ho tšoaea palo likotong, le ho cheka, joalo-joalo.

● Ka letoto lena la mechine ea laser ho finyella ply e le 'ngoe kapa ho itšeha ka makhetlo a mangata ho sebelisitsoe ka katleho tlhahiso ea boima.

| KHAUTA LASER - CO2 Flatbed Laser Cutting Machine Configuration | ||

| Sebaka sa ho Seha(amohela ho itlhophisa) |

|

|

| Tafole ea Mosebetsi | Tafole e sebetsang ea adsorption conveyor | |

| Mofuta oa Laser | CO2 DC khalase laser tube / CO2 RF tšepe laser tube | |

| Matla a Laser | 80W ~ 500W | |

| Software | GOLDENLASER Software Cutting, CAD Pattern Designer, Auto Marker, Marker software, Leather Digitizing system, VisionCUT, sampole board photo digitizer system | |

| Ka ho Fetisisa | Gear feeder (boikhethelo), Lokisa mokhoa oa ho fepa o khelohileng (ho ikhethela) | |

| Taba ea boikhethelo | Sebaka sa lebone le lefubelu (ka boikhethelo), Tšoaea pene (ho ikhethela) | |