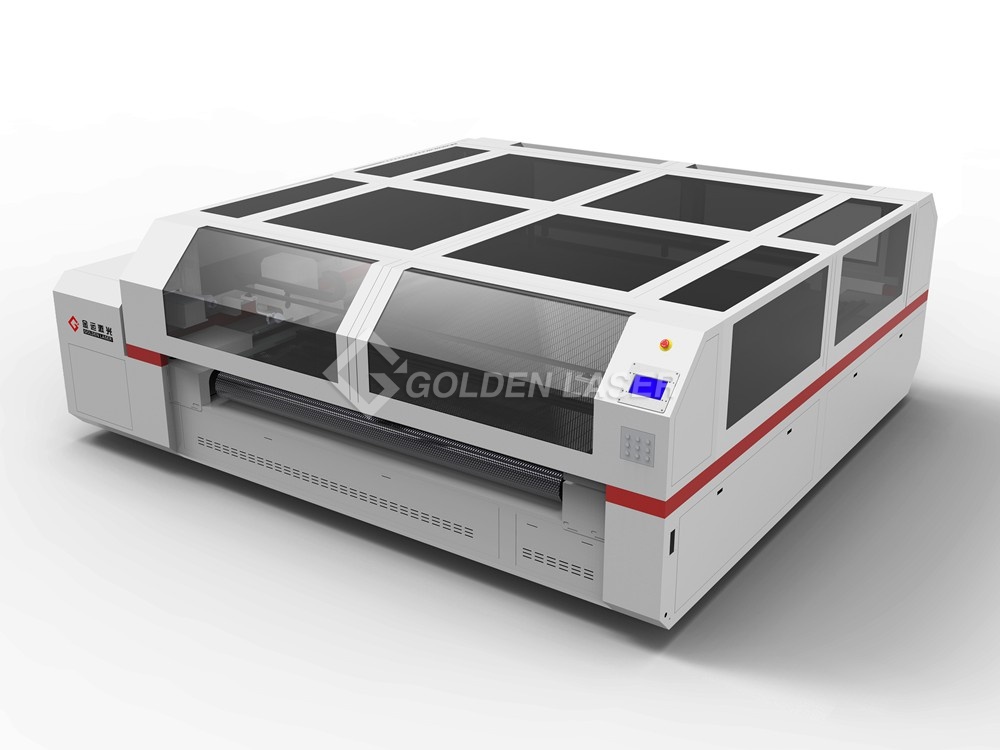

Textile Laser Cutting Machine with Auto Feeder and Conveyor Mesh Belt

Model No.: JMCCJG-160300LD

Introduction:

JMC Series Laser Cutter is our large format laser cutting system which is driven by gear and rack with servo motor control. With more than 15 years production experience about this series of CO2 flatbed laser cutting machine, it provides optional extras and software to simplify your production and increase your possibilities.

Technical Specifications of Laser Cutting Machine

Durable CO2 laser cutting system with high speed and high precision

| Laser type | CO2 laser |

| Laser power | 150w, 300w, 600w, 800w |

| Working area (W x L) | 1600mm x 3000mm (63” x 118”) |

| Max. material width | 1600mm (63”) |

| Working table | Vacuum conveyor table |

| Cutting speed | 0-1,200mm/s |

| Acceleration | 8,000mm/s2 |

| Repositioning accuracy | ≤0.05mm |

| Motion system | Servo motor, Gear and rack driven |

| Power supply | AC220V±5% 50/60Hz |

| Format supported | PLT, DXF, AI, DST, BMP |

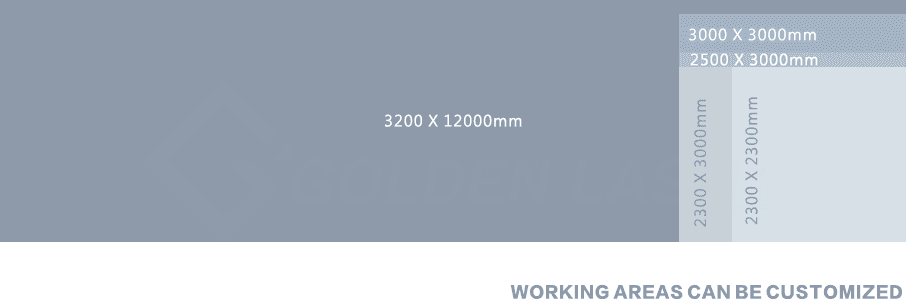

※ Working areas can be customized on request. A variety of processing areas tailored to your applications are available.

What are the benefits of cutting textile with laser equipment by goldenlaser?

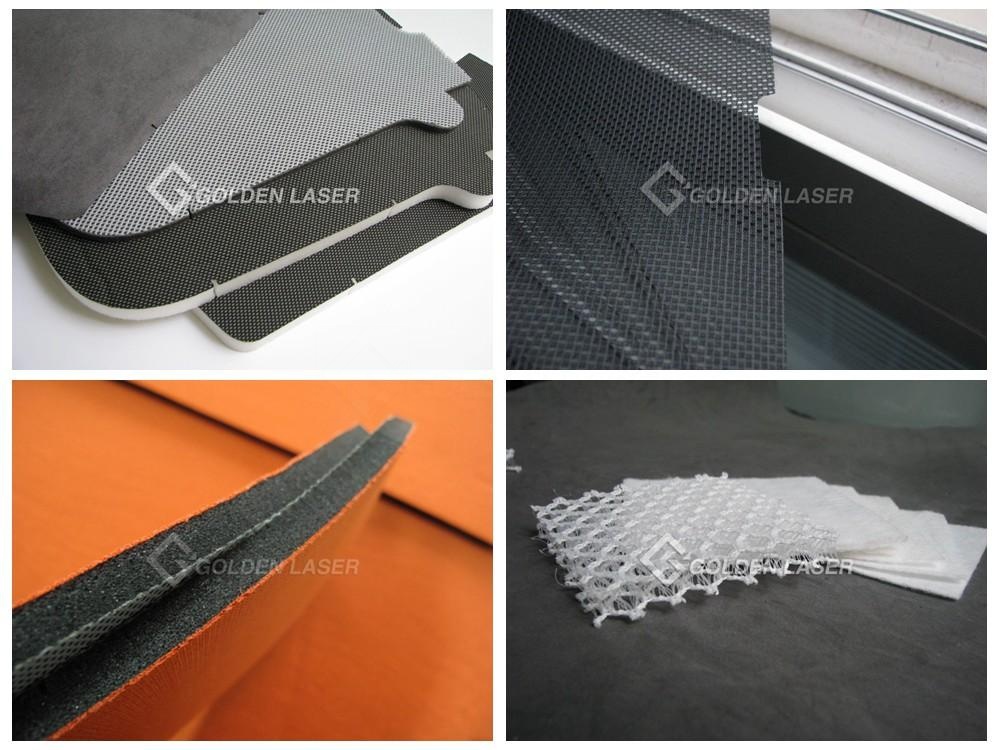

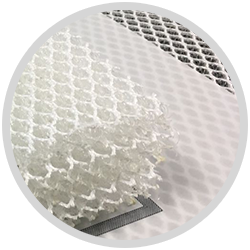

Laser cutting 3D mesh textile

Capable of cutting mesh fabrics without burnt edges for the field of automotive interiors and technical textile industry.

Clean and smooth edges

During the laser cutting (especially with synthetic fabric), cutting edge gets sealed and no additional work is required.

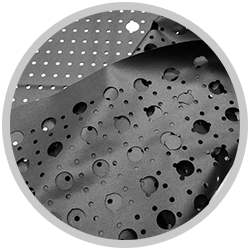

Cutting holes and intricate designs

Laser is able to cut absolutely incredibly complicated internal shapes, even cut extremely small holes (laser perforation).

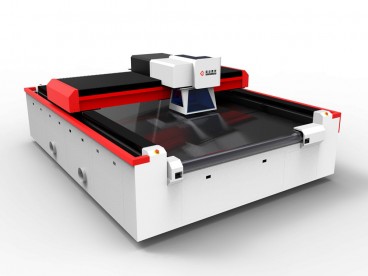

Features of JMC Series Cutting Laser Machine

Automatic textile cutting solution with laser cutting systems of goldenlaser

1. High-speed cutting

Rack and pinion motion system equipped with high-power CO2 laser tube, reaches up to 1200 mm/s cutting speed, 8000 mm/s2 acceleration speed.

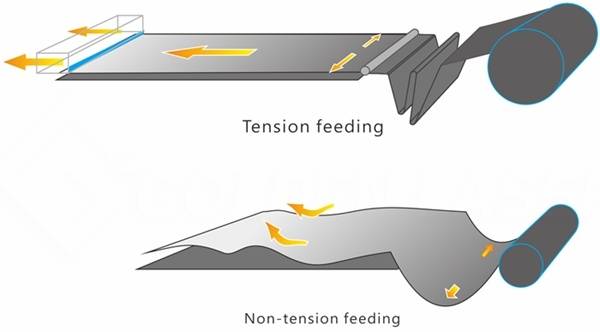

2. Precision tension feeding

No tension feeder will easy to distort the variant in the feeding process, resulting the ordinary correction function multiplier.

Tension feeder in a comprehensive fixed on both sides of the material at the same time, with automatically pull the cloth delivery by roller, all process with tension, it will be perfect correction and feeding precision.

3. Automatic sorting system

- Fully automatic sorting system. Make the feeding, cutting and sorting of materials at one go.

- Increase the processing quality. Automated unloading of the completed cut parts.

- Increased level of automation during the unloading and sorting process also accelerates your subsequent manufacturing processes.

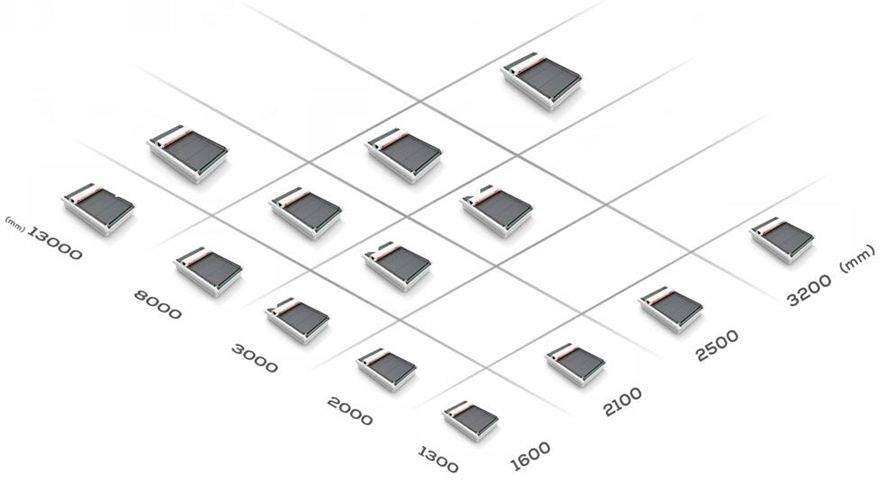

4. Working areas can be customized

2300mm×2300mm (90.5 inch×90.5 inch), 2500mm×3000mm (98.4in×118in), 3000mm×3000mm (118in×118in), Or optional. The largest working area is up to 3200mm×12000mm (126in×472.4in)

Optimize your workflow with the options:

Customized optional extras simplify your production and increase your possibilities

Nesting Software

Automated Software to make your workflow even more efficient

Goldenlaser’s Auto Maker Software will help to deliver fast with uncompromised quality. With the help of our nesting software, your cutting files will perfectly be placed on the material. You will optimize the exploitation of your area and minimize your material consumption with the powerful nesting module.

Technical Parameter

| Laser type | CO2 laser |

| Laser power | 150w, 300w, 600w, 800w |

| Working area (W × L) | 1600mm×3000mm (63”×118”) |

| Max. material width | 1600mm (63”) |

| Working table | Vacuum conveyor working table |

| Cutting speed | 0 ~ 1200mm/s |

| Acceleration | 8000mm/s2 |

| Repositioning accuracy | ≤0.05mm |

| Motion system | Servo motor, Gear and rack driven |

| Power supply | AC220V±5% 50/60Hz |

| Graphics format supported | PLT, DXF, AI, DST, BMP |

※ Working areas can be customized as per requirement.

GOLDENLASER – JMC SERIES HIGH SPEED HIGH PRECISION CO2 LASER CUTTERS

Working areas: 1600mm×2000mm (63″×79″), 1600mm×3000mm (63″×118″), 2300mm×2300mm (90.5″×90.5″), 2500mm×3000mm (98.4″×118″), 3000mm×3000mm (118″×118″), 3500mm×4000mm (137.7″×157.4″) …

***The cutting bed sizes can be customized according to different applications.***

Applicable Materials

Polyester (PES), viscose, cotton, nylon, nonwoven and woven fabrics, synthetic fibers, polypropylene (PP), knitted fabrics, felts, polyamide (PA), glass fiber (or glass fibre, fiberglass, fibreglass), mesh, Lycra, Kevlar, aramid, polyester PET, PTFE, paper, foam, plastic, etc.

Applications

1. Clothing Textiles: technical textiles for clothing applications.

2. Home Textiles: carpets, mattress, sofas, curtains, cushion materials, pillows, floor and wall coverings, textile wallpaper, etc.

3. Industrial Textiles: filtration, air dispersion ducts, etc.

4. Textiles used in automotive and aerospace: aircraft carpets, cat mats, seat covers, seat belts, airbags, etc.

5. Outdoors and Sports textiles: sports equipment, flying and sailing sports, canvas covers, marquee tents, parachutes, paragliding, kitesurf, boats (inflatable), air balloons, etc.

6. Protective textiles: insulation materials, bulletproof vests, etc.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?