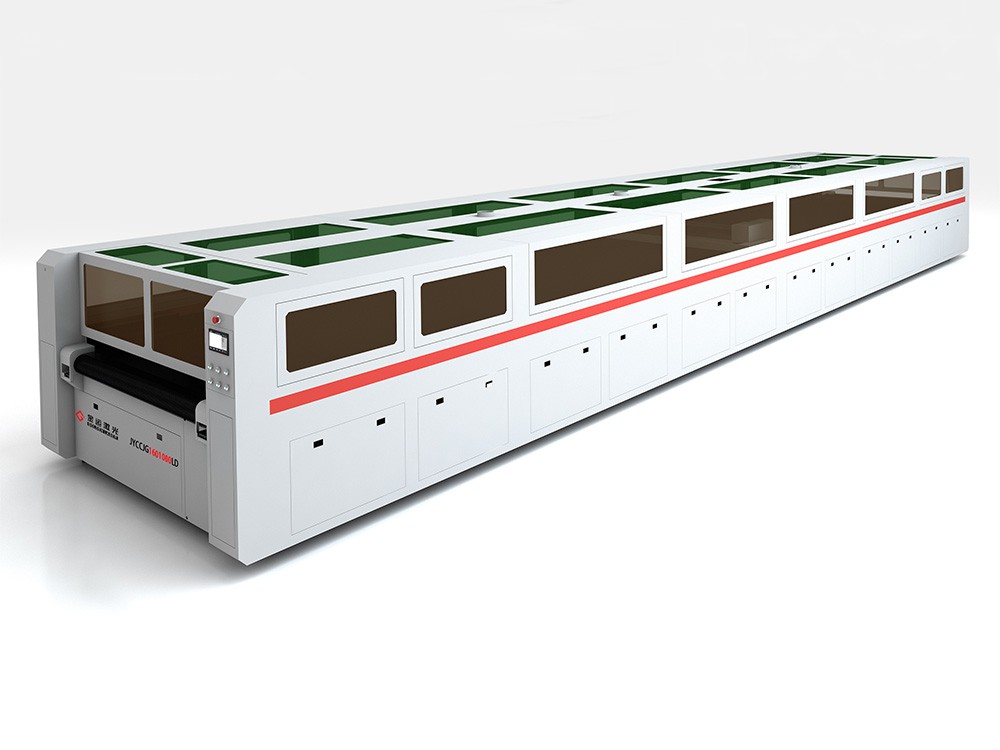

Ultra-long Table Size Laser Cutting Machine

The cutting table width of this CO2 flatbed laser cutting machine is 1.6m ( or 2.1m, 2.5m), and the table length is 6 meter, 10 meter and even 11 meter and 13 meter long.

With the ultra-long table, you can cut extra-long patterns with one shot, no need to cut half of the patterns and then process the rest of the materials. Hence, there is no sewing gap on the cut piece that the laser cutter creates. The Ultra-long Table Design processes the materials precisely and efficiently with little feeding time.

Main Technical Parameter of the CO2 Laser Cutter Machine with Extra-Long Cutting Bed

| Laser type: |

CO2 glass laser / CO2 RF metal laser |

| Laser power: |

150W, 300W |

| Working area: |

1,600mm(W) x 10,000mm (L) |

| Working table: |

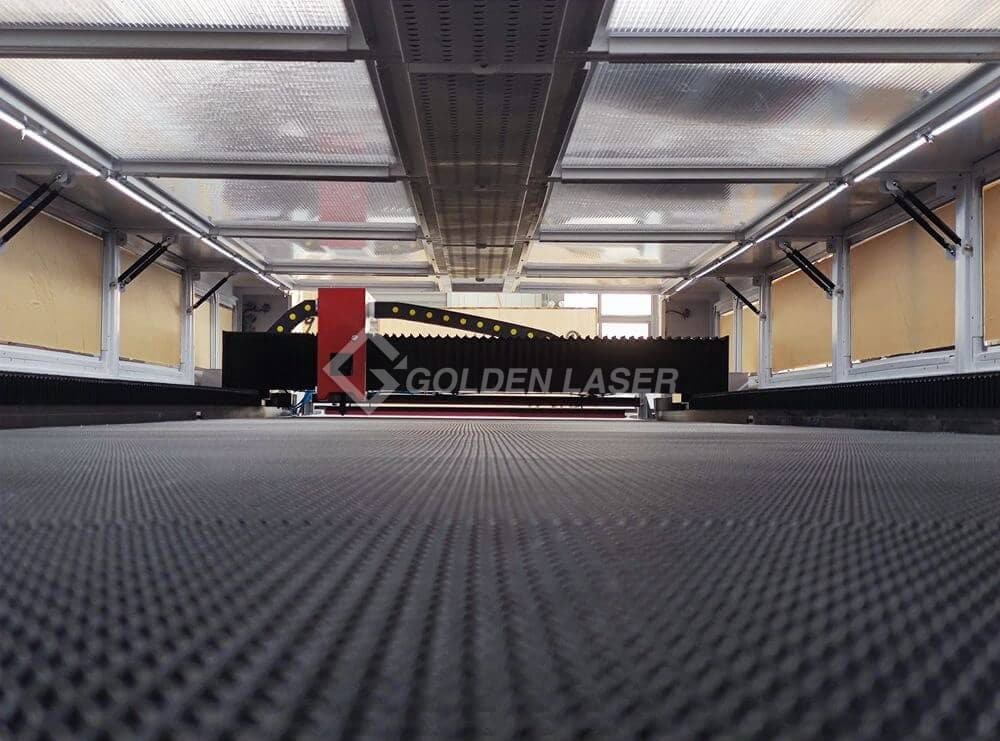

Vacuum conveyor working table |

| Mechanical system: |

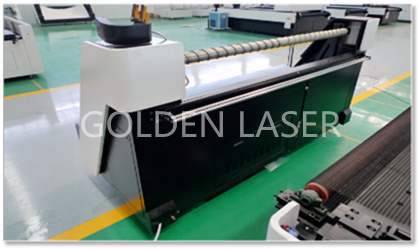

Servo motor; Gear and rack driven |

| Cutting speed: |

0~500mm/s |

| Acceleration: |

5000mm/s2 |

| Power supply: |

AC220V±5% 50/60Hz |

| Graphic format supported: |

AI, PLT, DXF, BMP, DST |

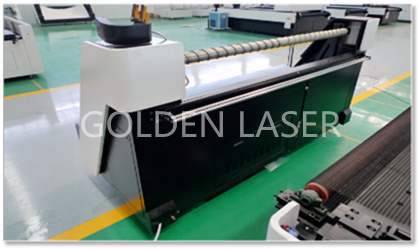

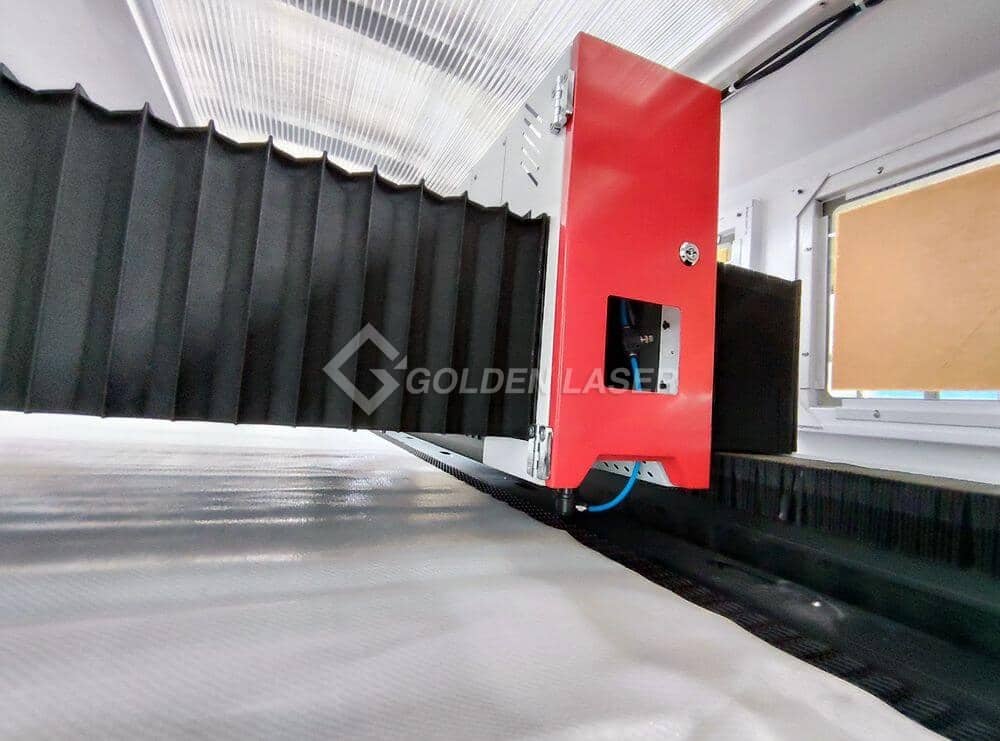

10 Meters Length CO2 Laser Cutting Machine Detailed Photos

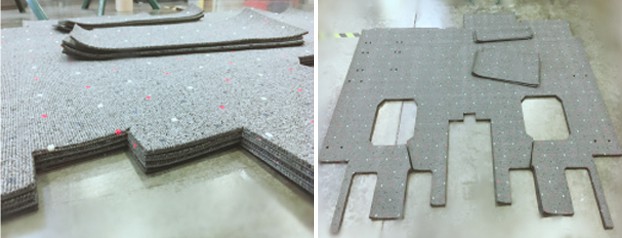

Material saving. The nesting software is easy to operate, professionally automatic nesting, eliminating the need for professional nesting personnel, saving 7% or even more materials.

Simplify the process. One machine for multi-purpose. Capable of handling cutting from roll to pieces, number marking on cut pieces and punch holes.

High precision. Laser spot size is up to 0.1mm, perfectly cutting angle, holes and a variety of complex designs and shapes.

Non-contact process. Clean and perfect cutting edges. Less efforts of clearance due to reduced dust production when cutting

Automation. Auto-feeder cooperates with software for automatic feeding. Thanks to the collecting working table, it solves the difficulties for collecting materials due to the large number of cut pieces.

Practicability. Perfectly cutting of polyester, polypropylene, non-woven, nylon, foam, cotton, PTFE and other textile materials.

› Handling extra long material, and continuous processing material in roll.

› Ensuring the maximum flatness and the lowest reflectivity.

› Automatic feeding system, rectify deviations automatically.

Customized optional extras simplify your production and increase your possibilities

CCD Camera Recognition System

Advantages of Cutting Textile with Laser Cutting Machine

Laser cutting with large working area

No fraying of fabric, no deformation of fabric

Simple production via a PC design program

Smooth and clean cutting edge, no reworking necessary

Complete extraction and filtering of the cutting emissions

Automated production process with conveyor and feeding systems

Watch Ultra-long Table Size Laser Cutter in Action!

Technical Parameter of the Flatbed CO2 Laser Cutting Machine

| Laser type |

CO2 glass laser tube / CO2 RF metal laser tube |

| Laser power |

150W / 300W |

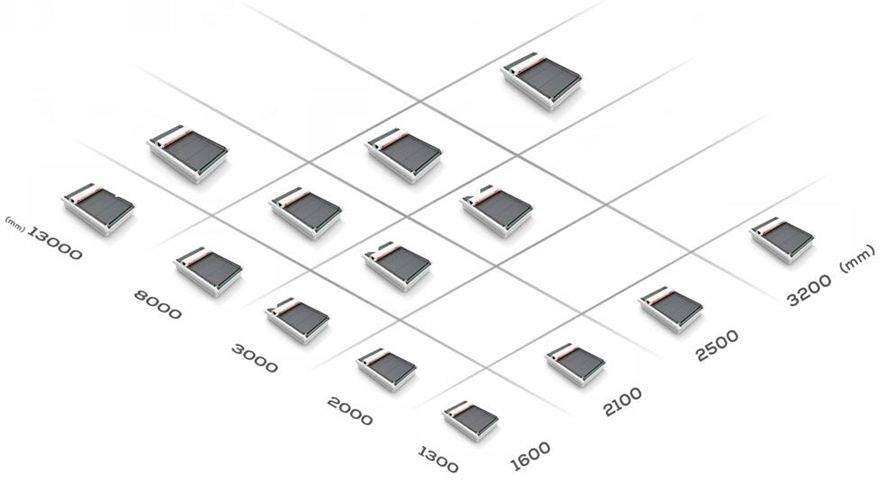

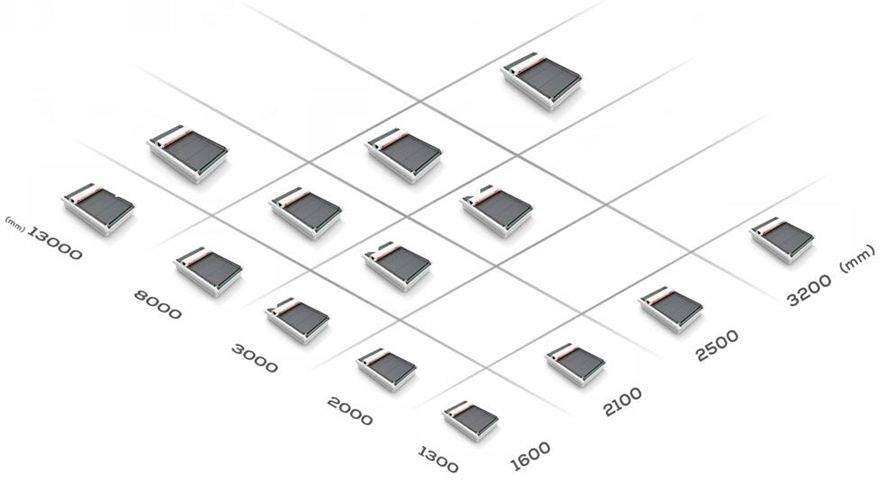

| Working area (W×L) |

1600mm, 2100mm, 2500mm (W) × 6000mm, 9000mm, 11000mm, 13000mm (L) |

| Working table |

Vacuum conveyor working table |

| Mechanical system |

Servo motor; Gear and rack driven |

| Cutting speed |

0~500mm/s |

| Acceleration |

5000mm/s2 |

| Power supply |

AC220V±5% 50/60Hz |

| Graphic format supported |

AI, PLT, DXF, BMP, DST |

GOLDENLASER CO2 Flatbed Laser Cutting Systems

Working areas: 1600mm × 2000mm (63″ × 79″), 1600mm × 3000mm (63″ × 118″), 2300mm × 2300mm (90.5″ × 90.5″), 2500mm × 3000mm (98.4″×118″), 3000mm × 3000mm (118″ × 118″), 3500mm × 4000mm (137.7″ × 157.4″), 3200mm x 8000mm (126″ x 315″), 1600mm x 6000mm (63″ x 236.2″), 1600mm x 9000mm (63″ x 354.3″), 1600mm x 13000mm (63″ x 511.8″), 2100mm x 11000mm (82.6″ x 433″), …

***The cutting area can be customized according to different applications.***

Laser Cutting Machine Application Field

Suitable for cutting polyester, nylon, Oxford fabric, canvas, polyamide, polypropylene, nonwoven, ripstop fabrics, Lycra, Mesh, EVA sponge, acrylic fabric, ETFE, PTFE, PE, vinyl, etc.

Laser Cutting industrial Fabrics Sample

Applicable to tent, awning, marquee, canopy, sailcloth, parachute, paraglider, parasail, inflatable castle ,sunshade, umbrella, soft signage, rubber boat, fire balloon, etc.

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?