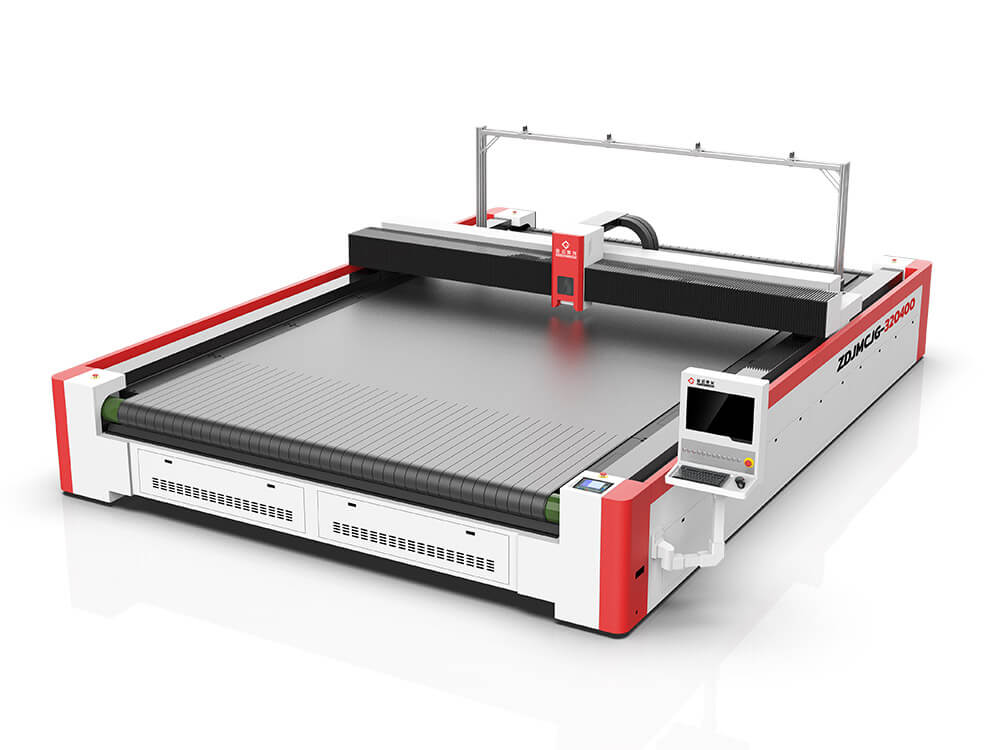

Wide Format Laser Cutting Machine for Flag, Banner, Soft Signage

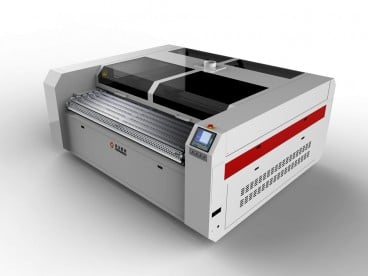

Model No.: CJGV-320400LD

Introduction:

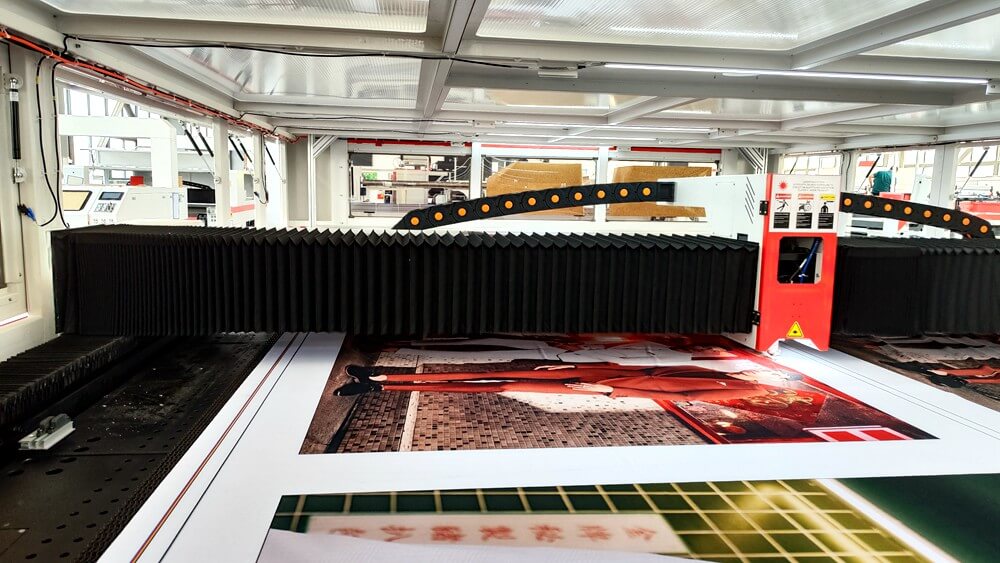

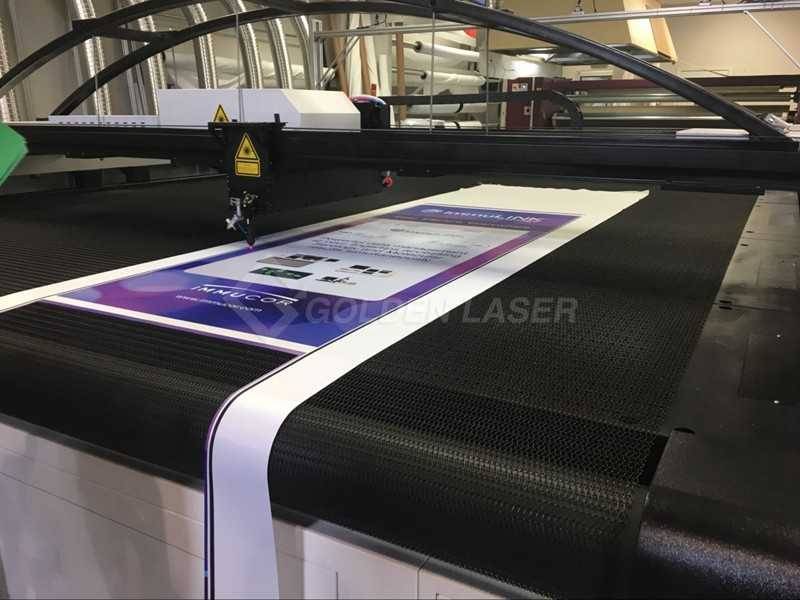

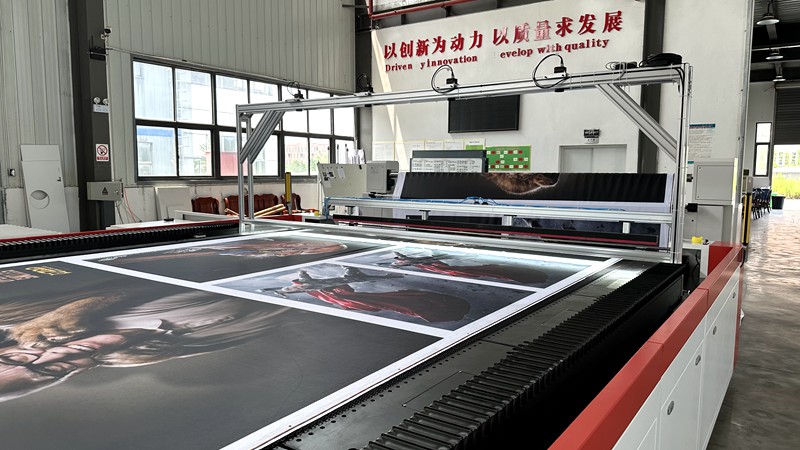

The large format vision laser cutting machine is specially designed for the digital printing industry - producing unparalleled capabilities for finishing wide format digitally printed or dye-sublimated textile graphics, banners, flags, displays, lightboxes, backlit fabric and soft signage.

- Working area : 3200mm×4000mm (10.5 ft×13.1ft)

- Camera scanning area : 3200mm×1000mm (10.5 ft×3.2ft)

- Laser tube : CO2 glass laser / CO2 RF metal laser

- Laser power : 150W / 200W / 300W

The Large Format Vision Textile Laser Cutting Machine is an innovative, highly proven, unique cutting solution designed specifically for the digital print industry and print service providers. This laser cutting machine delivers unparalleled capabilities for finishing wide format digitally printed or dye-sublimated textile graphics and soft-signage with customized cutting widths and lengths. Laser systems can be produced in width up to 3.2 meters and lengths up to 8 meters.

The system is equipped with an industrial class CO2 laser for cauterized finishing of polyester textiles. This method of sealing edges lends itself to a reduction in additional finishing steps such as hemming and sewing. A sophisticated camera vision registration system (VisionLaser) is standard. VisionLaser Cutter is ideal for cutting digital printed or dye-sublimation textile fabrics of all shapes and sizes.

|

Repeatability |

Speed |

Acceleration |

Laser power |

|

±0.1mm |

0-1200mm/s |

8000mm/s2 |

150W / 200W / 300W |

|

Working area |

3200mm×4000mm (10.5 ft×13.1ft) (can be customized) |

|

X-axis |

1600mm - 3200mm (63” - 126”) |

|

Y-axis |

2000mm - 8000mm (78.7” - 315”) |

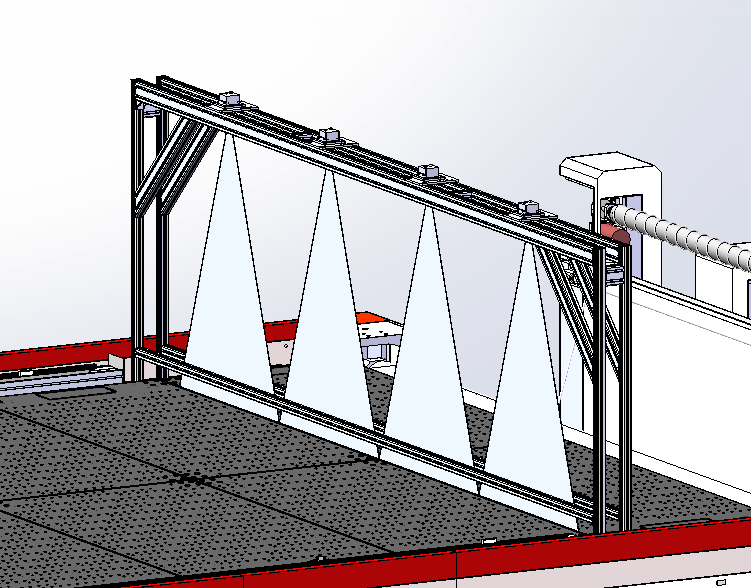

Simultaneous scanning by multiple cameras

FEATURES

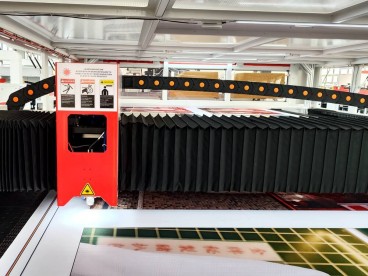

Rack and pinion drive structure

High-speed bilateral synchronous drive

Equipped with multiple HD cameras

Feeding and scanning are synchronized

Continuous and splice-free recognition of large-format printed textile graphics

Fully-enclosed safety enclosure available for enhanced safety protection

Distributed exhaust system

Effective absorption of fumes and dusts

Reinforced welded bed

Large gantry precision machining

Build your Image, Cut your Design

Discover More Photos of the CJGV-320400LD

Watch Large Format Vision Laser Cutter CJGV-320400LD in Action!

Technical Parameters of the Laser Cutting Machine

| Working area | 3.2m×4m (10.5 ft×13.1ft) |

| Camera scanning area | 3.2m×1m (10.5 ft×3.2ft) |

| Working table | Conveyor working table |

| Laser tube | CO2 glass laser tube / CO2 RF metal laser tube |

| Laser power | 150W / 200W / 300W |

| Control system | Servo motor system |

| Cooling system | Constant temperature water chiller |

| Exhaust system | 3KW exhaust fan×4 |

| Power supply | Laser cutter: 220V,50Hz or 60Hz/ single phase |

| Exhaust fan: 380V,50Hz or 60Hz/ three phase | |

| Electrical standard | CE / FDA / CSA |

| Software | Goldenlaser CAD scanner software package |

| Space occupation | 6.7m(L)×4.8m(W)×2.3m(H) / 21.9ft×15ft×7.5ft |

| Other option | Auto feeder, red dot |

GOLDENLASER Full Range of Vision Camera Laser Cutting Systems

Ⅰ High Speed Scan On-the-Fly Cutting Series

| Model No. | Working area |

| CJGV-160130LD | 1600mm×1300mm (63”×51”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

Ⅱ High Precision Cutting by Registration Marks

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

Ⅲ Ultra-Large Format Laser Cutting Series

| Model No. | Working area |

| ZDJMCJG-320400LD | 3200mm×4000mm (126”×157.4”) |

Ⅳ Smart Vision (Dual Head) Laser Cutting Series

| Model No. | Working area |

| QZDMJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

Ⅴ CCD Camera Laser Cutting Series

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

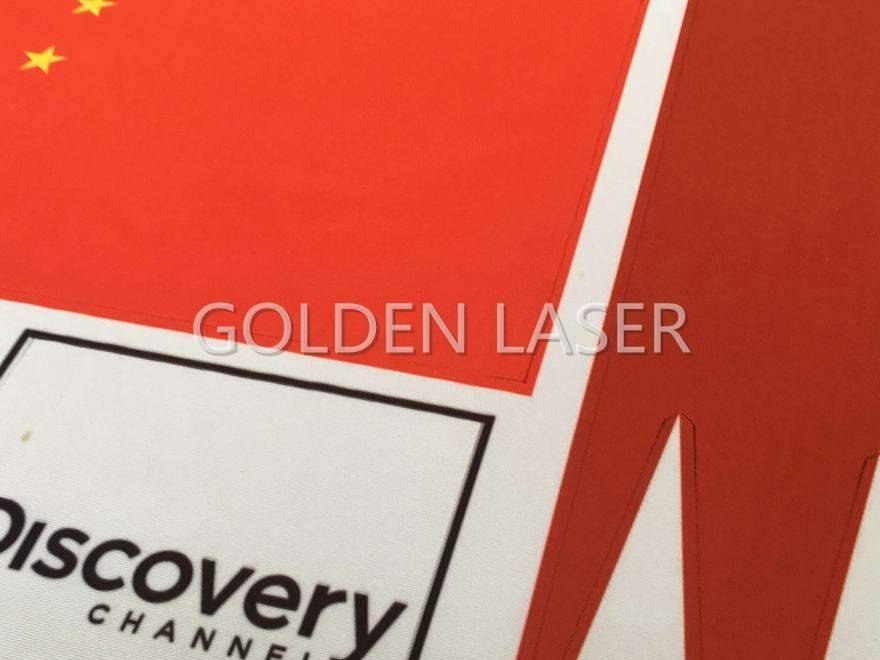

Wide Format Vision Laser Cutting Application

Flags, banners, soft signage, cartoon image, and more digitally printed or dye-sublimated textile.

Suitable for cutting polyester textiles, nylon, vinyl, etc.

<< Read More about Laser Cutting Banners, Flags, Soft-signage Samples