6000W 8000W Fiber Laser Cutting Machine

Model No.: GF-2560JH / GF-2580JH

Introduction:

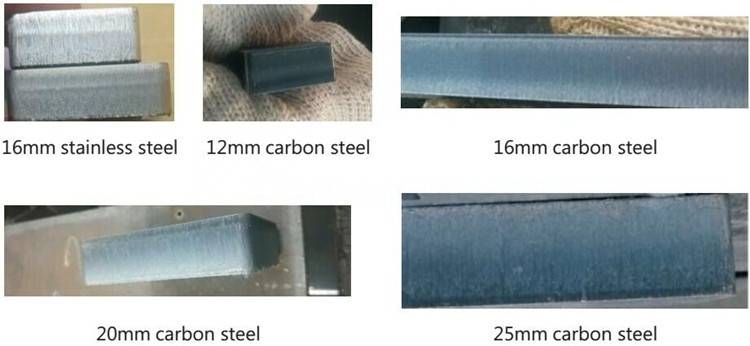

High power and large format fiber laser cutter. BECKHOFF CNC controller. 2.5m×6m, 2.5m×8m cutting area. Maximum cutting thickness 30mm CS, 16mm SS

- Laser Source : IPG / nLIGHT fiber laser generator

- Laser Power : 6000W / 8000W

- Laser Head : Raytools laser cutting head

- CNC Controller : Beckhoff controller

- Cutting Area : 2.5m×6m, 2.5m×8m

- Max. Cutting Thickness : 30mm CS, 16mm SS

Full Closed Fiber Laser Cutting Machine with Exchange Table

GF-JH series 6000W 8000W fiber laser cutting machine is equipped with nLIGHT laser generator as well as efficient drive mechanism such as high precision gear rack, high precision linear guide rail, and assembled through the advanced BECKHOFF CNC controller. It is a hi-tech system integrating laser cutting, precision machinery and CNC technology. Mainly used for cutting and forming carbon steel sheets, stainless steel sheets, aluminum alloys, composite materials, etc. With the features of high speed, high precision, high efficiency and high cost performance, it is specially for cutting larger format metal sheets, with the cutting area 1500mm×3000mm and 2500mm×8000mm. The 6000W fiber laser cutting machine can cut a maximum thickness of 25mm carbon steel and 12mm stainless steel.

BECKHOFF controller

1. In combination with the Motion Control solutions offered by the TwinCAT automation software, Beckhoff Drive Technology represents an advanced and complete drive system.

2. PC-based control technology from Beckhoff is ideally suited for single and multiple axis positioning tasks with highly dynamic requirements.

3. BECKHOFF latest single cable technology, combined power and coding cable into one, which can eliminate signal interference.

4. High-precision photoelectric sensors and mechanical travel switches are installed on all the moving parts of the machine, which can capture every movement moment, and control machine act instantly.

5. System signal transmission without interference, make sure the machine running with high dynamic, energy efficient and low cost.

Automatic shuttle table

1. Integrated shuttle tables maximize the productivity and minimize the material handing times. The shuttle table changing system allows convenient loading of new sheets after unloading of the finished parts while the machine is cutting another sheet inside working area.

2. The shuttle tables are fully electric and maintenance free. The table changes take place fast, smooth and energy-efficient.

| Model number | GF-2560JH / GF-2580JH |

| Cutting area | 1.5m×3m, 2×4m, 2m×6m, 2.5m×6m, 2.5m×8m |

| Laser source | fiber laser resonator IPG/Nlight |

| Laser source power | 1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W |

| Position accuracy | +0.03mm/m |

| Repeat position accuracy | +0.02mm |

| Acceleration speed | 2G |

| Cutting speed | depend on material and laser source power |

| Electric power supply | AC380V 50/60Hz |

GOLDEN LASER - FIBER LASER CUTTING SYSTEMS SERIES

|

Model NO. |

P2060 |

P3080 |

|

Pipe Length |

6000mm |

8000mm |

|

Pipe Diameter |

20mm-200mm |

20mm-300mm |

|

Laser Power |

700W / 1000W / 2000W / 2500W / 3000W / 4000W / 6000W |

|

Full Closed Pallet Table Fiber Laser Cutting Machine |

||

|

Model NO. |

Laser Power |

Cutting Area |

|

GF-1530JH |

700W / 1000W / 2000W / 2500W / 3000W / 4000W / 6000W / 8000W |

1500mm×3000mm |

|

GF-2040JH |

2000mm×4000mm |

|

High Speed Single Mode Fiber Laser Metal Cutting Machine |

||

|

Model NO. |

Laser Power |

Cutting Area |

|

GF-1530 |

700W |

1500mm×3000mm |

Dual Function Fiber Laser Sheet & Tube Cutting Machine |

||

|

Model NO. |

Laser Power |

Cutting Area |

|

GF-1530T |

700W / 1000W / 2000W / 2500W / 3000W |

1500mm×3000mm |

|

GF-1540T |

1500mm×4000mm |

|

|

GF-1560T |

1500mm×6000mm |

|

| Small Size Fiber Laser Metal Cutting Machine | ||

|

Model NO. |

Laser Power |

Cutting Area |

|

GF-6040 |

700W / 1000W |

600mm×400mm |

|

GF-5050 |

500mm×500mm |

|

|

GF-1309 |

1300mm×900mm |

|

Applicable Materials

Stainless steel, carbon steel, aluminum, brass, copper, galvanized steel, alloy steel etc.

Applicable Field

Rail transportation, automobile, engineering machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household electrical appliances, grain machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchen utensils, decoration advertising, laser processing services and other machinery manufacturing industries etc.

High Power Fiber Laser Cutting Metal Sheets Samples