We are here to help with customization options to meet your specific manufacturing needs.

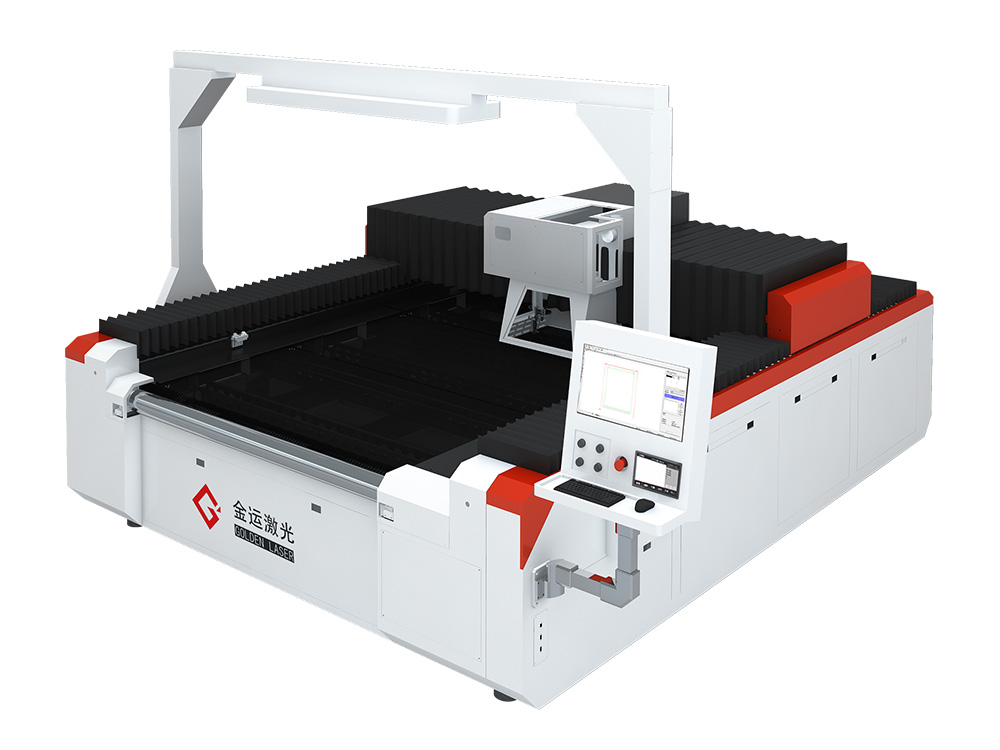

High Speed Laser Perforation and Cutting Machine with Camera

Model No.: ZDJMCZJJG(3D)170200LD

Introduction:

This laser cutting system seamlessly combines the precision of Galvo and the versatility of Gantry, offering high-speed performance for a diverse range of materials while also optimizing space utilization with its multi-functional capabilities.

Additionally, its adaptability to integrate different vision camera systems allows for automatic recognition of contours and precise edge-cutting for printed materials. This capability enhances efficiency and accuracy, particularly in the fashion and digital printing (dye-sublimation) fabric applications.

- Processing format : 1700mmx2000mm (can be customized on demand)

- Laser power : 150W / 200W /300W

- Repeatability : ±0.1mm

- Galvo speed : 0-8000mm/s

- Gantry speed : 0-800mm/s

- Option : Auto feeder

Highlights of the Machine Structure

The Galvo & Gantry integrated design allows the machine to seamlessly transition between two distinct motion control systems: the galvanometer system and the gantry system.

1. Galvanometer System:

The galvanometer system is known for its high-speed and precision in controlling the laser beam. It employs a set of mirrors that can rapidly reposition to direct the laser beam across the material surface. This system is exceptionally effective for intricate and detailed work, providing swift and accurate laser movements for tasks such as perforating and fine cutting.

2. Gantry System:

On the other hand, the gantry system involves a larger-scale motion control mechanism, typically consisting of a gantry structure with a moving laser head. This system is advantageous for covering larger surface areas and is well-suited for applications that require broad, sweeping movements.

Automatic Switching Mechanism:

The brilliance of the automatic switching feature lies in its ability to seamlessly transition between these two systems based on the specific requirements of the job at hand. This feature is often software-controlled and can be programmed to engage the galvanometer system for intricate detailing and then switch to the gantry system for broader, less detailed tasks, all without manual intervention.

Benefits:

- • Versatility: The machine can adapt to a wide range of applications, from intricate designs to larger, more expansive cutting tasks.

- • Optimized Efficiency: The automatic switching ensures that the most suitable motion control system is employed for each part of the job, maximizing efficiency and reducing processing time.

- • Precision and Speed: Combining the strengths of both systems, this feature allows for a harmonious balance between precision and speed in laser processing.

MACHINE FEATURES

Golden Laser's High-Speed Galvo & Gantry Laser Machine - your partner in precision and efficiency.

Rack and Pinion Drive

Precision meets speed with our robust rack and pinion drive structure, ensuring high-speed bilateral synchronous drive for efficient perforating and cutting processes.

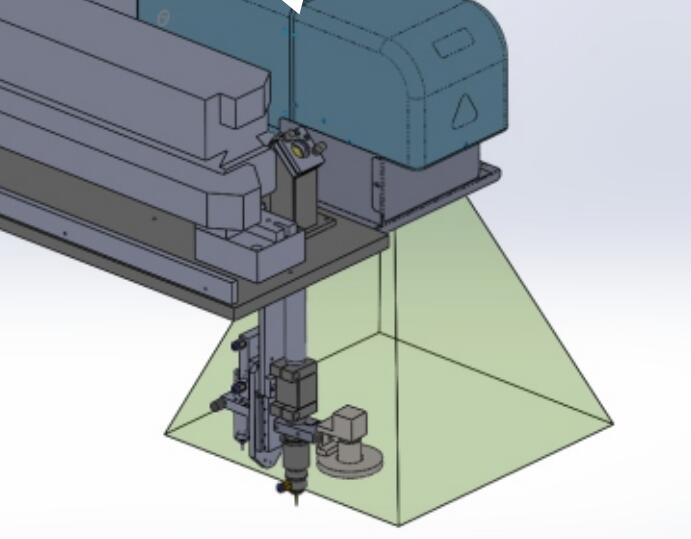

3D Dynamic Galvo System

Experience unmatched accuracy and flexibility with our advanced three-axis dynamic galvanometer control system, delivering precise laser movements for superior results.

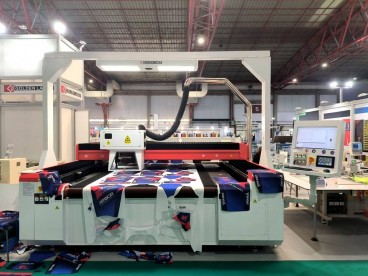

Vision Camera System

Equipped with state-of-the-art high-definition industrial cameras, our machine ensures advanced visual monitoring and precise material alignment, guaranteeing perfection in every cut.

Motion Control System

Benefit from cutting-edge technology of a closed-loop motion control system with with independent intellectual property rights, ensuring superior performance and reliability.

Follow-Up Exhaust Device

Keep your workspace clean and efficient with our follow-up exhaust device, swiftly and cleanly removing smoke from the cutting process.

Reinforced Welded Bed

The machine features a reinforced welded bed and large-scale gantry precision milling, providing a stable foundation for accurate and reliable laser processing.

Application

Golden Laser's High-Speed Galvo & Gantry Laser Machine - Ideal for a wide range of industries, including:

1. Sportswear and Activewear:

Specifically designed for creating ventilation holes and intricate patterns on sportswear, gym apparel, and leggings.

2. Apparel, Fashion and Accessories:

Perfect for precision cutting and perforation of fabric for clothing items, ensuring clean edges and intricate designs.

3. Leather and Footwear:

Ideal for perforating and cutting leather used in the production of shoes and other leather goods like gloves.

4. Decorative Items:

Precision cutting for creating intricate patterns on decorative items such as tablecloths and curtains.

5. Industrial Fabrics:

Ideal for cutting and perforating fabrics used in automotive interiors, fabric ducts an other technical textiles.

Enhance your production capabilities with the High Speed Galvo & Gantry Laser Perforating and Cutting Machine from Golden Laser.

Technical Parameters

| Working area | 1700mmx2000mm / 66.9”x78.7” (customizable on demand) |

| Working table | Conveyor working table |

| Laser power | 150W / 200W / 300W |

| Laser tube | CO2 RF metal laser tube |

| Cutting system | X-Y gantry cutting |

| Perforation/marking system | GALVO system |

| X-axis moving system | Gear and rack moving system |

| Y-axis moving system | Gear and rack moving system |

| Cooling system | Constant temperature water chiller |

| Exhaust system | 3KW exhaust fan x 2, 550W exhaust fan x 1 |

| Power supply | AC220V ± 5%, 50Hz/60Hz |

| Software | Golden Laser Marking and Cutting Software |

| Space occupation | 3993mm(L) x 3550mm(W) x 1600mm(H) / 13.1’ x 11.6’ x 5.2’ |

| Other options | Auto feeder, red dot |

*** Note: As products are constantly updated, please contact us for the latest specifications. ***

GOLDENLASER Full Range of Sublimation Laser Cutting Systems

① Vision Scanning Laser Cutting Machine

| Model No. | Working area |

| CJGV-160130LD | 1600mm×1200mm (63”×47.2”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

② Camera Recognition Laser Cutting Machine (GoldenCam)

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

③ Smart Vision Laser Cutting Machine

| Model No. | Working area |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

| QZDXBJGHY-180100LDII | 1800mm×1000mm (70.8”×39.3”) |

④ Galvanometer Flying Vision Laser Cutting Machine

| Model No. | Working area |

| ZJJF(3D)-160160LD | 1600mm×1600mm (63”×63”) |

⑤ Large Format Vision Laser Cutting Machine for Advertising Banners and Flags

| Model No. | Working area |

| CJGV-320400LD | 3200mmx4000mm (10.5 ftx13.1ft) |

⑥ High Speed Perforation and Cutting Laser Machine with Vision System

| Model No. | Working area |

| ZDJMCZJJG(3D)170200LD | 1700mmx2000mm (66.9”x78.7”) |

The High Speed Galvo & Gantry Laser Perforating and Cutting Machine with Camera from Golden Laser is versatile and can be applied to a wide range of materials. Here are specific materials that the machine can effectively process:

1. Sportswear and Activewear Fabrics:

Technical fabrics, moisture-wicking materials, and stretchable fabrics commonly used in sportswear, activewear, and leggings.

2. Fabrics for Apparel:

Cotton, polyester, silk, nylon, spandex, and other textile materials used in garment production.

3. Leather Materials:

Genuine leather, synthetic leather, and suede for various applications in the fashion and footwear industries.

4. Textile Home Decor Items:

Fabrics for headscarves, tablecloths, curtains, and other decorative textiles used in home furnishings.

5. Industrial Fabrics:

Automotive interior fabrics, fabric ducts, and other heavy-duty materials used in industrial applications.

It’s important to note that the machine’s precision and versatility make it suitable for a broader range of materials within these categories. Additionally, the ability to create intricate patterns and perforations enhances the customization options for various industries. If you have specific materials in mind for your application, the machine can likely accommodate them, provided they fall within the specified processing format and thickness capabilities.