Otomatis Bundle Loader Fiber Laser Pipe Cutting Machine

Nomer Model: P2060A / P3080A

Pambuka:

- Panjang pipa:6000mm / 8000mm

- Diameter pipa:20mm-200mm / 30mm-300mm

- ukuran loading:800mm * 800mm * 6000mm / 800mm * 800mm * 8000mm

- Daya laser:1000W 1500W 2000W 2500W 3000W 4000W

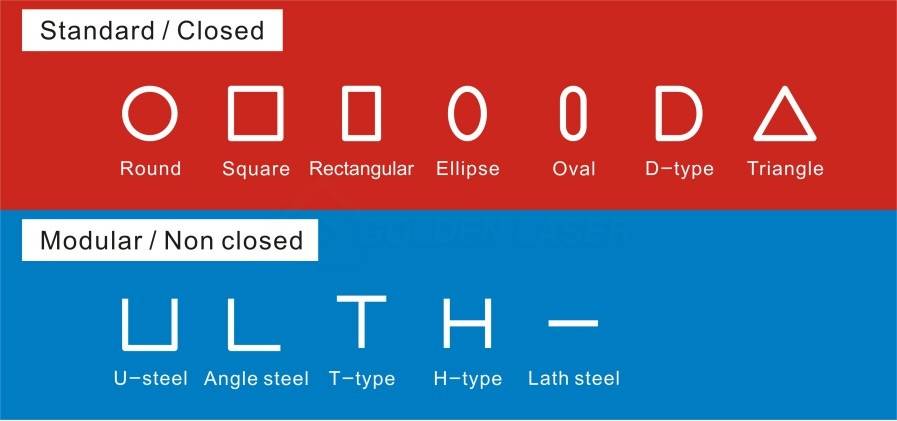

- Tipe tabung sing ditrapake:Tabung bunder, tabung persegi, tabung persegi panjang, tabung oval, D-jinis T-shaped baja H-shaped, baja saluran, baja sudut, etc.

- Bahan sing ditrapake:Stainless steel, baja ringan, galvanis, tembaga, kuningan, aluminium, dll.

Auto Bundle Loader Tube Laser Cutting Machine

Kita tansah ningkatake lan nganyarke kinerja mesin pemotong laser tabung.

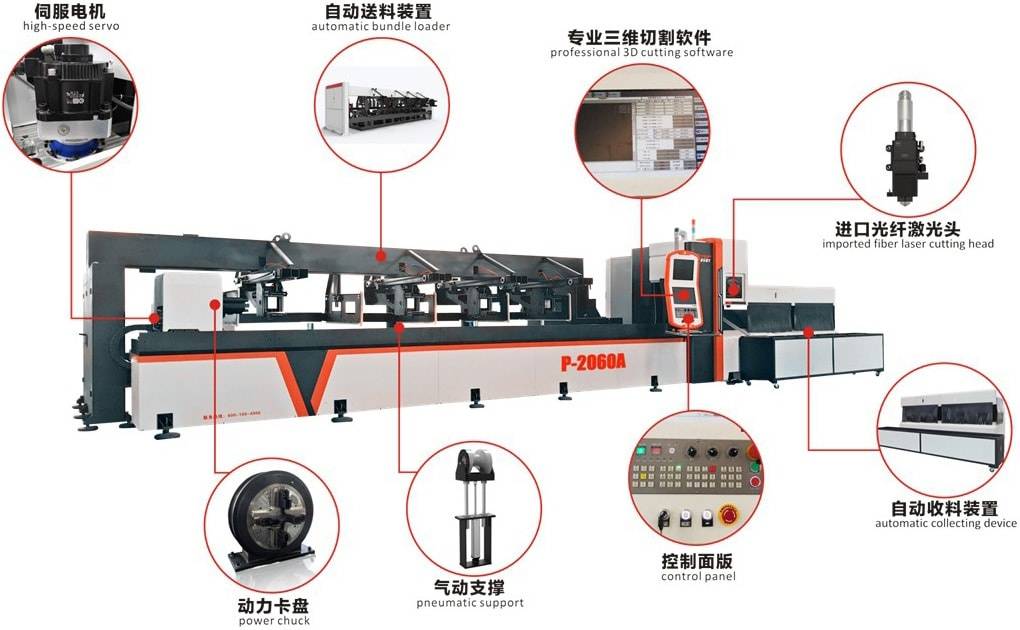

Komponen

Details Tube Laser Cutting Machine

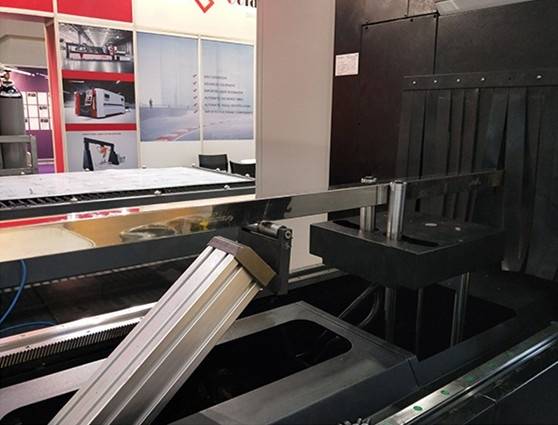

Loader Bundle Otomatis

Loader bundle otomatis ngirit tenaga kerja lan wektu loading, nyebabake tujuan produksi massal.

Pipa bunder lan pipa persegi panjang bisa diisi kanthi otomatis tanpa campur tangan manungsa. Pipa shaped liyane bisa dipakani semi-otomatis kanthi manual.

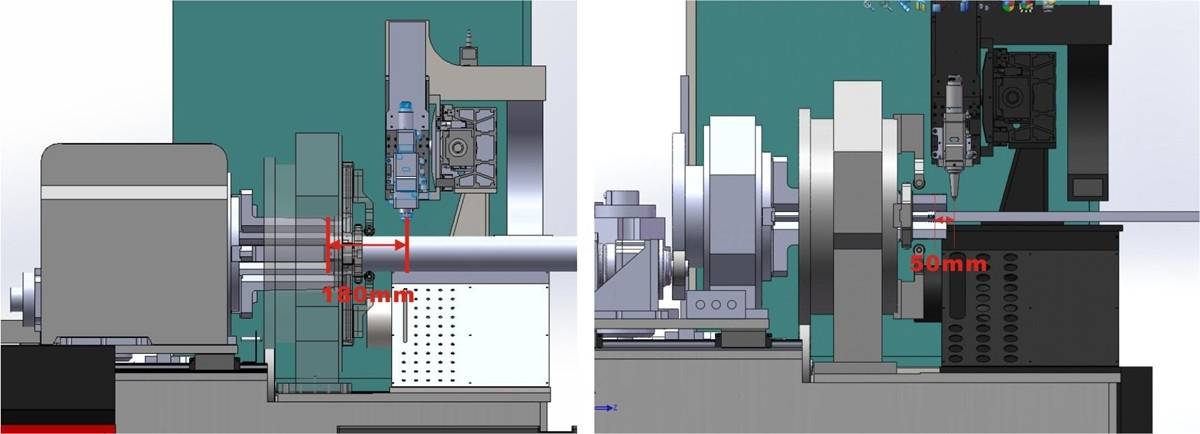

Sistem pemasangan chuck canggih

Dhukungan ngambang materi ndhuwur

Dhukungan Ngambang / Piranti Nglumpukake

Link telung sumbu

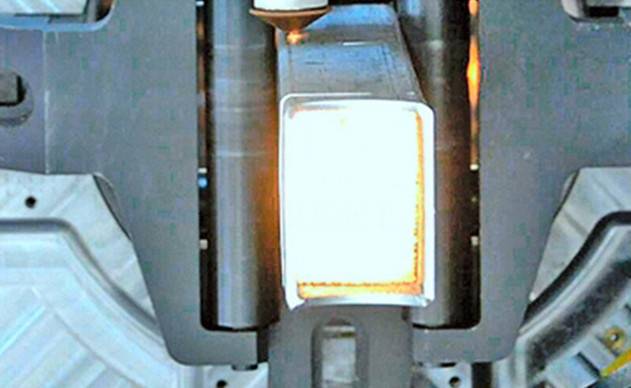

Welding jahitan pangenalan

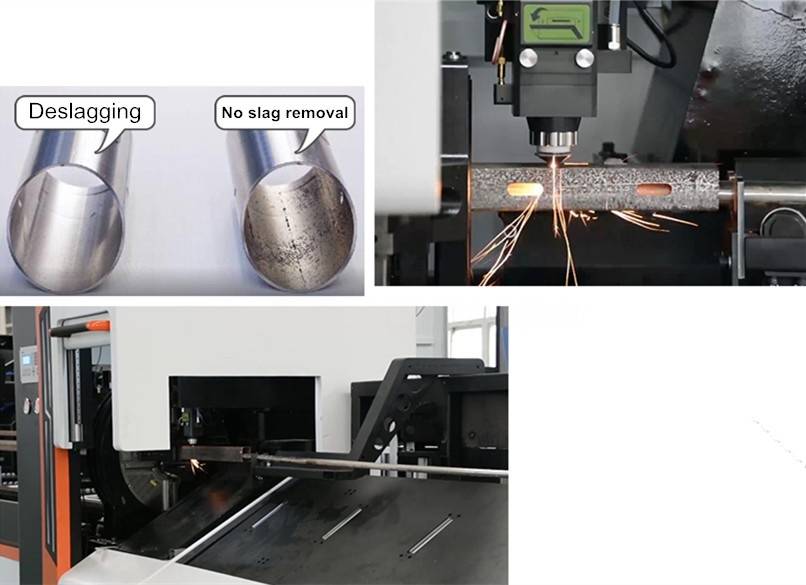

Hardware - boroske

Opsional - sumbu katelu ngresiki piranti tembok njero

Tube Laser Cutting Sampel

Parameter teknis

| Nomer model | P2060A |

| daya laser | 1000W / 1500W / 2000W / 2500W / 3000W / 4000W |

| sumber laser | IPG/nLight fiber laser resonator |

| Dawane tabung | 6000 mm |

| Diameter tabung | 20mm ~ 200mm |

| Tipe tabung | Bunder, kothak, persegi dowo, oval, OB-jinis, C-jinis, D-jinis, segi telu, etc (standar); Baja sudut, baja saluran, baja bentuk H, baja bentuk L, dll. (pilihan) |

| Baleni akurasi posisi | ± 0,03 mm |

| Akurasi posisi | ± 0,05 mm |

| Kacepetan posisi | Maks. 90m / min |

| Kacepetan puteran Chuck | Maks. 105r/min |

| Akselerasi | 1.2g |

| Format grafis | Solidworks, Pro/e, UG, IGS |

| Ukuran bundle | 800mm * 800mm * 6000mm |

| Bobot bundle | Max 2500kg |

EMAS LASER - SERAT LASER nglereni SYSTEMS SERIES

| Model NO. | P2060A | P3080A |

| Panjang Pipa | 6m | 8m |

| Diameter Pipa | 20mm-200mm | 20mm-300mm |

| Daya Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W | |

| Model NO. | P2060 | P3080 |

| Panjang Pipa | 6m | 8m |

| Diameter Pipa | 20mm-200mm | 20mm-300mm |

| Daya Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W | |

| Model NO. | P30120 |

| Panjang Pipa | 12 mm |

| Diameter Pipa | 30mm-300mm |

| Daya Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

| Model NO. | Daya Laser | Area Pemotongan |

| GF-1530 | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W | 1500mm × 3000mm |

| GF-1560 | 1500mm × 6000mm | |

| GF-2040 | 2000mm × 4000mm | |

| GF-2060 | 2000mm × 6000mm | |

| Model NO. | Daya Laser | Area Pemotongan |

| GF-1530T | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W | 1500mm × 3000mm |

| GF-1560T | 1500mm × 6000mm | |

| GF-2040T | 2000mm × 4000mm | |

| GF-2060T | 2000mm × 6000mm | |

| Model NO. | Daya Laser | Area Pemotongan |

| GF-6060 | 700W / 1000W / 1200W / 1500W | 600mm × 600mm |

Industri Aplikasi

Utamane digunakake ing peralatan fitness, perabot kantor, rak, struktur baja, industri medis, rak rel lan industri liyane kanggo pipa bunder, tabung persegi, tabung persegi panjang lan pipa shaped lan pangolahan profil liyane.

Materi sing ditrapake

Stainless steel, baja karbon, aluminium, kuningan, tembaga, baja galvanis, baja paduan.

Jinis Tube sing ditrapake

Mesin Pemotong Laser Tube kanggo Produksi Massal ing Situs Pelanggan

Hubungi goldenlaser kanggo informasi luwih lengkap. Tanggepan saka pitakonan ing ngisor iki bakal mbantu nyaranake mesin pemotong laser tabung sing paling cocok.

1, Apa jinis tabung sampeyan kudu dipotong laser? Tabung bunder, tabung persegi, tabung persegi panjang, tabung oval utawa tabung bentuk liyane?

2. Apa jenis logam iku? Baja ringan utawa stainless steel utawa aluminium utawa..?

3. Apa kekandelan tembok, diameter lan dawa tabung?

4. Apa produk rampung saka tabung? (Apa industri aplikasi?)

5. Jeneng perusahaan, situs web, Email, Telp (WhatsApp / WeChat)?