Mochini oa ho Seha oa Roll-to-Roll Laser Die o nang le bokhoni ba ho Slitting le Sheeting

Nomoro ea mohlala: LC350/LC520

Selelekela:

Sistimi e tloaelehileng ea dijithale ea laser die-cutting e kopanya laser die-cutting, slitting, le sheeting ho e le 'ngoe. E na le kopanyo e phahameng, automation, le bohlale. Ho bonolo ho sebetsa, ho ntlafatsa haholo katleho ea tlhahiso le ho fokotsa mosebetsi oa matsoho. E fana ka tharollo e sebetsang le e bohlale ea laser die-cuting bakeng sa tšimo ea ho seha lefu.

Sistimi ena ea Roll-to-Roll Laser Die-Cutting e etselitsoe tlhahiso ea lebelo le holimo, e tsoelang pele, e kopanyang mesebetsi e meraro ea mantlha: laser die-cutting, slitting, le sheeting. E etselitsoe ts'ebetso ea othomathike ka botlalo ea lisebelisoa tsa roll joalo ka lileibole, lifilimi, litheipi tsa sekhomaretsi, li-circuit substrates tse feto-fetohang, le li-liner tsa tokollo tse nepahetseng. E sebelisa mokhoa o mocha oa ts'ebetso oa Roll-to-Roll (R2R), sistimi e kopanya ntle ho tšitiso, ts'ebetso ea laser, le ho khutlisa morao, e nolofalletsang tlhahiso e tsoelang pele ea nako ea ho theoha. E ntlafatsa haholo ts'ebetso le chai, e sebetsang liindastering tse kang ho paka, ho hatisa, lisebelisoa tsa elektroniki, masela le lisebelisoa tsa bongaka.

Likarolo tsa Bohlokoa

E sebelisa theknoloji e tsoetseng pele ea laser, sistimi e etsa ts'ebetso e rarahaneng ea lisebelisoa tse fapaneng, ho kenyeletsoa lileibole, lifilimi, lisebelisoa tsa ho paka tse tenyetsehang, le lihlahisoa tsa sekhomaretsi, e fana ka seha se sa amaneng, se nepahetseng haholo.

• Mohloli oa laser oa CO2 (ka boikhethelo ho mohloli oa laser ea Fiber/UV)

• Mokhoa o phahameng oa ho nepahala oa Galvo oa ho hlahloba

• E khona ho itšeha ka botlalo, ho seha halofo (kiss cutting), ho phunya, ho betla, ho hlaba, le ho seha mela.

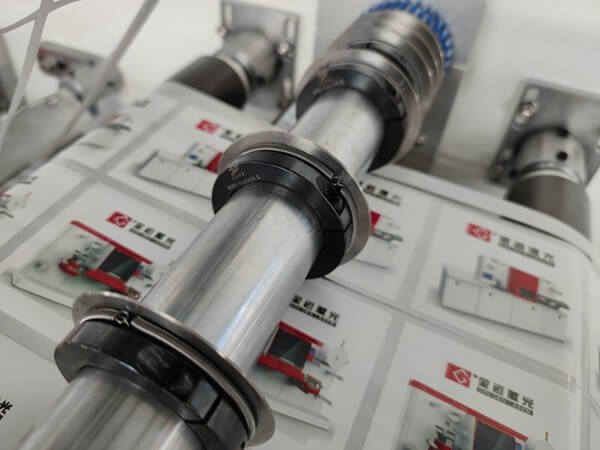

Mojule o kopantsoeng oa slitting o arola ka nepo lisebelisoa tse pharaletseng ka meqolo e mengata e moqotetsane ha ho hlokahala, e sebetsana le litlhoko tse fapaneng tsa tlhahiso.

• Ho na le mekhoa e mengata ea ho petsola (ho seha ka rotary shear, ho petsola lehare)

• Fetola bophara slitting

• Mokhoa o ikemetseng oa taolo ea tsitsipano bakeng sa boleng bo tsitsitseng ba ho khaola

Ka ts'ebetso e kopaneng ea sheeting, mochini oa laser die-cuting o ka arola lisebelisoa tse sebetsitsoeng ka kotloloho, o amohela mefuta e fapaneng ea odara ho tloha ho lihlopha tse nyane ho isa tlhahisong e kholo habonolo.

• Thipa ea rotary e phahameng ka ho fetisisa / sehahi sa guillotine

• Bolelele bo ka feto-fetohang ba ho itšeha

• Automatic stacking / pokello mosebetsi

E na le sebopeho se bohlale sa mosebelisi le software e tsoetseng pele ea othomathike, basebelisi ba ka khona ho fetola maemo a ho itšeha habonolo, litempele tsa moralo, le ho beha leihlo boemo ba tlhahiso, ba fokotsa haholo nako ea ho seta.

Sistimi ea khamera e nang le:

•E lemoha Matshwao a Ngodiso: E netefatsa tlhophiso e nepahetseng ya laser cut le meralo e hatisitsweng esale pele.

•Ho hlahloba Mefokolo: E hlwaya mefokolo ea thepa kapa mokhoa oa ho itšeha.

•Litokiso tse Iketselitsoeng: E lokisa tsela ea laser ka boiketsetso ho lefella ho fapana ha thepa kapa khatiso.

Laser Die Cutting Melemo Ho Feta Setso sa Ho Seha Lefu:

Kopo

-

Labels le Package:Tlhahiso e sebetsang ea lileibole tse ikhethileng le lisebelisoa tsa ho paka tse tenyetsehang.

-

Ntlafatso ea Lintho tsa Elektronike:Ho itšeha ho nepahetseng ha lipotoloho tse feto-fetohang, lifilimi tse sireletsang, lifilimi tse tsamaisang, le lisebelisoa tse ling.

-

Lisebelisoa tse ling tsa indasteri:Ts'ebetso ea lisebelisoa tsa bongaka, lisebelisoa tsa papatso, le lisebelisoa tse khethehileng tse sebetsang.

| LC350 | LC520 | |

| Max Web Width | 350 limilimithara | 520 limilimithara |

| Matla a Laser | 30W / 60W / 100W / 150W / 200W / 300W / 600W | |

| Hlooho ea Laser | Hlooho e le 'ngoe ea laser / Lihlooho tse ngata tsa laser | |

| Ho Seha ho Nepaha | ±0.1mm | |

| Phepelo ea motlakase | 380V 50/60Hz Mokhahlelo oa boraro | |

| Litekanyo tsa Mochini | 5.6m×1.52m×1.78m | 7.6m×2.1m×1.88m |

Golden Laser Die-Cutting Machine Model Summary

| Mofuta oa Roll-to-Roll | |

| Standard Digital Laser Die Cutter e nang le Mosebetsi oa Sheeting | LC350 / LC520 |

| Hybrid Digital Laser Die Cutter (Roll to roll and Roll to sheet) | LC350F / LC520F |

| Digital Laser Die Cutter bakeng sa Li-Labels tsa mebala e phahameng | LC350B / LC520B |

| Multi-station Laser Die Cutter | LC800 |

| MicroLab Digital Laser Die Cutter | Setšoantšo sa LC3550JG |

| Mofuta oa Sheet-Fed | |

| Sheet Fed Laser Die Cutter | LC1050 / LC8060 / LC5035 |

| Bakeng sa ho Seha Filimi le Theipi | |

| Laser Die Cutter bakeng sa Film le Theipi | LC350 / LC1250 |

| Ho arola mofuta oa Laser Die Cutter bakeng sa Filimi le Theipi | LC250 |

| Ho Seha Maqephe | |

| Sekhahla se phahameng sa Laser Cutter | JMS2TJG5050DT-M |

Lisebelisoa:

Mechini ena e ka sebetsana le lisebelisoa tse fapaneng tse tenyetsehang, ho kenyelletsa:

- • Pampiri: Lipampiri, mabokose, sephutheloana.

- • Lifilimi: PET, BOPP, PP, Polyimide (Kapton), joalo-joalo E sebelisetsoa li-labels, li-circuits tse feto-fetohang, le ho paka.

- • Likhomaretsi: Litheipi, li-labels, li-decals.

- • Masela: Masela a lohiloeng le a sa lohiloeng.

- • Foils: Aluminium, koporo.

- • Laminates: Lisebelisoa tse nang le lihlopha tse ngata.

Lisebelisoa:

- • Labels: Ho hlahisa lileibole tse bōpehileng ka mokhoa o ikhethileng tse nang le meralo e rarahaneng.

- • Sephutheloana: Ho iketsetsa libopeho le boholo ba sephutheloana.

- • Electronics: Ho hlahisa li-circuits tse feto-fetohang, likaroloana tsa li-sensor.

- • Lisebelisoa tsa Bongaka: Lisebelisoa tsa ho seha bakeng sa lipache tsa bongaka, lisebelisoa.

- • Likoloi: Lisebelisoa tsa ho etsa lihlahisoa tsa ka hare, li-label.

- • Textiles: Ho seha mekhoa ea liaparo, upholstery.

- • Sepakapaka: Lisebelisoa tsa ho seha bakeng sa likarolo tsa sefofane.

- • Prototyping: Ho theha ka potlako litšoantšo tsa meralo e mecha.

Ka kopo ikopanye le goldlaser bakeng sa lintlha tse ling. Karabo ea hau lipotsong tse latelang e tla re thusa ho khothaletsa mochine o loketseng ka ho fetisisa.

1. Tlhokahalo ea hau ea mantlha ea ts'ebetso ke efe? Laser cutting kapa laser fatling (ho tšoaea) kapa laser perforating?

2. Ke lintho life tseo u li hlokang bakeng sa ts'ebetso ea laser?

3. Boholo le botenya ba thepa ke bofe?

4. Ka mor'a hore laser e sebetsoe, thepa e tla sebelisoa bakeng sa eng? (indasteri ea kopo) / Sehlahisoa sa hau sa ho qetela ke sefe?

5. Lebitso la k'hamphani ea hau, sebaka sa marang-rang, Email, Tel (WhatsApp / WeChat)?