Large Format Laser Cutting Machine for Outdoor Fabrics

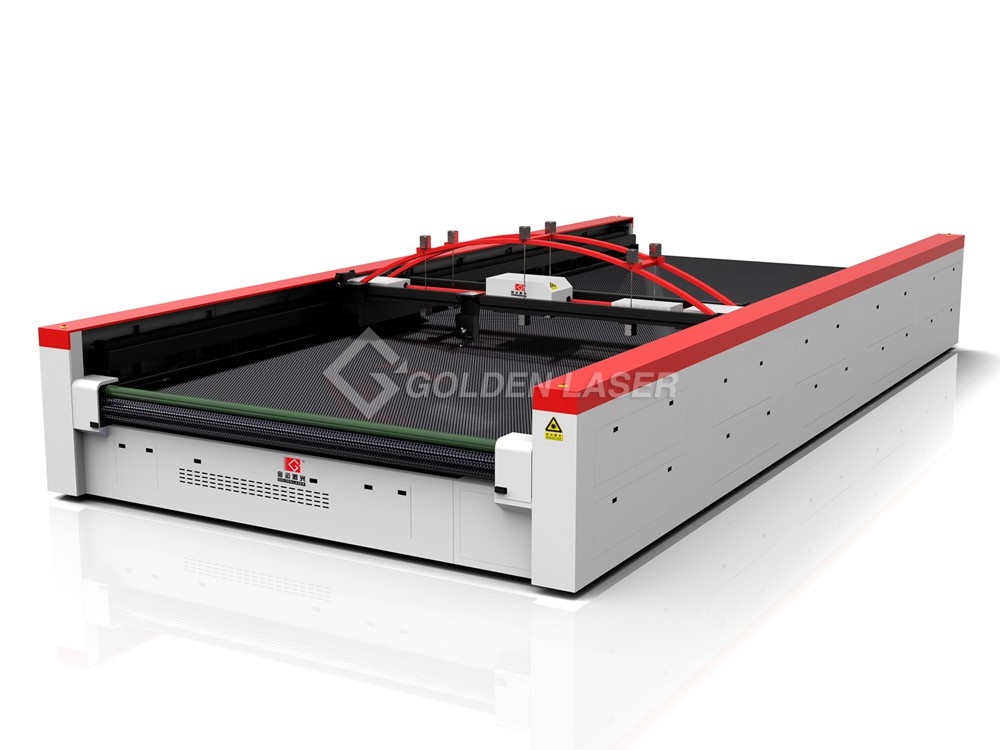

Model No.: CJG-320800LD

Introduction:

- Large format flatbed laser cutter with working area 126″ x 315″ (3,200mm x 8,000mm).

- It is designed for the laser cutting of extremely large textiles directly from the roll.

- Smooth and clean cutting edges, no reworking necessary.

- Automated production process with conveyor and feeding systems.

- Complete extraction and filtering of the cutting emissions.

Features of the Laser Cutter Machine

Technical Specifications

| Laser type | CO2 glass laser tube / CO2 RF metal laser tube |

| Laser power | 150W / 300W |

| Working area | 3200mm x 8000mm (126" x 315") |

| Maximum material width | 3200mm (126") |

| Working table | Vacuum conveyor working table |

| Mechanical System | Servo motor; Gear and rack driven |

| Cutting speed | 0~500mm/s |

| Acceleration | 5000mm/s2 |

| Power supply | AC220V±5% 50/60Hz |

| Graphic Format Supported | AI, PLT, DXF, BMP, DST |

※ Working areas and laser power can be customized on request. Laser system configurations tailored to your applications are available.

Options

Customized optional extras simplify your production and increase your possibilities

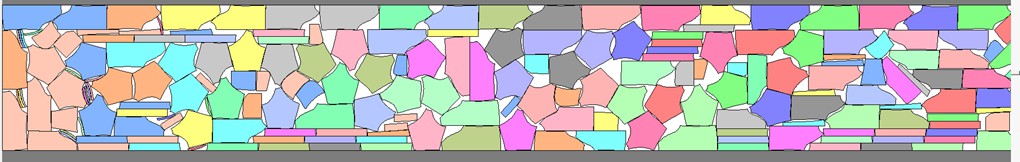

Nesting Software

Automated Software to make your workflow even more efficient

Goldenlaser’s Auto Maker Software will help to deliver fast with uncompromised quality. With the help of our nesting software, your cutting files will perfectly be placed on the material. You will optimize the exploitation of your area and minimize your material consumption with the powerful nesting module.

Technical Specifications

| Laser type | CO2 glass laser tube / CO2 RF metal laser tube |

| Laser power | 150W / 300W |

| Working area | 3200mm x 8000mm (126″ x 315″) |

| Maximum material width | 3200mm (126″) |

| Working table | Vacuum conveyor working table |

| Mechanical System | Servo motor; Gear and rack driven |

| Cutting speed | 0~500mm/s |

| Acceleration | 5000mm/s2 |

| Power supply | AC220V±5% 50/60Hz |

| Graphic Format Supported | AI, PLT, DXF, BMP, DST |

※ Working areas and laser power can be customized on request. Laser system configurations tailored to your applications are available.

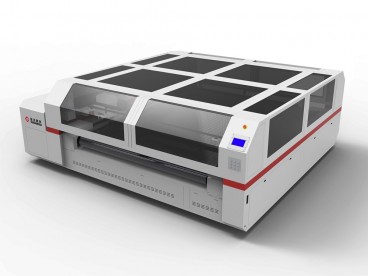

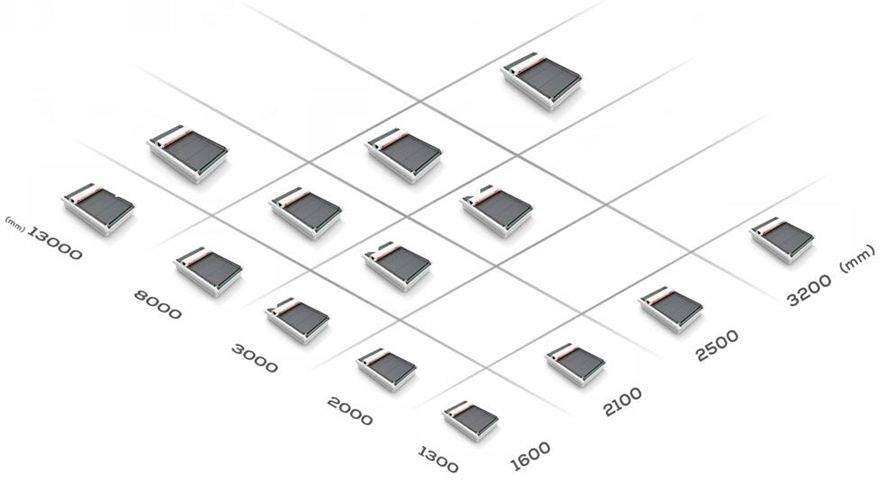

GOLDENLASER CO2 Flatbed Laser Cutting Systems

Working areas: 1600mm × 2000mm (63″ × 79″), 1600mm × 3000mm (63″ × 118″), 2300mm × 2300mm (90.5″ × 90.5″), 2500mm × 3000mm (98.4″×118″), 3000mm × 3000mm (118″ × 118″), 3500mm × 4000mm (137.7″ × 157.4″), 3200mm x 8000mm (126″ x 315″)

***The cutting area can be customized according to different applications.***

Application

Suitable for cutting technical textile, polyester, nylon, cotton, PE / ETFE / Oxford fabric, polyamide fabric, PU / AC coated fabric, canvas, etc.

This large format flatbed laser cutter is mainly used to cut textiles of outdoor products, such as tents, marquee, inflatable products, sailcloth, parachute, paraglider, parasail, canopy, awning, surf kites, fire balloon, etc.

Please contact GOLDEN LASER for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp…)?