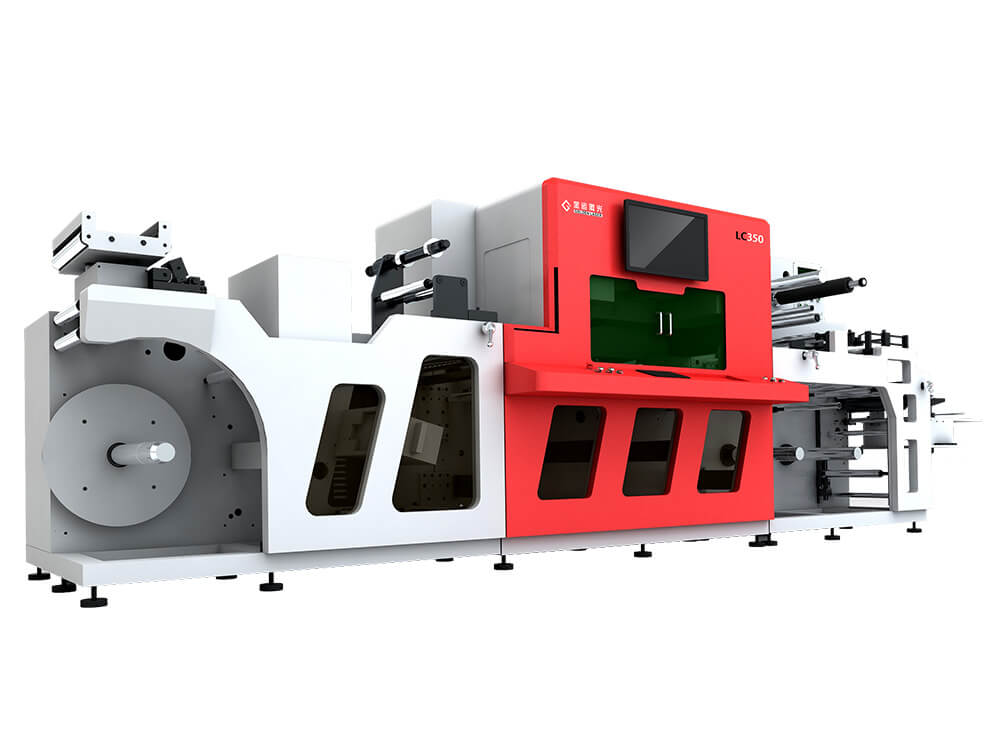

Laser Die Cutting Machine

Improve your die-cutting capabilities with a laser cutting machine

Goldenlaser is the first laser application solution provider in China to develop and apply laser technology in self-adhesive label die-cutting. Over 200 laser die-cutting machines installed in 30 countries over the past 20 years, and the knowledge gained during this time combined with market feedback has led to the further development and optimization of our laser die-cutting machines.

Our clients have benefited from its enhanced capabilities. Now is the time to perform laser die cutting as a way to provide your business an advantage over your competitors.

Machine Recommendation

Technical specifications of goldenlaser's two standard models of laser die-cutting machines

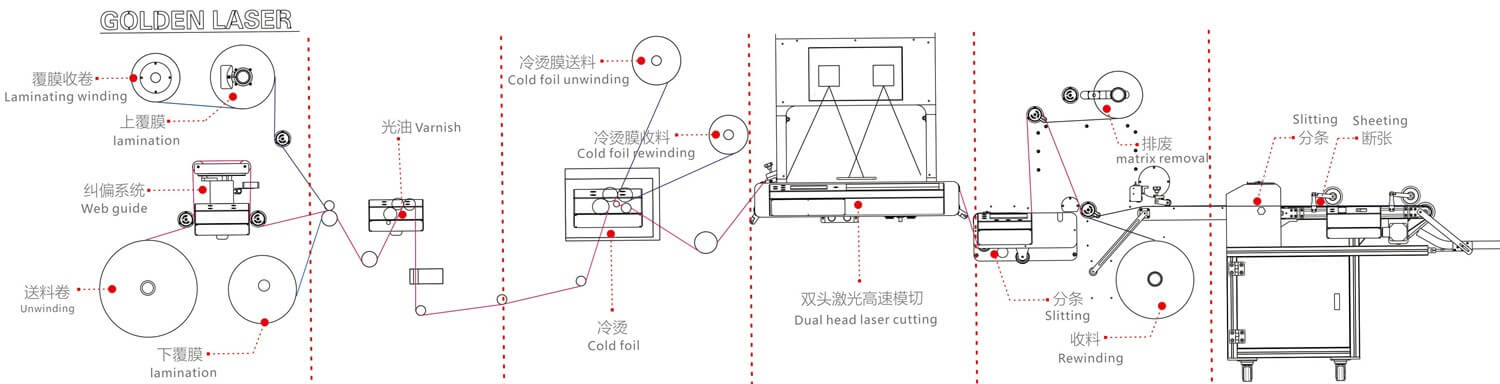

Modular Design

Custom solutions available for the most challenging converting applications & requirements

Configurations and options

Unwinder with closed-loop tension control

Max unwinder diameter: 750mm

Electronic web guide with ultrasonic edge guide sensor

With two pneumatic shafts and unwind/rewind

Dual lasers station. Can be equipped with one or two laser scan heads. (Three or more laser heads can be customized)

Optional shear slitter or razor blade slitter

Dual rewinder. With closed-loop tension control system ensures continuous stable tension. 750 mm maximum rewind diameter.

Laser Die Cutting Machine Benefits

Laser Cutting Technology

Ideal solution for just-in-time manufacturing, short-medium production runs & complex geometry. Eliminates traditional hard tooling & die fabrication, maintenance and storage.

PC Workstation & Software

Through the PC you can manage all the parameters of the laser station, optimize layout for maximum web speed & yields, convert graphics files to be cut & reload jobs and all parameters in seconds.

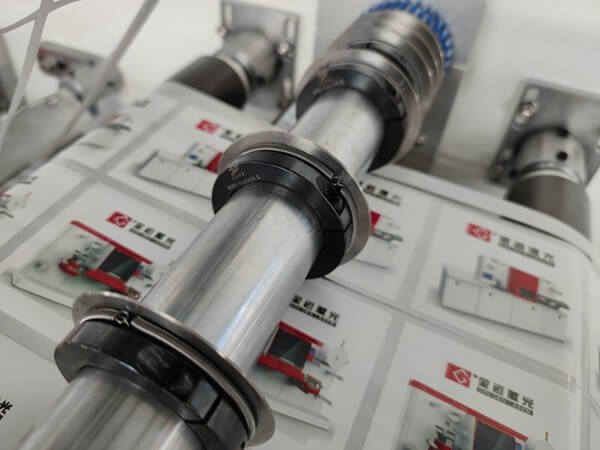

Encoder Control

Encoder to control the exact feeding, speed & positioning of the material

Rapid Processing Speeds

Full cut, kiss-cut, engrave-mark & score cut the web in continuous, start-stop or tracking version (cuts longer than cutting area) with web speeds up to 120 meters per minute.

Modular Design - Extreme Flexibility

A variety of options are available to automate and customize the system to suit a wide variety of converting requirements. Most options can be added in the future.

Variety of Power & Work Areas

Wide variety of laser powers available from 150, 300 to 600 Watts and work areas from 230mm x 230mm, 350mm x 350mm up to customized working area 700mm x 700mm.

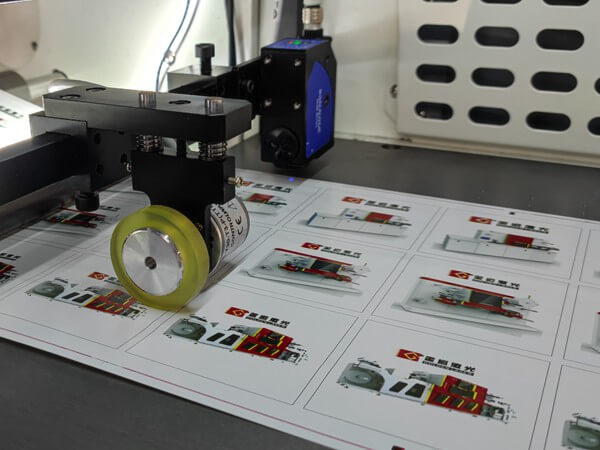

Precision Cutting

Produce simple or complex geometry not achieveable with rotary die cutting tools. Superior part quality that cannot be replicated in the traditional die cutting process.

Vision System - Cut to Print

Allows precision cutting with cut-print registration of 0.1mm. Various vision (registration) systems are availabile for registering printed materials or pre-die cut shapes.

Low Operating Costs

High through-put, elimination of hard tooling & improved material yields equal increased profit margins.

Application

The typical sectors and applicable materials for our laser die cutting machines

The main sectors for our laser die cutting machines include:

Labels, stickers, self-adhesive tapes, printing & packaging, 3M, industrial, automotive, aerospace, electronics, abrasives, gaskets, composites, medical, stencils, twills, patches & embellishments for apparel, etc.

The main materials for our laser die cutting machines can cut:

PET, paper, coated paper, glossy paper, matte paper, synthetic paper, kraft paper, polypropylene (PP), TPU, BOPP, plastic, reflective film, heat transfer vinyl, film, PET film, microfinishing film, lapping film, double-sided tape, VHB tape, reflex tape, fabric, Mylar stencils, etc.

Laser Cutting Samples

The real samples tested by our laser die cutting machines

Video

Watch laser die-cutting machines for an array of sectors in action

Dual Head Laser Cutting Machine for Printed Labels

Roll-to-Part Laser Cutter for Sticker

Roll to Sheet Laser Die-Cutter for Heat Transfer Film

Roll to Sheet Laser Cutting of 3M VHB Double-sided Tape

Laser Cutting Double Sided Tape for FPC Lamp of Glue

Roll to Roll Laser Cutting of Battery Separator Film

FAQ

Frequently Asked Questions on Laser Die Cutting Machine

Laser cutting system is contactless type cutting system using laser beam. Unlike other light, due to low scattering rate and high linearity, laser can concentrate large energy on small area. This concentrated energy is adjusted to desired location and cuts label media.

One of benefits of laser cutting is to get equally high quality of output from repeated works. When using knife, abrasion of knife changes quality of cutting, but laser guarantees consistency of power for 10,000 hours, which lead to equal quality for label.

In addition, Goldenlaser provide even more accurate cutting by calibrating cutting location via encoder, mark sensor and vision system.

LC350 & LC230 supports various types of materials including label stock, paper, PET, PP, BOPP, heat transfer film, reflective material, PSA, double sided adhesives, gaskets, plastics, textiles, difficult abrasive materials & even aggressive adhesive materials like VHB.

Yes. You can set up different cutting conditions for each layer using the software.

It enables various cutting operation by adjusting strength and speed of laser.

Up to 370mm wide roll can be mounted in LC350.

Up to 240mm wide roll can be mounted in LC230.

Max web speed is 120m/min. It is recommended that you measure speed in hand by cutting samples as the result may vary depending on laser power, type of material, and cut pattern.

Max diameter of roll is supported up to 750mm

LC350 & LC230 requires fume extractor to eliminate smoke during cutting and air compressor to remove dust resided on paper. It is important to have right peripherals for work environment in order to maintain the laser die cutters in the best condition.