A na u na le lipotso kapa ho na le litaba tsa tekheniki tseo u ka ratang ho li bua?Haeba ho joalo, u amohelehile haholo ho ikopanya le rona!Ka kopo, tlatsa foromo e ka tlase.Litsebi tsa rona li lula li thabela ho re thusa 'me li tla khutlela ho uena hang-hang.

Laser Cutting ea Synthetic Textiles

Ho sebetsa ka laser ho fumaneha ka masela a maiketsetso:

1. Ho itšeha ka laser

Matla a lebone la laser la CO2 a monngoa habonolo ke lesela la maiketsetso.Ha matla a laser a phahame ka ho lekaneng, a tla khaola lesela ka ho feletseng.Ha u seha ka laser, masela a mangata a maiketsetso a fetoha mouoane ka potlako, 'me a fella ka mahlakoreng a hloekileng, a boreleli a nang le libaka tse fokolang tse amehang mocheso.

2. Ho ngola ka laser (ho tšoaea ka laser)

Matla a lebone la laser la CO2 a ka laoloa e le hore a tlose (ho ngola) thepa ka botebo bo itseng.Mokhoa oa ho ngola ka laser o ka sebelisoa ho etsa lipaterone le meralo e rarahaneng holim'a masela a maiketsetso.

3. Ho phatloha ka laser

CO2 laser e khona ho phunya masoba a manyane le a nepahetseng maselang a maiketsetso.Ha ho bapisoa le ho phunyeha ha mechine, laser e fana ka lebelo, ho tenyetseha, tharollo le ho nepahala.Laser perforation ea masela e makhethe ebile e hloekile, e na le botsitso bo botle ebile ha e na ts'ebetso e latelang.

Melemo ea ho seha masela a maiketsetso a sebelisa lasers:

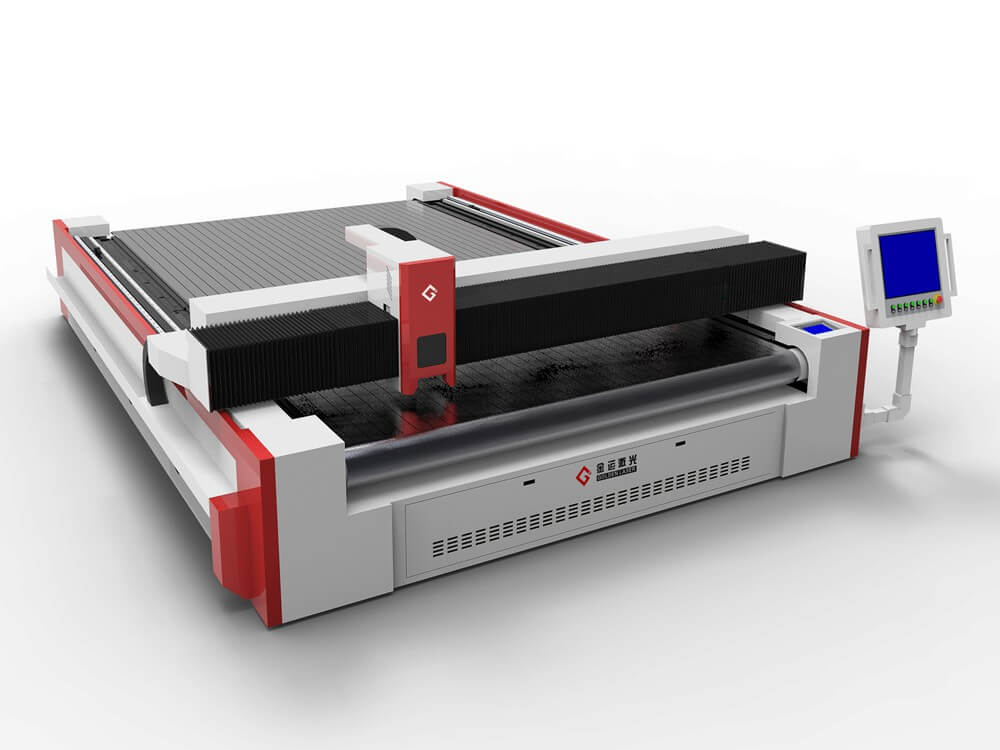

Melemo ea mochini o sehang oa laser oa khauta bakeng sa lesela:

Tlhahisoleseding ea thepa bakeng sa ho itšeha ka laser ea masela a maiketsetso:

Li-synthetic fibers li entsoe ka li-polymer tse entsoeng tse thehiloeng ho lisebelisoa tse tala tse kang petroleum.Mefuta e fapaneng ea likhoele e hlahisoa ka metsoako e mengata e fapaneng ea lik'hemik'hale.Fiber e 'ngoe le e' ngoe ea maiketsetso e na le thepa le litšoaneleho tse ikhethang tse lumellanang le lits'ebetso tse ikhethileng.Likhoele tse 'nè tsa maiketsetso -polyester, polyamide (nylon), acrylic le polyolefin - li laola 'maraka oa masela.Masela a maiketsetso a sebelisoa indastering le makaleng a fapaneng a fapaneng, ho kenyelletsa, liaparo, thepa ea ka tlung, filtration, likoloi, sefofane, marine, jj.

Hangata masela a maiketsetso a entsoe ka polasetiki, joalo ka polyester, e arabelang hantle ts'ebetsong ea laser.Lebone la laser le qhibilihisa masela ana ka mokhoa o laolehileng, e leng se etsang hore ho be le mapheo a se nang burr le a tiisitsoeng.