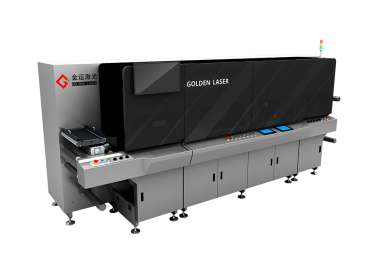

Mirgine-zuwa-Roll da Mirgine-zuwa-Sashe Laser Die Yankan Machine

Na'urar Samfura: LC350F/LC520F

Gabatarwa:

Tsarin Laser Die-Cutting na Hybrid Laser na iya canzawa ba tare da ɓata lokaci ba tsakanin mirgine-zuwa-mirgina da mirgina-zuwa-bangaren samarwa, yana ba da sassaucin ra'ayi a cikin sarrafa alamar naɗaɗɗen bayanai dalla-dalla. Yana ba da damar aiki mai sauri mai sauri, sauƙin sarrafa umarni iri-iri da saduwa da buƙatun samar da lakabi iri-iri.

Hybrid Digital Laser Die-Cutting System

M & Inganci, Ƙarfafa Ƙirƙirar Label mai Layi

The Hybrid Digital Laser Die-Cutting System ci-gaba ne, ƙwararren bayani wanda aka tsara musamman don masana'antar sarrafa tambarin zamani. Haɗa duka biyunMirgine-zuwa-RollkumaMirgine-zuwa-Kashihanyoyin samarwa, wannan tsarin cikin sauƙin dacewa da buƙatun sarrafawa iri-iri. Ta yin amfani da fasaha na yankan Laser mai mahimmanci, yana kawar da buƙatar mutuwar gargajiya, yana ba da damar canje-canjen aiki mara kyau da kuma samar da sassauƙa. Wannan mahimmanci yana haɓaka duka inganci da ingancin samfur.

Ko don samarwa mai girma ko ƙananan tsari, umarni na musamman iri-iri, wannan tsarin yana ba da kyakkyawan aiki, yana taimaka wa kasuwancin su kasance masu gasa a zamanin masana'antu masu wayo.

Mabuɗin Siffofin

Tsarin yana goyan bayan hanyoyin yankan Roll-to-Roll da Roll-to-Part, yana ba da damar daidaitawa da sauri zuwa nau'ikan ayyuka daban-daban. Canjawa tsakanin hanyoyin samarwa yana da sauri kuma baya buƙatar gyare-gyare masu rikitarwa, yana rage lokacin saiti sosai. Wannan yana ba da damar sauye-sauye marasa daidaituwa tsakanin umarni daban-daban kuma yana haɓaka sassauƙar samarwa gabaɗaya.

An sanye shi da shirin sarrafawa mai hankali, tsarin yana gane bukatun sarrafawa ta atomatik kuma yana daidaitawa zuwa yanayin yanke da ya dace. Ƙwararren mai amfani da shi yana sauƙaƙa aiki, har ma ga masu farawa, yana rage buƙatar ƙwararrun ƙwararrun aiki. Yin aiki da kai a cikin tsarin yana haɓaka haɓaka aiki kuma yana taimakawa masana'antu samun haɓaka haɓaka masana'antu na dijital da fasaha.

Ƙaddamar da tushen laser mai girma da kuma tsarin kula da motsi na ci gaba, na'urar tana tabbatar da daidaito tsakanin sauri da daidaito. Yana goyan bayan babban saurin ci gaba da aiki tare da tsabta, santsi yankan gefuna, isar da barga da ingantaccen inganci don saduwa da ƙa'idodi masu buƙata na samfuran lakabin ƙima.

Dijital Laser mutu-yanke gusar da bukatar gargajiya yankan mutu, rage kayan aiki halin kaka da kuma kiyaye kudi. Hakanan yana rage raguwar lokaci saboda canjin kayan aiki, inganta sassaucin samarwa da rage yawan farashin aiki.

Tsarin kyamara wanda:

•Gano Alamomin Rijista: Yana tabbatar da daidaitaccen jeri na yankan Laser tare da ƙirar da aka riga aka buga.

•Duban lahani: Yana gano lahani a cikin kayan ko tsarin yanke.

•gyare-gyare na atomatik: Yana daidaita hanyar laser ta atomatik don rama bambancin kayan aiki ko bugu.

Tsarin yana aiki tare da kayan lakabi iri-iri, gami da PET, PP, takarda, kaset na 3M VHB, da fina-finai na holographic. Ana amfani da shi sosai a masana'antu kamar abinci da abin sha, kayan kwalliya, magunguna, kayan lantarki, dabaru, da lakabin tsaro. Ko sarrafa alamun al'ada ko hadaddun, sifofi na al'ada, yana tabbatar da sauri, madaidaicin sakamako.

Laser Die Yankan Fa'idodi Akan Yankan Mutuwar Gargajiya:

| Saukewa: LC350F | Saukewa: LC520F | |

| Mafi Girman Yanar Gizo | mm 350 | mm 520 |

| Ƙarfin Laser | 30W / 60W / 100W / 150W / 200W / 300W / 600W | |

| Laser Head | Single Laser shugaban / Multiple Laser shugabannin | |

| Yanke Daidaito | ± 0.1mm | |

| Tushen wutan lantarki | 380V 50/60Hz Mataki na uku | |

| Girman Injin | 4.6m×1.5m×1.75m | /4.8m×1.6m×1.88m |

Golden Laser Die-Yanke Machine Model Takaitaccen

| Nau'in Mirgine-zuwa-Roll | |

| Standard Digital Laser Die Cutter tare da Aikin Sheeting | Saukewa: LC350/LC520 |

| Hybrid Digital Laser Die Cutter (Mirgine don mirgine kuma Mirgine zuwa takarda) | Saukewa: LC350F/LC520F |

| Dijital Laser Die Cutter don Lambobin Launi na Ƙarshen Ƙarshe | Saukewa: LC350B/LC520B |

| Multi-tashar Laser Die Cutter | Saukewa: LC800 |

| MicroLab Digital Laser Die Cutter | Saukewa: LC3550JG |

| Nau'in Sheet-Fed | |

| Sheet Fed Laser Die Cutter | LC1050/LC8060/LC5035 |

| Domin Fim da Yankan Kaset | |

| Laser Die Cutter don Fim da Tef | Saukewa: LC350/LC1250 |

| Nau'in Laser Die Cutter don Fim da Tef | Saukewa: LC250 |

| Yankan Sheet | |

| Babban Madaidaicin Laser Cutter | Saukewa: JMS2TJG5050DT-M |

Kayayyaki:

Waɗannan injina suna iya ɗaukar abubuwa masu sassauƙa iri-iri, gami da:

- • Takarda: Takamaimai, kwali, marufi.

- • Fina-finai: PET, BOPP, PP, Polyimide (Kapton), da dai sauransu Ana amfani da su don lakabi, da'irori masu sassauƙa, da marufi.

- • Adhesives: kaset, lakabi, ƙaya.

- • Yadudduka: Yadudduka masu saƙa da waɗanda ba saƙa.

- • Fassara:

- • Laminates: Multi-layered kayan.

Aikace-aikace:

- • Takamaimai: Samar da alamomi masu siffa na al'ada tare da ƙira mai ƙima.

- • Marufi: Ƙirƙirar marufi na al'ada da kuma girma.

- • Kayan Lantarki: Ƙirƙirar da'irori masu sassauƙa, abubuwan da aka haɗa don firikwensin.

- • Na'urorin likitanci: Yanke kayan don facin likita, na'urori.

- • Motoci: Abubuwan masana'anta don datsa ciki, alamu.

- • Tufafi: Yanke alamu na tufafi, kayan ado.

- • Jirgin sama: Yanke kayan don abubuwan haɗin jirgin.

- • Samfura: da sauri ƙirƙirar samfuran sabbin ƙira.

Da fatan za a tuntuɓi goldenlaser don ƙarin bayani. Amsar ku na tambayoyi masu zuwa za su taimake mu bayar da shawarar injin da ya fi dacewa.

1. Menene babban abin da ake buƙata na sarrafa ku? Laser yankan ko Laser engraving (alama) ko Laser perforating?

2. Wani abu kuke buƙatar aiwatar da laser?

3. Menene girman da kauri na kayan?

4. Bayan sarrafa Laser, menene za a yi amfani da kayan aiki? (Masana'antar aikace-aikacen) / Menene samfurin ku na ƙarshe?

5. Sunan kamfanin ku, gidan yanar gizonku, imel, Tel (WhatsApp / WeChat)?