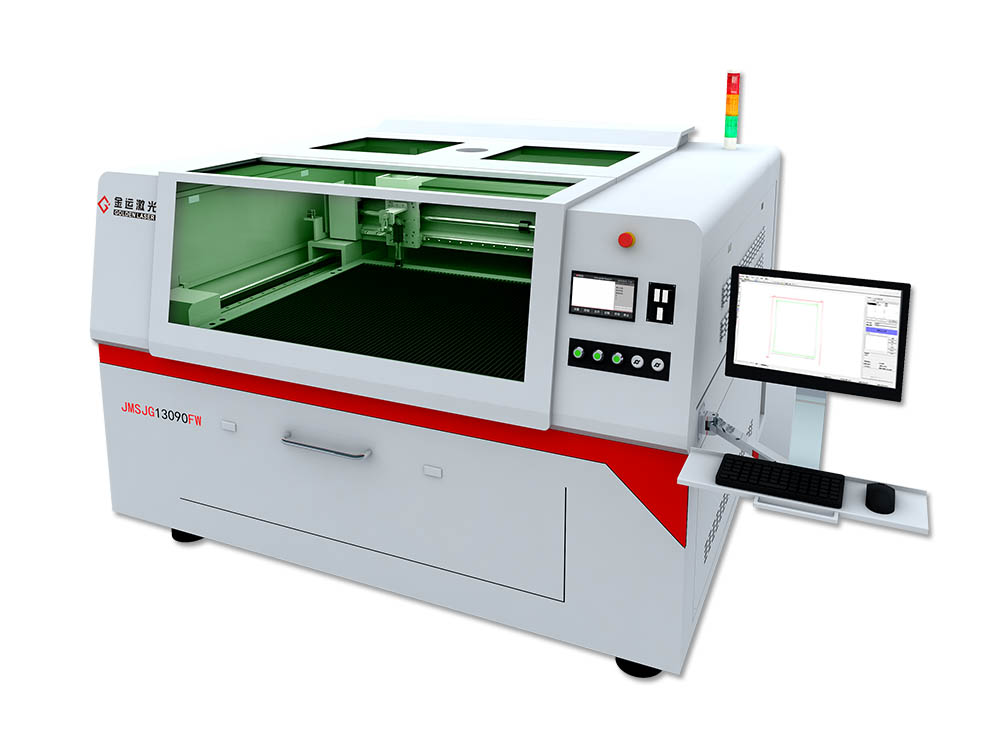

High Precision CO2 Laser Cutting Machine

Model No.: JMSJG Series

Introduction:

This high precision CO₂ laser cutting machine with a marble working platform ensures a high degree of stability in the operation of the machine. Precision screw and full servo motor drive ensure high precision and high speed cutting. Self-developed vision camera system for cutting printed materials.

Machine Features

Machine structure

The machine adopts a fully enclosed design with front and rear flap doors or left and right moving doors to ensure operational safety and a working environment free from laser fume pollution.

Machine base frame

Steel welded base frame, ageing treatment, high precision CNC machine tool machining. The mounting surface of the guide rails is finished in cast iron to ensure the accuracy of the mounting of the motion system.

Processing mode

The laser generator is fixed; the cutting head is precisely moved by the X-Y axis gantry, and the laser beam is vertical to the surface of the raw material.

Motion control

The closed-loop multi-axis motion control system independently developed by GOLDENLASER can adjust the rotation angle of the servo motor according to the feedback data of the magnetic scale; it supports the docking of vision and MES systems.

Machine Advantages

Specifications

| Laser type | CO2 glass laser / RF metal laser |

| Laser power | 30W ~ 300W |

| Working area | 500x500mm, 600x600mm, 1000x100mm, 1300x900mm, 1400x800mm |

| X-Y axis transmission | Precision screw + linear guide |

| X-Y axis drive | Servo motor |

| Repositioning Accuracy | ±0.01mm |

| Cutting accuracy | ±0.05mm |

| Power supply | Single-phase 220V, 35A, 50Hz |

| Graphic format supported | PLT, DXF, AI, DST, BMP |

Software Advantages

• Easy to operate, user-friendly working interface.

• Offline and online interchangeable at any time.

• Applicable to Windows-compatible software such as CorelDRAW, CAD, Photoshop, Word, Excel, etc., print output directly without conversion.

• The software is compatible with AI, BMP, PLT, DXF, DST graphic formats.

• Capable of multi-level layered processing and defined output sequences.

• Various path optimization functions, pause function during machining.

• Various ways of saving graphics and machining parameters and their reuse.

• Processing time estimation and cost budgeting functions.

• The starting point, working path and laser head stopping position can be set according to the different needs of the process.

• Real-time speed adjustment during processing.

• Power failure protection function. If the power is suddenly cut off during machining, the system can remember the break point and quickly find it when the power is restored and continue machining.

• Individual settings for process and accuracy, laser head trajectory simulation for easy visualisation of the cutting sequence.

• Remote assistance function for troubleshooting and training remotely using the internet.

Application Industry

• Membrane switches and keypads

• Flexible conductive electronics

• EMI, RFI, ESD shielding

• Graphic overlays

• Front panel, control panel

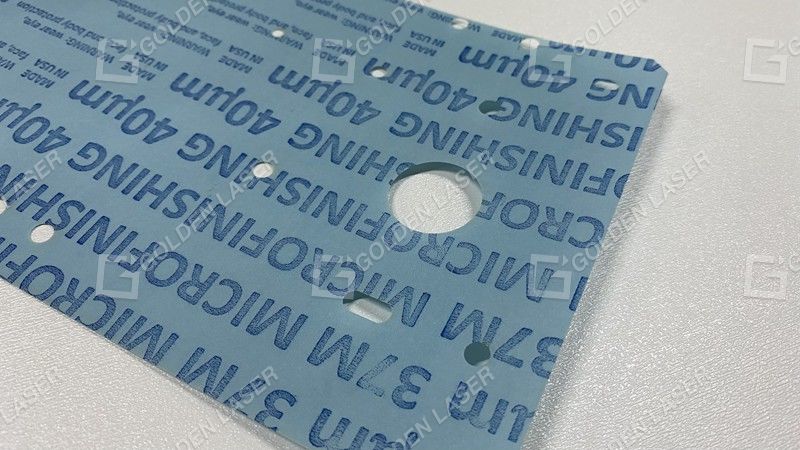

• Industrial labels, 3M tapes

• Gaskets, spacers, seals and insulators

• Foils for the automotive industry

• Protective film

• Adhesive tape

• Printed functional foil

• Plastic film, PET film

• Polyester, polycarbonate or polyethylene foil

• Electronic paper

Laser Cutting Samples

Watch High Precision CO2 Laser Cutting in Action!

High Precision CO2 Laser Cutting Machine for Membrane Panel

Main Technical Parameters

| Laser type | CO2 glass laser / CO2 RF metal laser |

| Laser power | 30W ~ 300W |

| Working table | Aluminum alloy negative pressure working table |

| Working area | 500x500mm / 600x600mm /1000x800mm / 1300x900mm / 1400x800mm |

| Machine body structure | Welded base frame (ageing treatment + finishing), closed machining area |

| X-Y axis transmission | Precision screw + linear guide |

| X-Y axis drive | Servo motor drive |

| Platform flatness | ≤80um |

| Processing speed | 0-500mm/s |

| Acceleration | 0-3500mm/s² |

| Repositioning Accuracy | ±0.01mm |

| Cutting accuracy | ±0.05mm |

| Optical structure | Flying optical path structure |

| Control system | GOLDENLASER multi-axis closed-loop control system |

| Camera | 1.3 megapixel industrial camera |

| Recognition mode | Mark registration |

| Graphic formats supported | AI, BMP, PLT, DXF, DST, etc. |

| Power supply | Single-phase 220V, 35A, 50Hz |

| Other options | Honeycomb / knife strip work table, roll-to-roll structure cutting system |

Golden Laser High Precision CO2 Laser Cutting Machine Series Models

| Model No. | Working Area |

| JMSJG-5050 | 500x500mm (19.6”x19.6”) |

| JMSJG-6060 | 600x600mm (23.6”x23.6”) |

| JMSJG-10010 | 1000x1000mm (39.3”x39.3”) |

| JMSJG-13090 | 1300x900mm (51.1”x35.4”) |

| JMSJG-14080 | 1400x800mm (55.1”x31.5”) |

Application Sectors

Membrane switches and keypads, Flexible conductive electronics, EMI, RFI, ESD shielding, Graphic overlays, Front panel, control panel, Industrial labels, 3M tapes, Gaskets, spacers, seals and insulators, foils for the automotive industry, etc.

- Protective film

- Adhesive tape

- Printed functional foil

- Plastic film, PET film

- Polyester, polycarbonate or polyethylene foil

- Electronic paper

Please contact goldenlaser for further information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (laser marking) or laser perforating?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product (application industry)?