Just using GOLDENLASER Systems and enjoying your production.

Automatic Laser Cutter with CCD Camera and Roll Feeder

Model No.: ZDJG-3020LD

Introduction:

- CO2 Laser power from 65 watts to 150 watts

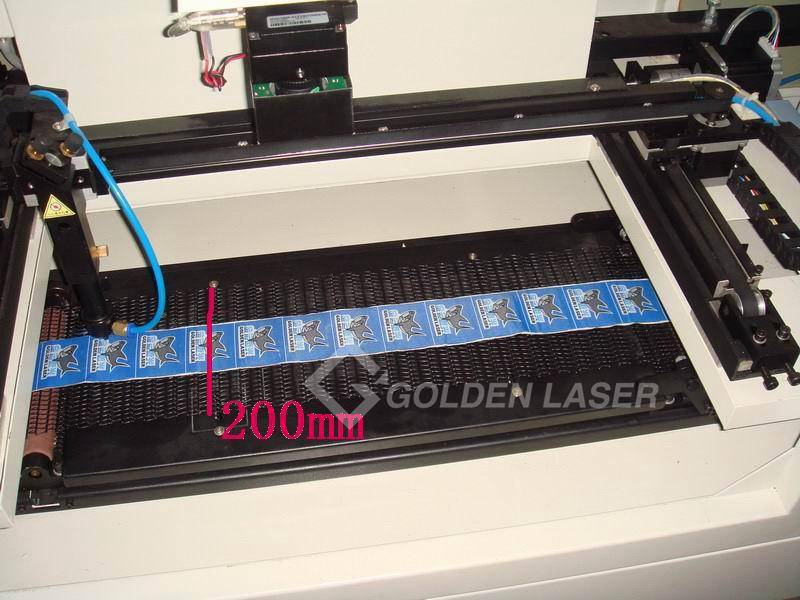

- Suitable for cutting ribbons and labels in roll of the width within 200mm

- Full cutting from the roll to pieces

- CCD camera to recognize the label shapes

- Conveyor working table and roll feeder – Automatic and continuous processing

Specifications

Main Technical Specifications of ZDJG-3020LD CCD Camera Laser Cutter

| Laser Type | CO2 DC glass laser tube |

| Laser Power | 65W / 80W / 110W / 130W / 150W |

| Working Area | 300mm×200mm |

| Working Table | Conveyor working table |

| Positioning Accuracy | ±0.1mm |

| Motion System | Step motor |

| Cooling System | Constant temperature water chiller |

| Exhaust System | 550W or 1100W Exhaust system |

| Air Blowing | Mini air compressor |

| Power Supply | AC220V±5% 50/60Hz |

| Graphic Format Supported | PLT, DXF, AI, BMP, DST |

Machine Features

Laser Cutting Benefits

Applicable Materials and Industries

Suitable for woven label, embroidered label, printed label, Velcro, ribbon, webbing, etc.

Natural and synthetic fabrics, polyester, nylon, leather, paper, etc.

Applicable to clothing labels and clothing accessories production.

Some Laser Cutting Samples

We are always bringing you simple, fast, individualized and cost-effective laser processing solutions.

Technical Parameters

| Model NO. | ZDJG3020LD |

| Laser Type | CO2 DC glass laser tube |

| Laser Power | 65W 80W 110W 130W 150W |

| Working Area | 300mm×200mm |

| Working Table | Conveyor working table |

| Positioning Accuracy | ±0.1mm |

| Motion System | Step motor |

| Cooling System | Constant temperature water chiller |

| Exhaust System | 550W or 1100W Exhaust system |

| Air Blowing | Mini air compressor |

| Power Supply | AC220V±5% 50/60Hz |

| Graphic Format Supported | PLT, DXF, AI, BMP, DST |

| External Dimensions | 1760mm(L)×740mm(W)×1390mm(H) |

| Net Weight | 205KG |

*** Note: As products are constantly updated, please contact us for the latest specifications. ***

GOLDENLASER MARS Series Laser Systems Summary

1. Laser Cutting Machines with CCD Camera

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

2. Laser Cutting Machines with Conveyor Belt

| Model No. |

Laser head |

Working area |

| MJG-160100LD |

One head |

1600mm×1000mm |

| MJGHY-160100LD II |

Dual head |

|

| MJG-14090LD |

One head |

1400mm×900mm |

| MJGHY-14090D II |

Dual head |

|

| MJG-180100LD |

One head |

1800mm×1000mm |

| MJGHY-180100 II |

Dual head |

|

| JGHY-16580 IV |

Four head |

1650mm×800mm |

3. Laser Cutting Engraving Machines with Honeycomb Working Table

| Model No. |

Laser head |

Working area |

| JG-10060 |

One head |

1000mm×600mm |

| JG-13070 |

One head |

1300mm×700mm |

| JGHY-12570 II |

Dual head |

1250mm×700mm |

| JG-13090 |

One head |

1300mm×900mm |

| MJG-14090 |

One head |

1400mm×900mm |

| MJGHY-14090 II |

Dual head |

|

| MJG-160100 |

One head |

1600mm×1000mm |

| MJGHY-160100 II |

Dual head |

|

| MJG-180100 |

One head |

1800mm×1000mm |

| MJGHY-180100 II |

Dual head |

4. Laser Cutting Engraving Machines with Table Lifting System

| Model No. |

Laser head |

Working area |

| JG-10060SG |

One head |

1000mm×600mm |

| JG-13090SG |

1300mm×900mm |

Applicable materials and industries

Suitable for woven label, embroidered label, printed label, Velcro, ribbon, webbing, etc.

Natural and synthetic fabrics, polyester, nylon, leather, paper, fiberglass, Aramid, etc.

Applicable to clothing labels and clothing accessories production.

Laser Cutting Samples

Please contact goldenlaser for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application industry) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp / WeChat)?