Dual CNC Fiber Laser Sheet Metal lan Tube / Mesin Cutting Pipa

Model Nomer: GF-1530T

Pambuka:

- dawa proses tabung:iki 6m

- diameteripun tabung proses:20mm nganti 200mm

- format sheet metal:1,5×3m, 1,5×4m, 1,5×6m, 2×4m, 2×6m

- sumber serat laser:700W ~ 3000W

- bahan mesin:baja ringan, baja tahan karat, aluminium, tembaga, kuningan, baja galvanis

Kaluwihan saka mesin nglereni laser serat

konsumsi daya kurang

Konsumsi daya laser serat mung 20% ~ 30% saka laser CO2. Efisiensi listrik laser serat sing tambah akeh nyuda konsumsi daya sistem laser serat, ngirit biaya listrik lan nyuda investasi awal ing peralatan listrik.

Cepet Cepet

Efisiensi laser serat ngluwihi laser YAG utawa CO2. Pemotongan laser serat saka logam tipis kaping pindho luwih cepet tinimbang pemotongan laser YAG utawa CO2: baja karbon lan baja tahan karat nganti 8 mm (0.31") minangka logam sing biasane entuk manfaat saka teknologi laser serat.

Pangopènan gratis

Umur sing digambarake saka laser serat luwih saka 100.000 jam operasi terus-terusan utawa pulsa. Laser serat ora mbutuhake pangopènan rutin. Ora ana gas laser sing dibutuhake. Kualitas sinar laser stabil saka wektu lan langsung kasedhiya nalika wiwitan.

Gampang kanggo Cut logam reflektif

Sinar laser serat bisa nglereni logam reflektif kanthi energi sing luwih murah amarga laser diserap menyang logam sing dipotong. Tembaga, kuningan, aluminium lan baja galvanis bisa gampang dipotong kanthi laser serat, kajaba baja ringan lan baja tahan karat.

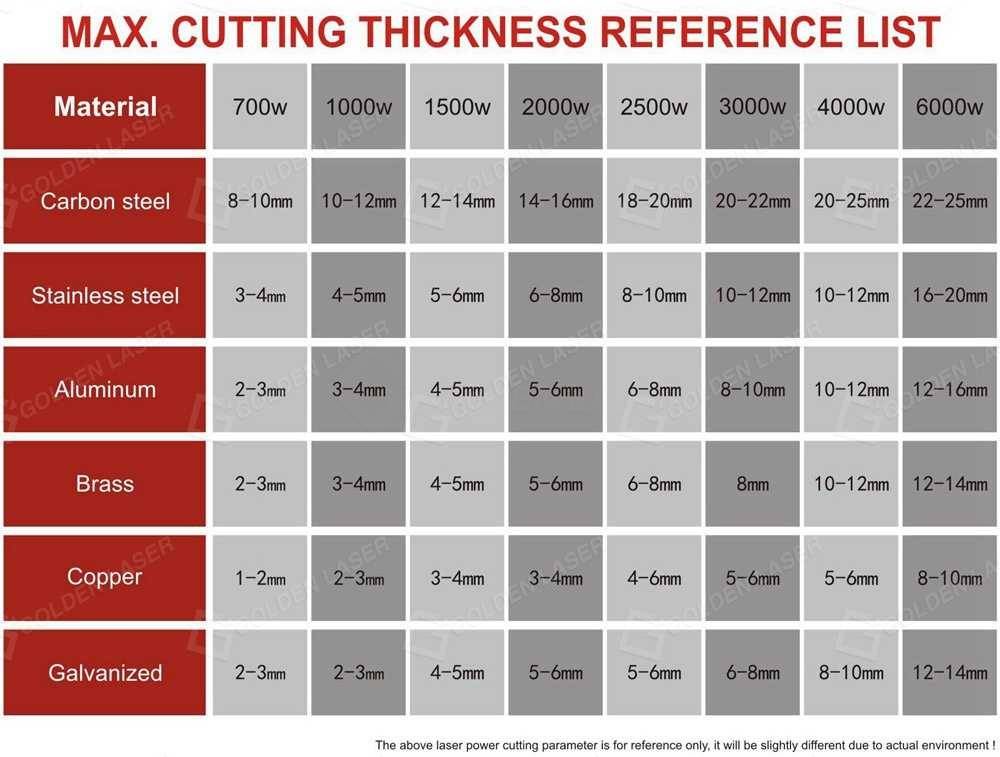

Kekandelan nglereni maksimal kanggo macem-macem kekuwatan laser

Dual CNC Fiber Laser Sheet Metal lan Tube / Mesin Cutting Pipa

Parameter teknis

| Model No. | GF-1530T |

| jinis laser | Laser serat (nLight / IPG) |

| Panjang gelombang laser | 1070nm |

| Rating output daya laser | 700W 1000W 1200W 1500W 2000W 2500W 3000W |

| Meja kerja | Tabel kerja tetep |

| Area kerja kanggo pangolahan lembaran (L × W) | 1500mm × 3000mm |

| Pengolahan Pipa/Tabung (L×Φ) | L3000mm, Φ20~200mm (Φ20~300mm kanggo pilihan) |

| Akurasi posisi poros X, Y lan Z | ± 0.03mm/m |

| Baleni akurasi posisi poros X, Y lan Z | ± 0,02 mm |

| Kacepetan posisi maksimal poros X lan Y | 72m/min |

| Akselerasi | 1g |

| Sistem kontrol | CYPCUT |

| Format didhukung | AI, BMP, PLT, DXF, DST, lsp. |

| sumber daya | AC220V 50/60Hz / AC380V 50/60Hz |

| Total konsumsi daya | 12KW |

| Ruang lantai | 4.5mtr x 3.2mtr (meja tetep GF-1530) |

Komponen utama lan Parts

| Jeneng Artikel | Qty | asale |

| Serat laser generator | 1 atur | nLight / IPG |

| Fokus lensa | 1 pc | ⅡⅥ USA |

| Servo motor lan driver | 4 set | YASKAWA (Jepang) |

| Rak lan pinion | 1 atur | YYC |

| Kepala laser fokus dinamis | 1 atur | Raytools (Switherland) |

| Sistem kontrol | 1 atur | Cypcut |

| Panuntun liner | 1 atur | HIWIN |

| Sistem pelumasan otomatis | 1 atur | Laser Emas |

| Chiller banyu | 1 atur | Laser Emas |

| Katup proporsional | 1 atur | SMC (Jepang) |

| Dual (lembar & tabung) Serat Laser Mesin Cutting Model Opsional | ||||

| Model | GF-1540T | GF-1560T | GF-2040T | GF-2060T |

| Area potong | 1,5×4m | 1,5×6m | 2×4m | 2×6m |

| Dawane tabung | 4m | 6m | 4m | 6m |

| sumber laser | IPG/N-light fiber laser resonator | |||

| sumber daya laser | 700W ~ 4KW | |||

EMAS LASER - SERAT LASER nglereni SYSTEMS SERIES

| Model NO. | P2060A | P3080A |

| Panjang Pipa | 6m | 8m |

| Diameter Pipa | 20mm-200mm | 20mm-300mm |

| Daya Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W | |

| Model NO. | P2060 | P3080 |

| Panjang Pipa | 6m | 8m |

| Diameter Pipa | 20mm-200mm | 20mm-300mm |

| Daya Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W | |

| Model NO. | P30120 |

| Panjang Pipa | 12 mm |

| Diameter Pipa | 30mm-300mm |

| Daya Laser | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

| Model NO. | Daya Laser | Area Pemotongan |

| GF-1530 | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W | 1500mm × 3000mm |

| GF-1560 | 1500mm × 6000mm | |

| GF-2040 | 2000mm × 4000mm | |

| GF-2060 | 2000mm × 6000mm | |

| Model NO. | Daya Laser | Area Pemotongan |

| GF-1530T | 700W / 1000W / 1200W / 1500W / 2000W / 2500W / 3000W | 1500mm × 3000mm |

| GF-1560T | 1500mm × 6000mm | |

| GF-2040T | 2000mm × 4000mm | |

| GF-2060T | 2000mm × 6000mm | |

| Model NO. | Daya Laser | Area Pemotongan |

| GF-6060 | 700W / 1000W / 1200W / 1500W | 600mm × 600mm |

Industri aplikasi

Fabrikasi lembaran logam, hardware, kitchenware, elektronik, bagean otomotif, iklan, kerajinan, lampu, dekorasi, perhiasan, kaca tingal, panel elevator, Furnitur, piranti medical, peralatan fitness, eksplorasi lenga, rak tampilan, tetanèn lan mesin kehutanan, mesin pangan, jembatan, kapal, aerospace, bagean struktur, etc.

Materi sing ditrapake

Baja karbon, baja tahan karat, lembaran galvanis, paduan, titanium, aluminium, kuningan, tembaga lan piring lan pipa logam liyane.

Serat Laser Cutting Metal Sheet lan Tube Samples Demonstrasi

Serat Laser Cutting Metal Kekandelan kanggo Powers Laser beda

| Daya Laser | 700W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 8 mm | 10 mm | O2 |

| Baja tahan karat | 3 mm | 4 mm | N2 |

| alumunium | 2 mm | 3 mm | hawa |

| Kuningan | 2 mm | 3 mm | N2 |

| Tembaga | 1 mm | 2 mm | O2 |

| Baja Galvanis | 2 mm | 3 mm | N2 |

| Daya Laser | 1000W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 10 mm | 12 mm | O2 |

| Baja tahan karat | 4 mm | 5 mm | N2 |

| alumunium | 3 mm | 4 mm | hawa |

| Kuningan | 3 mm | 4 mm | N2 |

| Tembaga | 2 mm | 3 mm | O2 |

| Baja Galvanis | 2 mm | 3 mm | N2 |

| Daya Laser | 1200W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 12 mm | 14 mm | O2 |

| Baja tahan karat | 5 mm | 6 mm | N2 |

| alumunium | 3 mm | 4 mm | hawa |

| Kuningan | 3 mm | 4 mm | N2 |

| Tembaga | 2 mm | 3 mm | O2 |

| Baja Galvanis | 3 mm | 4 mm | N2 |

| Daya Laser | 1500W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 12 mm | 14 mm | O2 |

| Baja tahan karat | 5 mm | 6 mm | N2 |

| alumunium | 4 mm | 5 mm | hawa |

| Kuningan | 4 mm | 5 mm | N2 |

| Tembaga | 3 mm | 4 mm | O2 |

| Baja Galvanis | 4 mm | 5 mm | N2 |

| Daya Laser | 2000W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 14 mm | 16 mm | O2 |

| Baja tahan karat | 6 mm | 8 mm | N2 |

| alumunium | 5 mm | 6 mm | hawa |

| Kuningan | 5 mm | 6 mm | N2 |

| Tembaga | 3 mm | 4 mm | O2 |

| Baja Galvanis | 5 mm | 6 mm | N2 |

| Daya Laser | 2500W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 18 mm | 20 mm | O2 |

| Baja tahan karat | 8 mm | 10 mm | N2 |

| alumunium | 6 mm | 8 mm | hawa |

| Kuningan | 6 mm | 8 mm | N2 |

| Tembaga | 4 mm | 6 mm | O2 |

| Baja Galvanis | 5 mm | 6 mm | N2 |

| Daya Laser | 3000W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 20 mm | 22 mm | O2 |

| Baja tahan karat | 10 mm | 12 mm | N2 |

| alumunium | 8 mm | 10 mm | hawa |

| Kuningan | 8 mm | 8 mm | N2 |

| Tembaga | 5 mm | 6 mm | O2 |

| Baja Galvanis | 6 mm | 8 mm | N2 |

| Daya Laser | 4000W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 20 mm | 25 mm | O2 |

| Baja tahan karat | 10 mm | 12 mm | N2 |

| alumunium | 10 mm | 12 mm | hawa |

| Kuningan | 10 mm | 12 mm | N2 |

| Tembaga | 5 mm | 6 mm | O2 |

| Baja Galvanis | 8 mm | 10 mm | N2 |

| Daya Laser | 6000W | ||

| Bahan | Cut resik | Cutting Limit | Gas |

| Baja Ringan | 22 mm | 25 mm | O2 |

| Baja tahan karat | 16 mm | 20 mm | N2 |

| alumunium | 12 mm | 16 mm | hawa |

| Kuningan | 12 mm | 14 mm | N2 |

| Tembaga | 8 mm | 10 mm | O2 |

| Baja Galvanis | 12 mm | 14 mm | N2 |

Hubungi Golden Laser kanggo luwih specification lan petik babaganmesin nglereni serat laser. Tanggepan sampeyan kanggo pitakonan ing ngisor iki bakal mbantu kita nyaranake mesin sing paling cocog.

1.Apa jinis logam sing kudu dipotong? Lembaran logam utawa tabung? Baja karbon utawa stainless steel utawa aluminium utawa baja galvanis utawa kuningan utawa tembaga ...?

2.Yen nglereni sheet metal, apa kekandelan? Apa ukuran kerja sing sampeyan butuhake? Yen nglereni tabung logam utawa pipa, apa kekandelan tembok, diameter lan dawa pipa / tabung?

3.Apa produk rampung sampeyan? Apa industri aplikasi sampeyan?

4.Jeneng, jeneng perusahaan, email, telpon (WhatsApp) lan situs web?