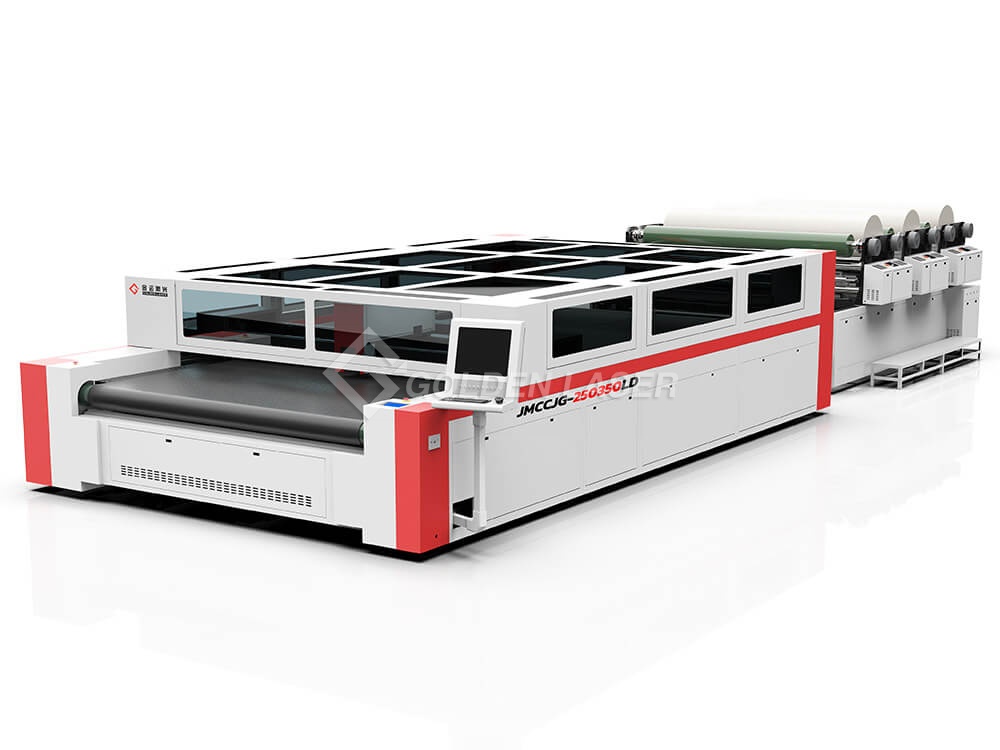

Airbag Laser Cutting Machine with Multi-layer Auto Feeder

Model No.: JMCCJG-250350LD

Introduction:

Goldenlaser solutions dedicated to airbag laser cutting ensure quality, safety and saving, respond to the proliferation and diversification of airbags required by new safety standards. Safety regulations may be changing in the airbag sector, but quality standards are ever more stringent. By combining precision, reliability and speed, Goldenlaser’s specialized airbag laser cutting technologies ensure enhanced productivity and flexibility while maintaining excellent cutting quality.

Laser Cutting System for Airbag Production

→ GOLDENLASER JMC SERIES → High Precision, Fast, Highly Automated

TRADITIONAL PROCESSING VS. LASER CUTTING

The Advantages of Airbags Cutting with Laser

Saving labor

Multi-layer cutting, cutting 10-20 layers at a time, saving 80% of labor compared to single-layer cutting

Shorten the process

Digital operation, design and process integration, no need for tool construction or changeover. After laser cutting, the cut pieces can be directly used for sewing without any post-processing.

High quality, high yield

Laser cutting is thermal cutting, resulting in automatic sealing of the cutting edges. Moreover, laser cutting is high precision and it is not limited by graphics, the yield is as high as 99.8%.

High efficiency, high productivity

Integrating the world's advanced technology and standardized production, the laser cutting machine is safe, stable and reliable. The daily output of a machine is 1200 sets. (Calculated by processing 8 hours per day)

Safe, environmentally friendly and low operating costs

The core components are maintenance-free, require no additional consumables, and cost only about 6 kWh per hour.

The laser cutting machine uses a 600 watt CO2 RF laser as the laser source. Now cut 20 layers of airbag material at a time.

The display screen of the laser cutting machine on-site indicates that 3 sets of single layout in the format, using 2580mm width fabric, cutting time about 12 minutes.

ACCORDING TO THE DATA

A laser cutting machine can cut 60 sets of airbags every 12 minutes (20 layers × 3 sets)

About 300 sets per hour (60 sets × (60/12))

Based on 8 hours working time per day, about 2400 sets can be cut per day.

Only one manual operation is required.

Consumables only need 6kwh per hour.

Four Reason to Choose GOLDENLASER JMC SERIES Laser Cutting System

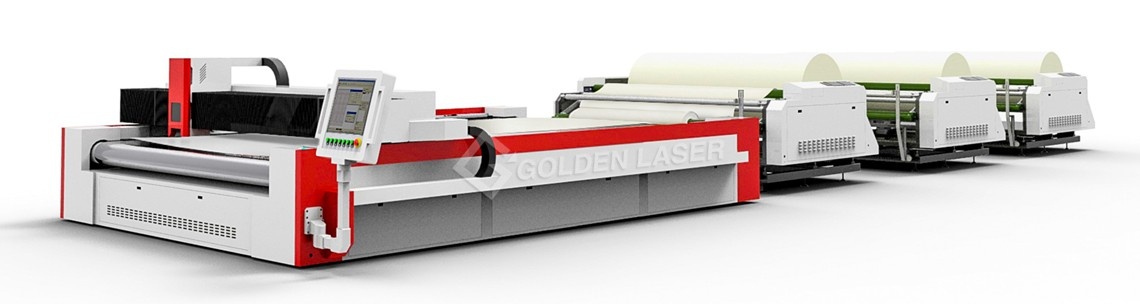

1. Precision tension feeding

No tension feeder will easy to distort the variant in the feeding process, resulting the ordinary correction function multiplier; Tension feeder in a comprehensive fixed on both sides of the material at the same time, with automatically pull the cloth delivery by roller, all process with tension, it will be perfect correction and feeding precision.

2. High-speed cutting

Rack and pinion motion system equipped with high-power laser, reach to 1200 mm/s cutting speed, 8000 mm/s2 acceleration speed.

3. Automatic sorting system

Fully automatic sorting system. Make the material feeding, cutting, sorting at one time.

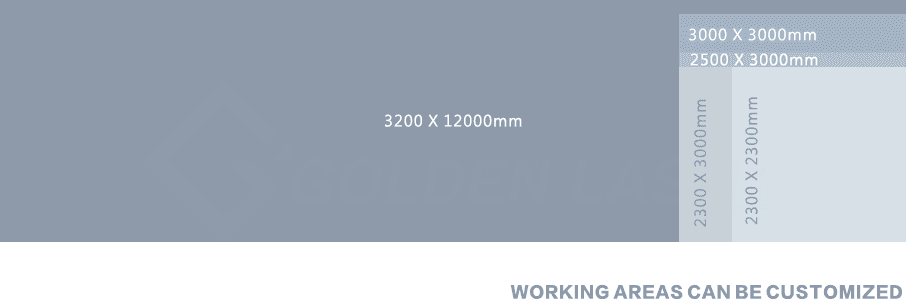

4. Customizing the size of the high-precision laser cutting bed

2300mm×2300mm (90.5 inch×90.5 inch), 2500mm×3000mm(98.4 inch×118 inch), 3000mm×3000mm (118 inch×118 inch), Or optional.

Watch Laser Cutting Machine for Airbag in Action!

Technical Parameters of the Cutting Laser Machine

| Laser source | CO2 RF laser |

| Laser power | 150 watt / 300 watt / 600 watt / 800 watt |

| Working area (W×L) | 2500mm×3500mm (98.4” ×137.8”) |

| Working table | Vacuum conveyor working table |

| Cutting speed | 0-1200mm/s |

| Acceleration | 8000mm/s2 |

| Repeated positioning accuracy | ≤0.05mm |

| Moving system | Offline mode servo motor motion system, High precision gear rack driving |

| Power supply | AC220V±5% / 50Hz |

| Format support | AI, BMP, PLT, DXF, DST |

| Options | Auto feeder, red dot positioning, marker pen, Galvo system, double head |

JMC SERIES LASER CUTTING MACHINE RECOMMENDED MODELS

→ JMCCJG-230230LD. Working Area 2300mmX2300mm (90.5 inch×90.5 inch) Laser Power: 150W / 300W / 600W / 800W CO2 RF Laser

→ JMCCJG-250300LD. Working Area 2500mm×3000mm (98.4 inch×118 inch) Laser Power: 150W / 300W / 600W / 800W CO2 RF Laser

→ JMCCJG-300300LD. Working Area 3000mmX3000mm (118 inch×118 inch) Laser Power: 150W / 300W / 600W / 800W CO2 RF Laser

… …

Please contact GOLDEN LASER for more information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp…)?