Roll to Roll Laser Cutting Machine

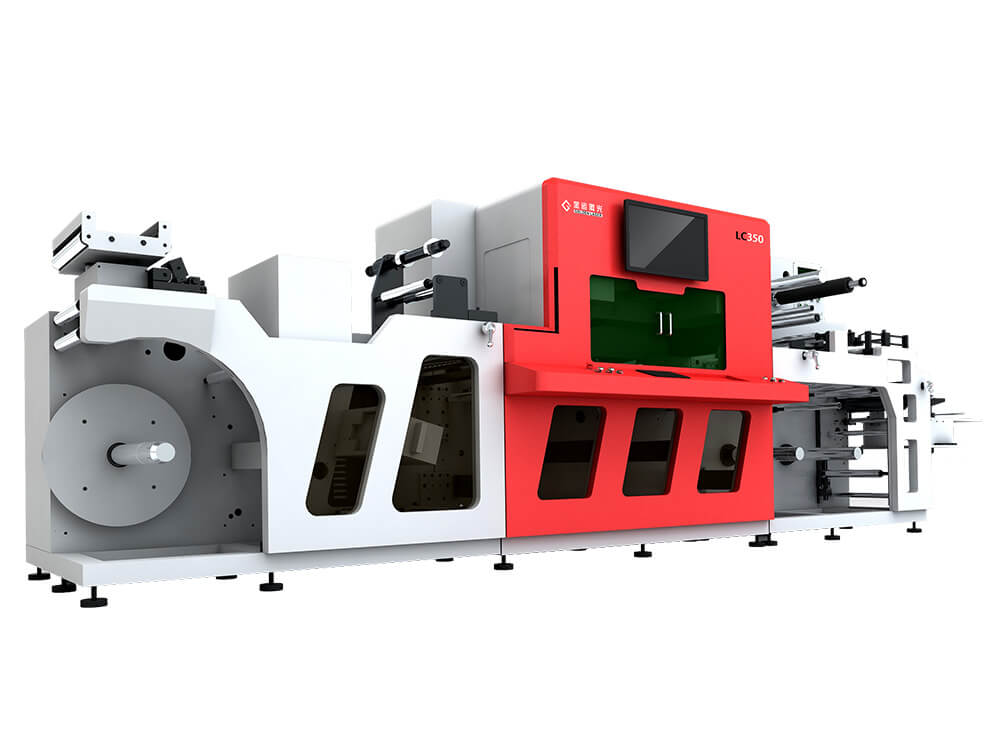

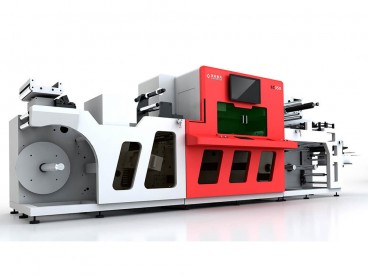

Inombolo yemodeli: LC-350

Isingeniso:

- Ukukhiqizwa okudingekayo, impendulo esheshayo kuma-oda wesikhathi esifushane.

- Akukho ukulinda ukufa okusha. Asikho isitoreji samathuluzi e-die.

- Ukuskena kwekhodi yebha / ikhodi ye-QR kusekela ukushintsha okuzenzakalelayo lapho undiza.

- Idizayini ye-modular ifanela izidingo zokukhiqiza ngazinye zamakhasimende.

- Ukufakwa kalula. Usekelo lwesiqondiso sokufaka ukude.

- Ukutshalwa kwezimali kwesikhathi esisodwa, izindleko zokunakekela eziphansi.

- Uhlobo lwe-Laser:I-CO2 RF laser

- Amandla e-Laser:150W / 300W / 600W

- Ubukhulu. ukusika ububanzi:350mm (13.7")

- Ubukhulu. ububanzi be-roll :370mm (14.5")

Umshini Wokusika I-Laser Wokuguqula Ilebula

II-Laser Cutting & Converting Systeminikeza izixazululo ezintsha nezingabizi kakhulu zokucubungula amajiyometri alula futhi ayinkimbinkimbi ukuze kuqedwe ilebula ngaphandle kokusebenzisa amathuluzi okudayi endabuko - ingxenye yekhwalithi ephezulu engakwazi ukuphindaphindwa enqubweni yokusika ukufa okujwayelekile. Lobu buchwepheshe bukhulisa ukuguquguquka kokuklama, bubiza kahle ngomthamo wokukhiqiza wekhwalithi ephezulu, bunciphisa udoti wezinto ezibonakalayo ngokulungiswa okuphansi kakhulu.

I-Laser Technology iyisixazululo esifanelekile sokusika nokuguqula esisebenza ngesikhathi kanye nokugijima okufushane futhi ifaneleka kahle ukuguqula izingxenye ezinemba okuphezulu kusuka ezintweni eziguquguqukayo ezihlanganisa amalebula, izinto zokunamathisela ezinhlangothini ezimbili, ama-gaskets, amapulasitiki, izindwangu, izinto ezi-abrasive, njll.

I-LC350 Laser Die Cutting Machineenomklamo wekhanda wokuskena wemithombo emibili ihlangabezana namalebula amaningi nezinhlelo zokusebenza zokuphrinta zedijithali.

Ezinye zezinhlelo zokusebenza ezijwayelekile zifaka:

Imininingwane

Ipharamitha Eyinhloko Yezobuchwepheshe Yomshini Wokusika I-Laser Die we-LC350 Wokuqeda Ilebula

| Uhlobo lwe-laser | I-CO2 RF yensimbi laser |

| Amandla e-laser | 150W / 300W / 600W |

| Ubukhulu. ukusika ububanzi | 350mm / 13.7” |

| Ubukhulu. ukusika ubude | Okungenamkhawulo |

| Ubukhulu. ububanzi bokudla | 370mm / 14.5” |

| Ubukhulu. ububanzi bewebhu | 750mm / 29.5” |

| Ubukhulu. isivinini sewebhu | 120m/min (Isivinini siyahlukahluka kuye ngezinto ezibonakalayo kanye nephethini yokusika) |

| Ukunemba | ±0.1mm |

| Ukunikezwa kwamandla kagesi | 380V 50/60Hz 3 izigaba |

Izici Zomshini

I-LC350 Laser Die Cutting Machine Ukucushwa Okujwayelekile:

Ukuqaqa + Umhlahlandlela Wewebhu + Ukusika i-Laser + Ukususwa Kwemfucuza + Ukubuyisela emuva kabili

I-QR Code Readerivumela ukushintsha okuzenzakalelayo. Ngale nketho, umshini uyakwazi ukucubungula imisebenzi eminingi ngesinyathelo esisodwa, shintsha ukumiswa kokusika (ukusika iphrofayili kanye nesivinini) lapho undiza.

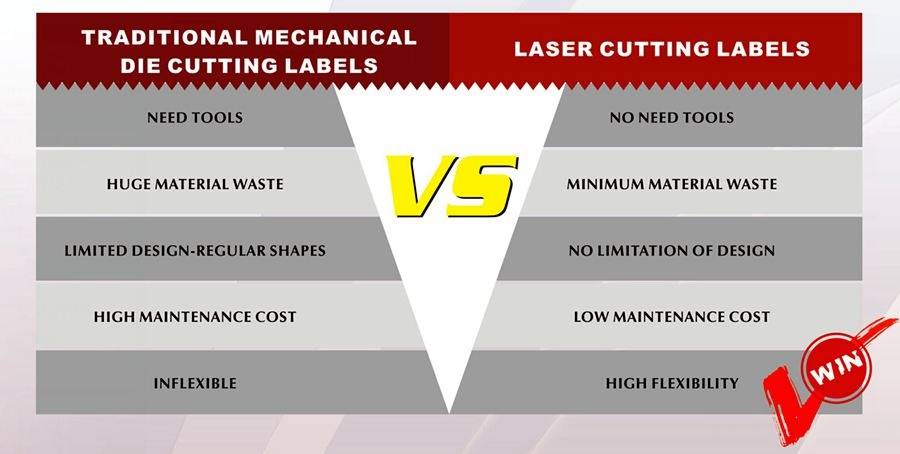

Yiziphi izinzuzo zokusika amalebula we-laser?

Ukushintsha ngokushesha

Yonga isikhathi, izindleko nezinto zokwakha

Akukho umkhawulo wamaphethini

Ukuzenzakalela kwayo yonke inqubo

Uhlu olubanzi lwezinto zokusetshenziswa

Idizayini ye-modular yemisebenzi eminingi

Ukunemba kokusika kufika ku-±0.1mm

Amalaser amabili anwebekayo anesivinini sokusika esingafika ku-120 m/min

Ukusika ukuqabula, ukusika ngokugcwele, ukubhoboza, ukuqopha, ukumaka...

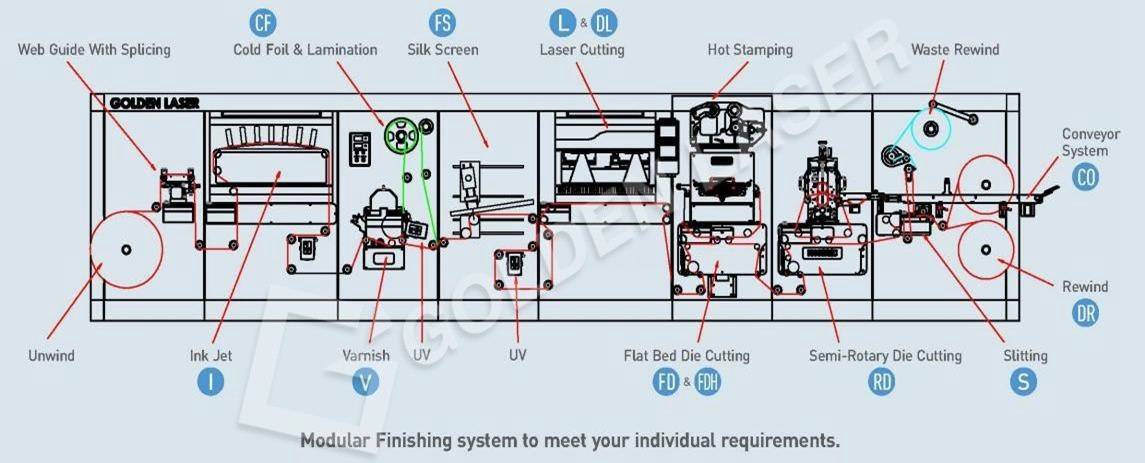

IZINHLELO ZOKUQEDA

Amasistimu wokuqeda ama-modular atholakalayo ukuze ahlangabezane nezidingo zakho ngazinye.

Umshini wokusika we-laser unokuguquguquka kokwenziwa ngezifiso ngezinketho ezahlukene zokuguqula ukuze uthuthukise imikhiqizo yakho futhi unikeze ukusebenza kahle emgqeni wakho wokukhiqiza.

Umhlahlandlela Wewebhu

Iyunithi ye-Flexo

I-Lamination

Inzwa Yokubhalisa Umaka Nesishumeki

I-Blades Slitting

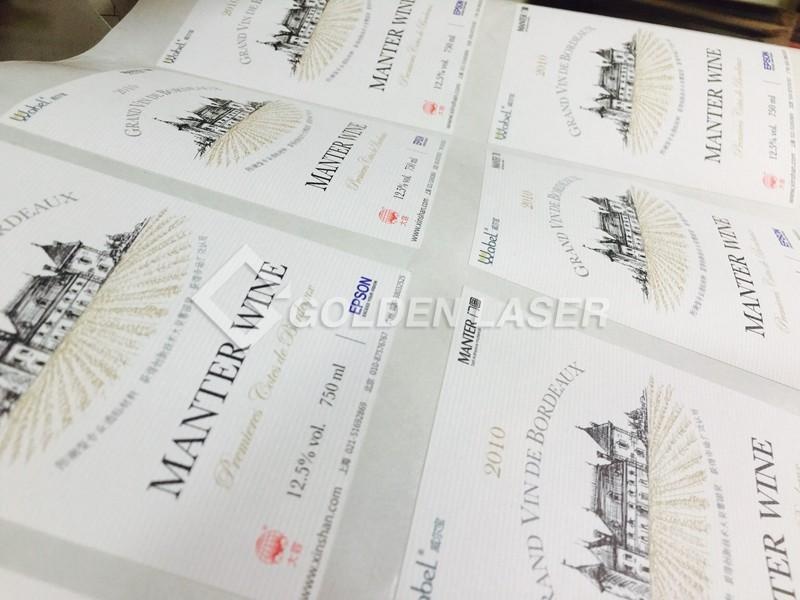

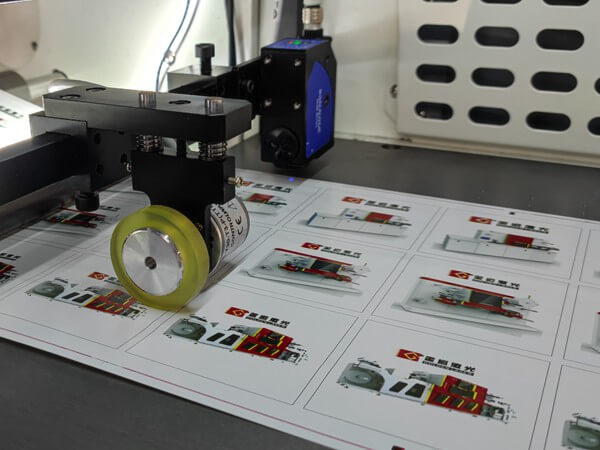

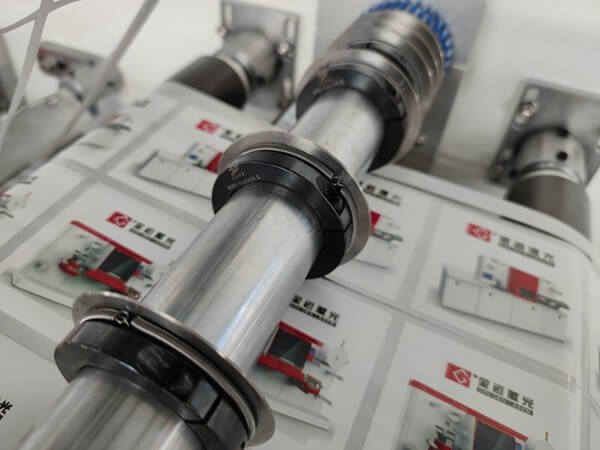

AMANYE AMASAMPELA

Imisebenzi Emangalisayo Enikelwe Umshini Wokusika I-Laser Die.

Imingcele Yezobuchwepheshe yeI-LC350 Laser Die Cutting Machine

| Imodeli No. | I-LC350 |

| Uhlobo lwe-laser | I-CO2 RF yensimbi laser |

| Amandla e-laser | 150W / 300W / 600W |

| Ubukhulu. ukusika ububanzi | 350mm / 13.7” |

| Ubukhulu. ukusika ubude | Okungenamkhawulo |

| Ubukhulu. ububanzi bokudla | 370mm / 14.5” |

| Ubukhulu. ububanzi bewebhu | 750mm / 29.5” |

| Isivinini sewebhu | 0-120m/min (Isivinini siyahlukahluka kuye ngezinto ezibonakalayo nephethini yokusika) |

| Ukunemba | ±0.1mm |

| Ubukhulu | L 3700 x W 2000 x H 1820 (mm) |

| Isisindo | 3000Kg |

| Ukunikezwa kwamandla kagesi | 380V 3 izigaba 50/60Hz |

| Amandla okupholisa amanzi | 1.2KW-3KW |

| Amandla wesistimu yokukhipha | 1.2KW-3KW |

*** Qaphela: Njengoba imikhiqizo ivuselelwa njalo, sicela usithinte ukuze uthole imininingwane yakamuva. ***

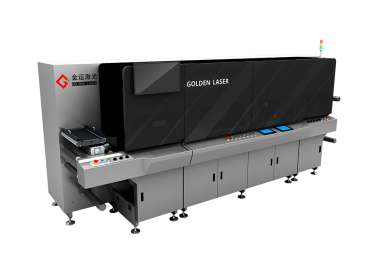

Amamodeli Ajwayelekile we-Goldenlaser Wemishini Yokusika I-Laser Die Die

| Imodeli No. | I-LC350 | I-LC230 |

| Ubukhulu. ukusika ububanzi | 350mm / 13.7″ | 230mm / 9″ |

| Ubukhulu. ukusika ubude | Okungenamkhawulo | |

| Ubukhulu. ububanzi bokudla | 370mm / 14.5” | 240mm / 9.4” |

| Ubukhulu. ububanzi bewebhu | 750mm / 29.5″ | 400mm / 15.7″ |

| Ubukhulu. isivinini sewebhu | 120m/min | 60m/min |

| Isivinini siyahlukahluka kuye ngokuthi impahla kanye nephethini yokusika | ||

| Uhlobo lwe-laser | I-CO2 RF yensimbi laser | |

| Amandla e-laser | 150W / 300W / 600W | 100W / 150W / 300W |

| Umsebenzi ojwayelekile | Ukusika okugcwele, ukusika ukuqabula (ukusika isigamu), ukubhoboza, ukuqopha, ukumaka, njll. | |

| Umsebenzi ozikhethela wona | Lamination, UV varnish, slitting, njll. | |

| Izinto zokucubungula | Ifilimu yepulasitiki, iphepha, iphepha elicwebezelayo, i-matt paper, i-polyester, i-polypropylene, i-BOPP, ipulasitiki, ifilimu, i-polyimide, amateyipu akhanyayo, njll. | |

| Ifomethi yosekelo lwesoftware | I-AI, BMP, PLT, DXF, DST | |

| Ukunikezwa kwamandla kagesi | 380V 50HZ / 60HZ Izigaba ezintathu | |

Uhlelo Lokuguqula I-Laser

Izinto ezijwayelekile ezisetshenziselwa imishini yokusika i-laser zifaka:

Iphepha, ifilimu yepulasitiki, iphepha elicwebezelayo, iphepha le-matt, iphepha lokwenziwa, amakhadibhodi, i-polyester, i-polypropylene (PP), i-PU, i-PET, i-BOPP, ipulasitiki, ifilimu, ifilimu ye-microfinishing, njll.

Izicelo ezijwayelekile zemishini yokusika i-laser zifaka:

- Amalebula

- Amalebula Okunamathelayo kanye Amatheyipu

- Amateyipu akhombisayo / amafilimu e-Retro Reflective

- Amatheyipu emboni

- Izitika / Izitika

- Ama-Abrasives

- Ama-Gaskets

I-Laser UNIQUE Izinzuzo zokusika amalebula e-Roll to Roll

| - Ukuzinza kanye Nokwethenjelwa |

| Umthombo we-laser we-Co2 RF ovaliwe, ikhwalithi yokusikwa ihlala iphelele futhi ihlala njalo ngokuhamba kwesikhathi ngezindleko eziphansi zokulungiswa. |

| - Ijubane eliphezulu |

| Uhlelo lwe-Galvanometric luvumela ubhontshisi ukuthi uhambe ngokushesha okukhulu, ugxile ngokuphelele kuyo yonke indawo yokusebenza. |

| - Ukunemba okuphezulu |

| Uhlelo olusha Lokumisa Ilebula lulawula indawo yewebhu ku-eksisi X kanye ne-Y. Le divayisi iqinisekisa ukunemba kokusika phakathi kwama-micron angama-20 ngisho nokusika amalebula anegebe elingajwayelekile. |

| - Iguquguquke ngokwedlulele |

| Umshini waziswa kakhulu ngabakhiqizi bamalebula njengoba ungakha izinhlobonhlobo ezinkulu zamalebula, ngenqubo eyodwa yejubane eliphezulu. |

| - Ifanele ukusebenza anhlobonhlobo impahla |

| Iphepha elicwebezelayo, iphepha le-matt, amakhadibhodi, i-polyester, i-polypropylene, i-polyimide, i-polymeric film synthetic, njll. |

| - Ifanele izinhlobo ezahlukene zomsebenzi |

| Ukufa ukusika noma yiluphi uhlobo lomumo - ukusika nokuqabula ukusika - ukubhoboza - ukubhoboza okuncane - ukuqoshwa |

| - Akukho umkhawulo wokuklama kokusika |

| Ungakwazi ukusika umklamo ohlukile ngomshini we-laser, kungakhathaliseki ukuthi umumo noma usayizi |

| -Minimal Material Waste |

| Ukusika i-laser kuyinqubo yokushisa engathinteki. I-tt ine-slim laser beam. Ngeke kubangele noma iyiphi imfucuza mayelana nezinto zakho. |

| -Gcina izindleko zakho zokukhiqiza kanye nezindleko zokuyilungisa |

| Ukusika i-laser asikho isidingo sesikhunta/ummese, asikho isidingo sokwenza isikhunta sokuklama okuhlukile. Ukusika kwe-Laser kuzokongela izindleko eziningi zokukhiqiza; futhi umshini we-laser unesikhathi eside usebenzisa impilo, ngaphandle kwezindleko zokushintshwa kwesikhunta. |

<<Funda kabanzi mayelana ne-Roll to Roll Label Laser Cutting Solution