Vision Laser Cutting Machine for Sublimation Printed Fabrics

Model No.: CJGV-190130LD

Introduction:

Laser cutting integrated with vision recognition system serves as a perfect laser cutting machine for dye sublimation printed fabrics finishing. Cameras scan the fabric during the conveyor advancing, detect and recognize printed patterns contour or pick up printed registration marks, and send the cutting information to the laser cutting machine. This process is repeating after the machine finishes to cut the current format. The entire process is completely automated.

The Vision System is a software / hardware solution designed to detect / adjust the shape and position of the patterns according to the fabrics based on optical recognition. The Vision System is integrated with a laser cutting machine and offers a flexible solution for a wide range of applications.

Whether you are in the industry of sportswear, fast fashion, merchandising clothes, interior decoration or soft signage, as long as you have the demand of dye sublimation printed fabrics finishing, the Vision Laser serves as a perfect laser cutting system.

Specifications

| Working area | 1900mm×1300mm / 74.8"×51" |

| Camera scanning area | 1880mm×1300mm / 74"×51" |

| Laser type | CO2 glass laser / CO2 RF metal laser |

| Laser power | 70W / 100W / 150W |

| Working table | Conveyor working table |

| Control system | Servo motor control system |

| Software | Goldenlaser CAD Scanning Software Package |

| Other options | Auto feeder, red dot pointer |

How Vision System Works?

› Cameras scan the fabric during the conveyor advancing, detect and recognize printed patterns contour or pick up printed registration marks, and send the cutting information to the laser cutting machine. This process is repeating after the machine finishes to cut the current cutting window. The entire process is completely automated.

› The Vision System can be adapted on laser cutters of any dimensions; the only factor which depends on cutter width is the number of cameras.

› Depending of required cutting precision the number of cameras will be increased / decreased. For most of the practical applications, 90cm of cutter width requires 1 camera.

On-the-fly Scanning with Vision recognition

Enhance your level of productivity with the Vision system. This laser advanced technology instantly scans the printed material without operator intervention, without the need for cut files.

High-production processing of printed textiles can rely on the Vision Laser Cutting Machine. Enjoy the benefits of an automated workflow, reduced idle periods and maximum use of material with a minimum of waste.

State-of-the-art camera recognition is used to quickly scan the material and to automatically create the vectors for cutting. Alternatively, the marks can be accurately read by the camera, allowing our intelligent analysis to compensate for any deformations. When the laser cut pieces exit the machine, they are perfectly cut, according to the design. Each time again.

The Vision technology is able to quickly scan the material on the cutting bed, automatically create a cut vector and cut the whole roll without operator intervention. There will be no need to create cut files/designs. With only a click of a button, any design file loaded into the machine will be cut with quality sealed edges.

The vision laser cutting machine is equipped with the best quality CO2 laser source and will excel in a high volume production environment.

The vacuum conveyor will accurately feed and cut any length shape or nested design with unrivalled speed.

Watch Vision Laser Cutting in Action

Vision Scan On-the-fly Laser Cutting for Dye-sublimation Printed Sportswear and Masks

Technical Parameters of the Vision Laser Cutter

| Working area | 1900mm×1300mm / 74.8″×51″ |

| Camera scanning area | 1880mm×800mm / 74″×31.4″ |

| Working table | Conveyor working table |

| Laser power | 70W / 100W / 150W |

| Laser tube | CO2 glass laser tube / CO2 RF metal laser tube |

| Control system | Servo motor control system |

| Cooling system | Constant temperature water chiller |

| Exhaust system | 1.1KW exhaust fan × 2, 550W exhaust fan × 1 |

| Power supply | 220V 50Hz / 60Hz, single phase |

| Electrical standard | CE / FDA / CSA |

| Power consumption | 9KW |

| Software | Goldenlaser CAD Scanning Software Package |

| Other options | Auto feeder, red dot point |

GOLDENLASER Full Range of Vision Camera Laser Cutting Systems

Ⅰ High Speed Scan On-the-Fly Cutting Series

| Model No. | Working area |

| CJGV-160130LD | 1600mm×1300mm (63”×51”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

Ⅱ High Precision Cutting by Registration Marks

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

Ⅲ Ultra-Large Format Laser Cutting Series

| Model No. | Working area |

| ZDJMCJG-320400LD | 3200mm×4000mm (126”×157.4”) |

Ⅳ Smart Vision (Dual Head) Laser Cutting Series

| Model No. | Working area |

| QZDMJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

Ⅴ CCD Camera Laser Cutting Series

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

Applicable Industries of the Vision Laser Cutting Machine

Sportswear

Sports jerseys, cycling apparel, legging and related sports gear

Fashion apparel and accessories

T-shirts, polo shirts, dresses, swimwear, hand bags, masks

Home decoration

Tablecloths, pillows, curtains, wall decorations, and furnishings.

Flags, banners and soft signage

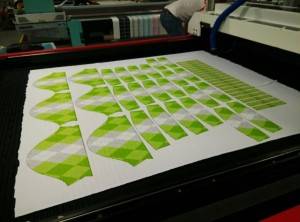

Vision Laser Cutting Dye Sublimation Fabrics Samples

<< See More Samples about Vision Laser Cutting Sublimation Prints

Availability of Vision System

1. On the fly – large format recognition continuous cutting

This function is for patterned fabric precisely positioning and cutting. For example, through digital printing, various graphics printed on fabric. In the subsequent of positioning and cutting, material information extracted by the high-speed industrial camera (CCD), software smart identification closed outer contour graphics, then automatically generates the cutting path and finish cutting. Without the need for human intervention, it can achieve continuous recognition cutting of the entire roll printed fabrics. I.e. by large format visual recognition system, the software automatically recognize the contour pattern of the garment, and then automatic contour cutting graphics, thus ensuring accurate cutting of the fabric.

Advantage of contour detection

- No required the original graphics files

- Directly detect roll printed fabrics

- Automatic without manual intervention

- Identification within 5 seconds on the whole cutting area

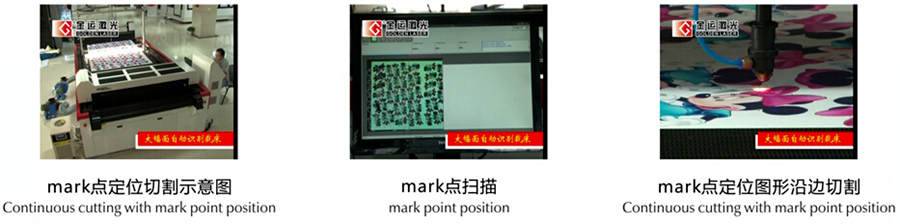

2. Printed Marks Cutting

This cutting technology is applicable to a variety of patterns and labels precision cutting. Especially suitable for automatic continuous printing clothing contour cutting. Marker point positioning cutting no pattern size or shape restrictions. Its positioning is only associated with two Marker points. After two Marker points to identify the location, entire format graphics can be precisely cut. (Note: arrangement rules must be the same for each format of the graphic. Automatic feeding continuous cutting, to be equipped with feeding system.)

Advantage of printed marks detection

- High precision

- Unlimited for the distance between printed pattern

- Unlimited for printing design and background color

- Compensation of processing material deformation

3. Strips and Plaids Cutting

CCD camera, which is installed in the rear of the cutting bed, can recognize materials information such as stripes or plaids according to color contrast. The nesting system can perform automatic nesting according to the identified graphical information and cut pieces requirement. And can automatically adjust the pieces angle to avoid stripes or plaids distortion on the feeding process. After nesting, the projector would emit red light to mark the cutting lines on materials for calibration.