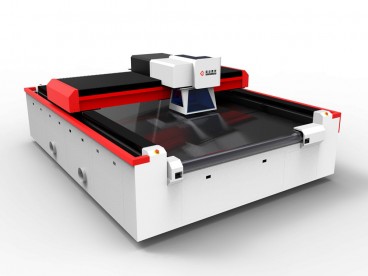

Mashiinka Goynta Dharka Laser-ka ee Shaandhaynta oo leh Nidaamyo otomaatig ah

Tusaalaha No.: JMCJG-300300LD

Hordhac:

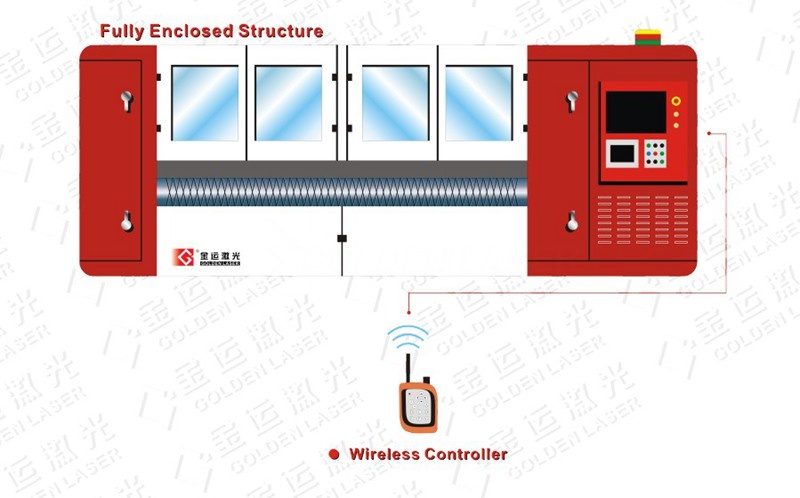

- Qaab dhismeedka si buuxda u xidhan.

- Gear iyo rack la wado - xawaare sare iyo saxsanaan sare.

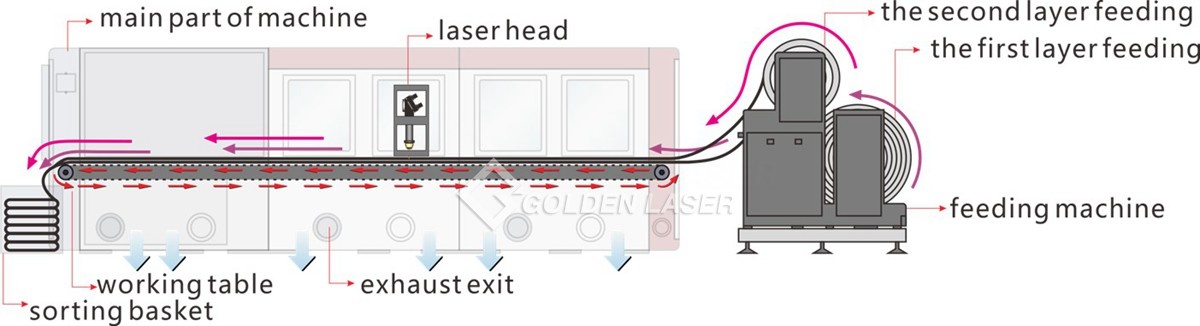

- Habab otomaatig ah oo wata gaadiid-qaade iyo feedhiyaha otomaatiga ah.

- Qaab weyn oo goobta shaqada - Cabbirrada miiska la beddeli karo.

- Ikhtiyaarada: moduleka calaamadaynta iyo nidaamka kala soocida tooska ah.

- isha Laser:CO2 laser

- Awoodda leysarka:150watt, 300watt, 600watt, 800watt

- Goobta shaqada:3000mm×3000mm (118"×118")

- Codsiga:Shaandheeyaha marada saxaafadeed, sariiraha shaandhaynta, agabka shaandhaynta iyo teksiyada farsamada

GOLDENLASER JMC TAXANAHA CO2 Laser Goynta Machine

Laser socodka habayn toos ah

Wax-soo-saarkayaga heerka sare ah ee mashiinka goynta laser CO2, balaadhinta hawlaha badan, qaabeynta quudinta tooska ah iyo nidaamyada kala-soocidda, cilmi-baarista iyo horumarinta software-ka wax-ku-oolka ah ... Dhammaan si loo siiyo macaamiisha waxtarka wax-soo-saarka sare, habka wax-soo-saarka la hagaajiyay, badbaadinta kharashka dhaqaalaha iyo kharashka waqtiga, iyo kor u qaadista faa'iidooyinka.

Heerarka Mashiinka Goynta Taxanaha JMC

1. Qaab dhismeedka si buuxda u xidhan

Laydhka qaabka weyn ee goynta sariirta oo leh qaab-dhismeed si buuxda u xiran si loo hubiyo in boodhka goynta uusan daadin, oo ku habboon hawlgalka warshadda wax soo saarka ee xooggan.

Intaa waxaa dheer, gacan-ku-haynta wireless-ka ee user-saaxiibtinimo waxay xaqiijin kartaa hawlgalka fog.

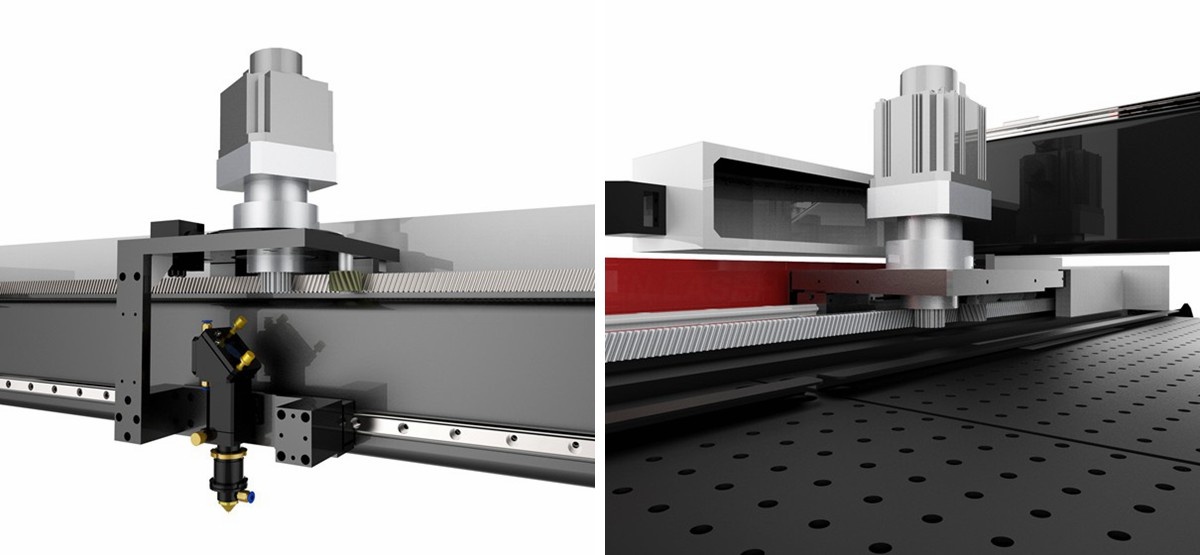

2. Gear & Rack wadey

Saxnimo sareGear & Rack wadistanidaamka. Goynta xawaaraha sare. Xawaaraha ilaa 1200mm/s, dardargelinta 10000mm/s2, waxayna ilaalin kartaa xasilloonida muddada dheer.

- Heer sare oo sax ah iyo ku celin.

- Hubi tayada goynta aad u fiican.

- Waarta oo awood badan. Wax soo saarkaaga 24/7 saac.

- Nolosha adeegga in ka badan 10 sano.

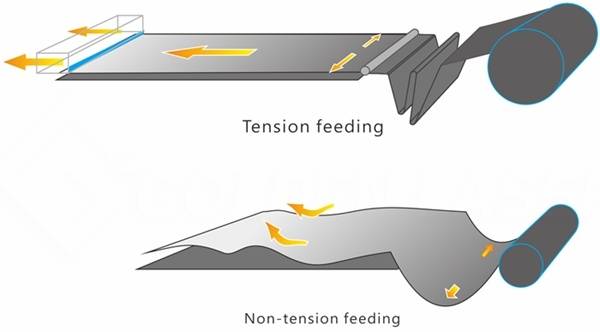

3. Quudinta xiisadda saxda ah

Tilmaamaha quudiyaha tooska ah:

- ballaca hal rullaluistu wuxuu u dhexeeyaa 1.6 mitir ~ 8 mitir; dhexroorka ugu badan ee duubku waa 1 mitir; Miisaanka la awoodi karo ilaa 500 KG

- Quudinta tooska ah ee soo jiidashada dharka; Sixitaanka leexashada midig-iyo-bidix; Meelaynta walxaha iyadoo la xakameynayo cidhifka

Quudinta xiisadda saxda ah

Ma jiro feedhyahan kacsanaan ah oo si fudud u qalloocin doona kala duwanaanshaha habka quudinta, taas oo keenta in ay badiyaan shaqada saxda ah ee saxda ah;

Quudinta kacsanaantasi dhammaystiran u go'an labada dhinac ee walxaha isku mar, iyadoo si toos ah u jiid bixinta maro by rullaluistemadka, dhammaan habka xiisadda, waxa ay noqon doontaa saxan qumman iyo quudinta saxda ah.

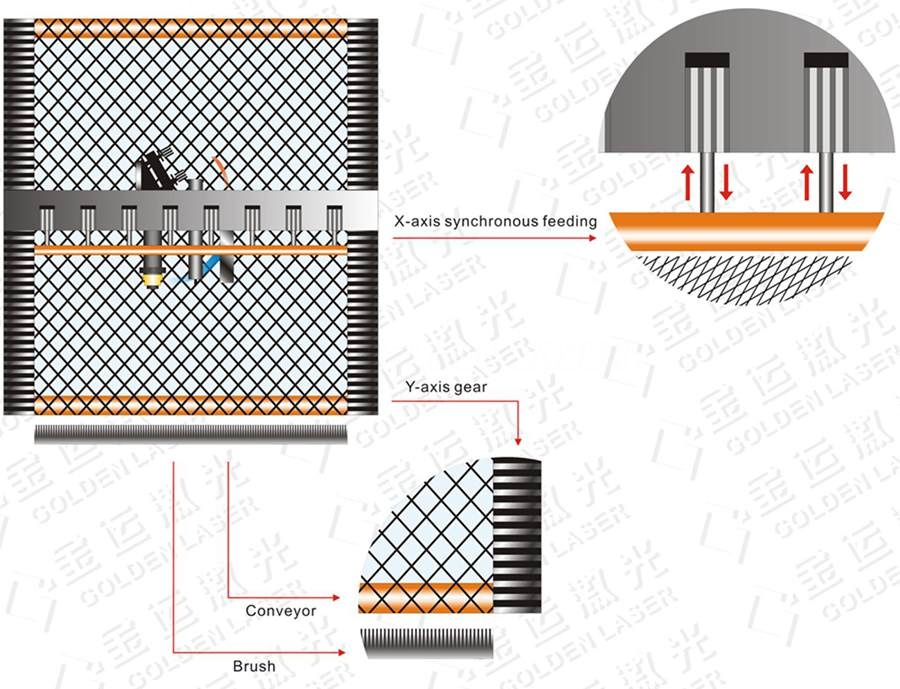

X- dhidibka quudinta isku mid ah

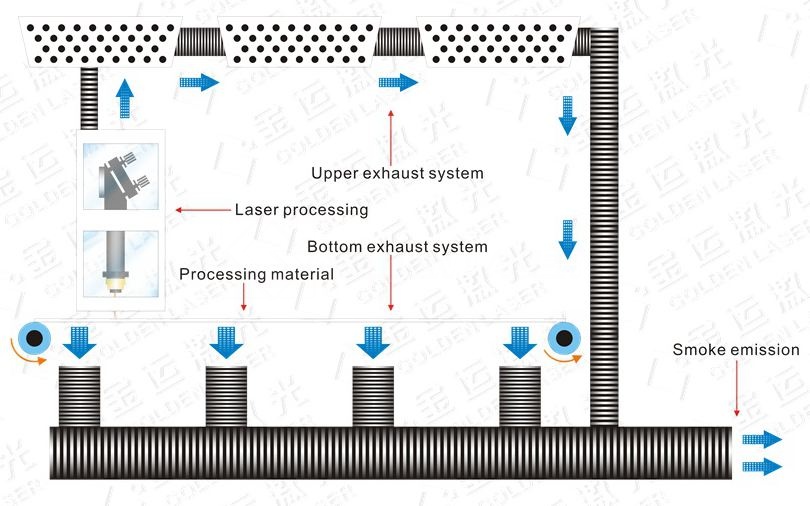

4. Unugyada daminta iyo shaandhaynta

Faa'iidooyinka

Had iyo jeer gaadho tayada goynta ugu badan

• Qalab kala duwan ayaa lagu dabaqaa miisaska shaqada ee kala duwan

• Si madax banaan u xakameynta soo saarista kor ama hoos

• Cadaadiska nuugista miiska oo dhan

• Hubi tayada hawada ugu fiican ee deegaanka wax soo saarka

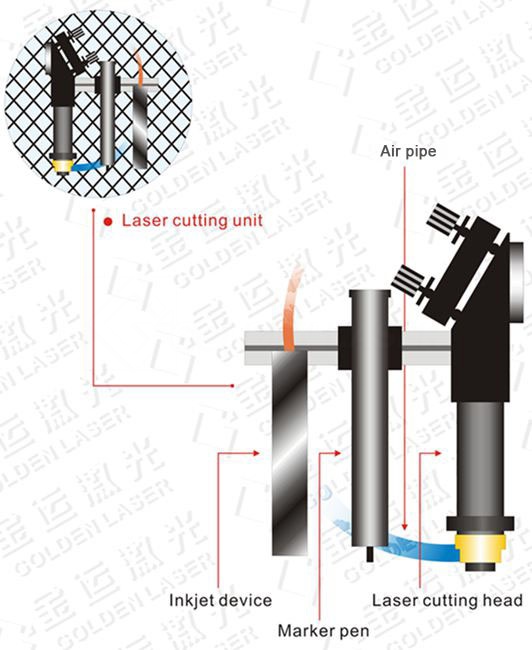

5. Nidaamyada calaamadaynta

Marka loo eego shuruudaha macaamiisha, qalabka daabacaadda khad-jet-ka ee aan xiriir la lahayn iyo qalabka qalinka calaamadda ayaa lagu rakibi karaa madaxa laser si loo calaamadiyo walxaha shaandhada, taas oo ku habboon tolida dambe.

Hawlaha daabacaha khad-jet:

1. Calaamadee jaantusyada oo si sax ah u jar geesta

2. Number off-cut

Hawl-wadeenadu waxay ku calaamadin karaan meel-ka-baxsan iyagoo wata macluumaadka qaar sida cabbirka go'ay iyo magaca hadafka

3. Calaamadayn aan xidhiidh la lahayn

Calaamadayn la'aanta ayaa ah doorashada ugu fiican ee tolida. Khadadka goobta saxda ah waxay ka dhigaan shaqada xigta si fudud.

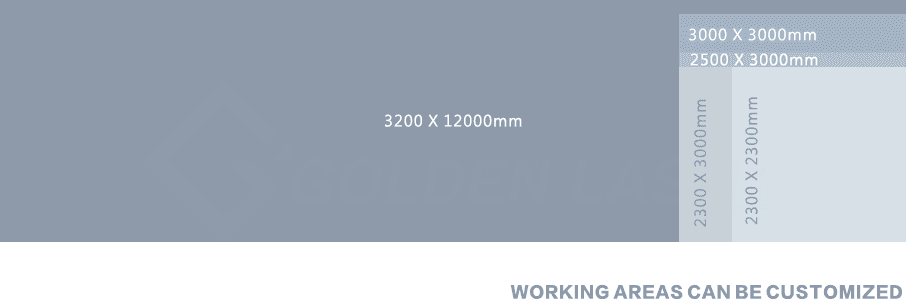

6. Meelaha goynta la beddeli karo

2300mm × 2300mm (90.5in × 90.5in), 2500mm × 3000mm (98.4in × 118in), 3000mm × 3000mm (118in × 118in), 3500mm × 4000mm (137.7in×157.4in) ama fursadaha kale Meesha ugu weyn ee shaqada waa ilaa 3200mm × 12000mm (126in×472.4in)

Daawo Mashiinka Goynta Laser-ka ee Maro Saxafadeed Shaandhayso oo shaqaynaysa!

Qiyaasta Farsamada

| Nooca laser | CO2 RF laser tube |

| Awoodda leysarka | 150W / 300W / 600W / 800W |

| Aagga Goynta | 3000mm×3000mm (118"×118") |

| Miiska shaqada | vacuum conveyor miiska shaqada |

| Habka dhaqdhaqaaqa | Gear iyo rack lagu wado, Servo motor |

| Xawaaraha jarista | 0-1200mm/s |

| Dardargelinta | 8000mm/s2 |

| Nidaamka saliidda | Nidaamka sifaynta tooska ah |

| Nidaamka soo saarista qiiqa | Tuubooyin khaas ah oo isku xidha oo leh N centrifugal afuufayaasha |

| Nidaamka qaboojinta | Habka qaboojiyaha asalka ah ee biyaha |

| Madaxa laser | Processional CO2 madaxa goynta laser |

| Xakamaynta | Nidaamka xakamaynta khadka tooska ah |

| Ku soo celi saxnaanta meelaynta | ±0.03mm |

| Meelaynta saxnaanta | ±0.05mm |

| Min. kerf | 0.5 ~ 0.05mm (waxay kuxirantahay walxaha) |

| Awoodda guud | ≤25KW |

| Qaab la taageeray | PLT, DXF, AI, DST, BMP |

| Korontada | AC380V± 5% 50/60Hz 3 Waji |

| Shahaado | ROHS, CE, FDA |

| Ikhtiyaarada | Quudiye toos ah, meelaynta dhibicda cas, Nidaamka calaamadaynta, nidaamka Galvo, madax labanlaab ah, kamarad CCD |

※ Goobaha shaqada waa la habeyn karaa haddii la codsado.

Qaybaha ugu muhiimsan iyo qaybaha

| Magaca Maqaalka | Qty | Asal ahaan |

| Tuubada laser | 1 set | Rofin (Jarmalka) / Isku-xidhan (USA) / Synrad (USA) |

| Muraayada diirada | 1 pc | II IV USA |

| Servo motor iyo darawalka | 4 qaybood | YASKAWA (Japan) |

| Rack iyo pinion | 1 set | Atlanta |

| Madaxa leysarka diirada firfircoon | 1 set | Raytools |

| Gear yareeya | 3 qaybood | Alfa |

| Nidaamka xakamaynta | 1 set | GoldenLaser |

| Hagaha laynka | 1 set | Rexroth |

| Habka saliidaynta tooska ah | 1 set | GoldenLaser |

| Biyo qaboojiye | 1 set | GoldenLaser |

JMC TAXANAHA LAASERKA MAASHINKA GOOYNTA MIDDA LAGU SOO TALIYEY

→JMC-230230LD. Aagga shaqada 2300mmX2300mm (90.5 inch × 90.5 inch) Awoodda laser: 150W / 300W / 600W / 800W CO2 RF Laser

→JMC-250300LD. Aagga shaqada 2500mm × 3000mm (98.4 inch × 118 inch) Awoodda laser: 150W / 300W / 600W / 800W CO2 RF Laser

→JMC-300300LD. Aagga shaqada 3000mmX3000mm (118 inch × 118 inch) Awoodda laser: 150W / 300W / 600W / 800W CO2 RF Laser ……

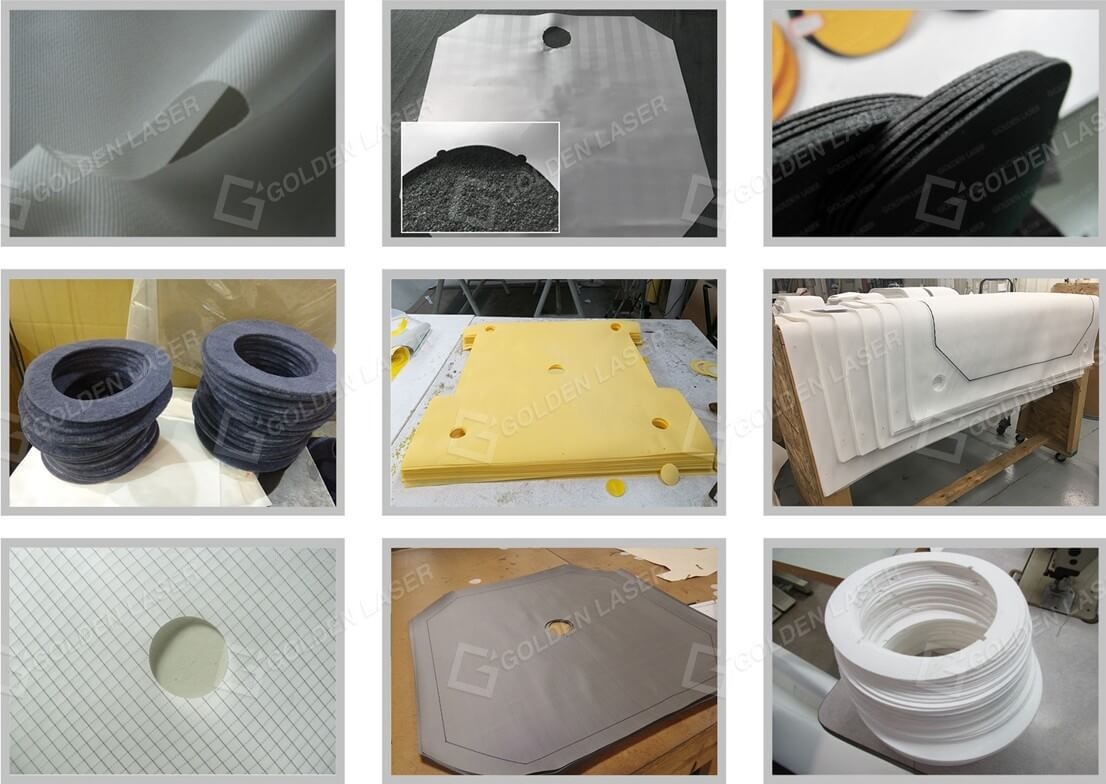

AALADAHA CODSIGA

Dharka sifaynta, maro filter, fiber galaas, dhar aan tolmo lahayn, warqad, xumbo, suuf, polypropylene, polyester, PTFE, polyamide, dhar polymer synthetic, naylon iyo dharka kale ee warshadaha.

Shaandhooyinka Warbaahineed ee Goynta Laser-ka

Hordhaca Warshadaha

Sifeynta sida habka muhiimka ah ee ilaalinta deegaanka iyo badbaadada, laga bilaabo kala-soocidda gaaska adag ee warshadaha, kala-soocidda dareeraha gaaska, kala-soocidda dareeraha adag, kala-soocidda adag ee adag, qalabka maalinlaha ah ee guriga ee nadiifinta hawada iyo nadiifinta biyaha, shaandhaynta ayaa si ballaaran loo dabaqay meelo badan. Codsiyada gaarka ah sida dhirta korontada, biraha birta, dhirta sibidhka iyo qiiqa kale, warshadaha dharka iyo dharka, sifaynta hawada, daaweynta wasakhda, crystallization warshadaha kiimikada, hawada warshadaha baabuurta, filter saliid iyo qaboojinta guriga, vacuum nadiifiyaha iyo wixii la mid ah. Maaddooyinka shaandhada ugu weyni waa walxo fibro ah, dhar tolsan iyo walxo bir ah, gaar ahaan kuwa ugu badan ee loo isticmaalo fiber-ka, gaar ahaan suufka, dhogorta, linenka, xariirta, fiber viscose, polypropylene, naylon, polyester, acrylic, nitrile, sida fiilooyinka synthetic, iyo sidoo kale fiilooyinka galaaska, fiilooyinka dhoobada, fiilooyinka birta iyo wixii la mid ah. Codsiyada ayaa si joogto ah u balaadhinaya oo walxaha shaandhaynta sidoo kale waa la cusboonaysiiyaa, badeecada ka timaadda marada boodhka, bacaha boodhka, filtarrada fuustooyinka, shaandhaynta suufka, si loo shaandheeyo.

GOOYNTA LAASERKA/GOYNTA MINDIYADDA / ISBARBAR-DHIGGA HORUMARKA FEERKA

| LAASERKA GOOYNTA | Mindida GOOYNTA | Feer | |

| GOYNTA TAYO CIID | DHAQAN | FRAYDAY | FRAYDAY |

| JARAY tayada meertada | SAX AH | QURXOON | QURXOON |

| FAAHFAAHIN FIICAN / DARYEEL GUDAHA OO KA BILAASH AH | HAA | SHURUUD AH | SHURUUD AH |

| XIDHIIDHKA CIIDA JARAY | HAA | NO | NO |

| Dabacsanaan / Shakhsinimo | SARE | SARE | LIMITED |

| SALAAMAYNTA / XIRIIRKA | HAA | NO | NO |

| MARKII LA GOOYNAYO ALAAB | NO (xiriir la'aan darteed) | HAA | HAA |

SOCODKA HAWLAHA LAASERKA

3 TALLAABO | 1 QOF SHAQO

<<Ka akhriso wax badan oo ku saabsan Sifeynta Qalabka Laser-ka Xalalka Goynta