Filtration Fabric Laser Cutting Machine e nang le Automatic Systems

Nomoro ea mohlala: JMCCJG-300300LD

Selelekela:

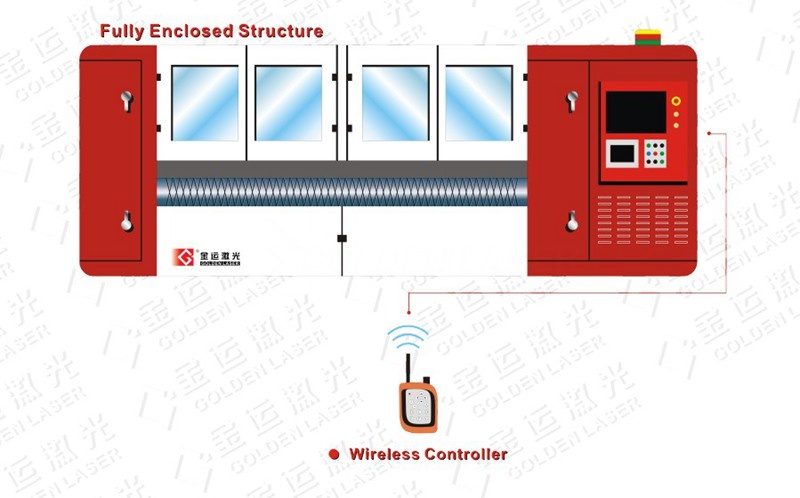

- Sebopeho se koetsoeng ka botlalo.

- Gear le rack driven - lebelo le phahameng le ho nepahala ho phahameng.

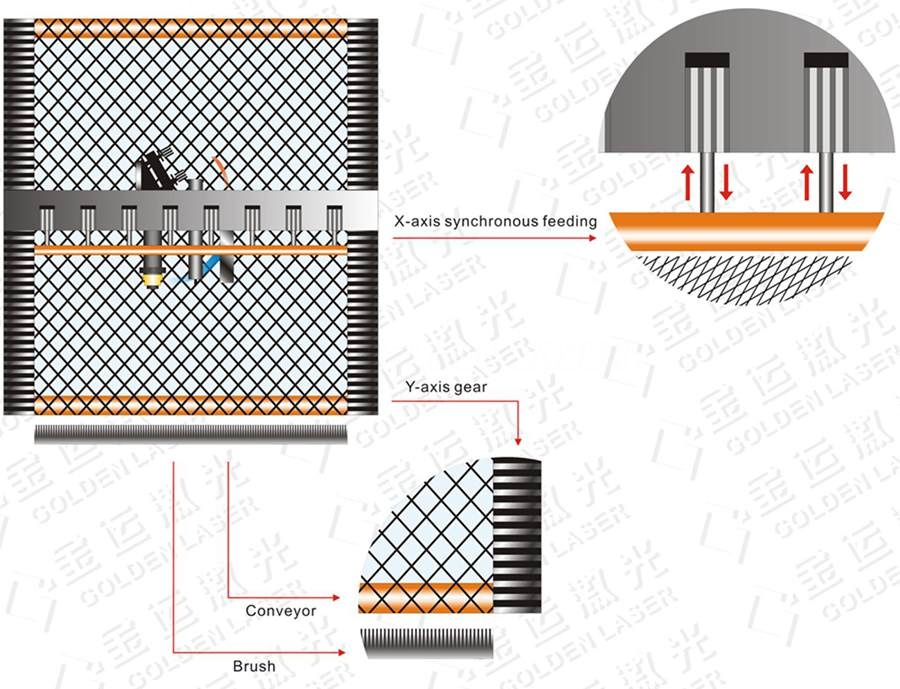

- Mekhoa e ikemetseng e nang le conveyor le auto-feeder.

- Sebaka se seholo sa ho sebetsa sa sebopeho - Boholo ba litafole bo ka tloahelehang.

- Dikgetho: Mojule wa ho tshwaya le mokgwa wa ho hlopha othomathike.

- Mohloli oa laser:CO2 laser

- Matla a Laser:150watt, 300watt, 600watt, 800watt

- Sebaka sa ho sebetsa :3000mm×3000mm (118”×118”)

- Kopo :Sefa lesela la khatiso, limmete tsa sefa, lisebelisoa tsa sefa le li-texiles tsa tekheniki

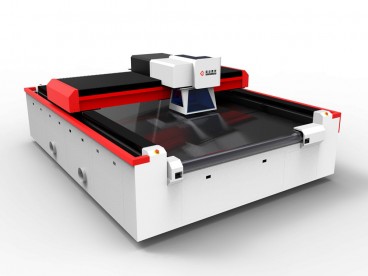

GOLDENLASER JMC SERIES CO2 Laser Cutting Machine

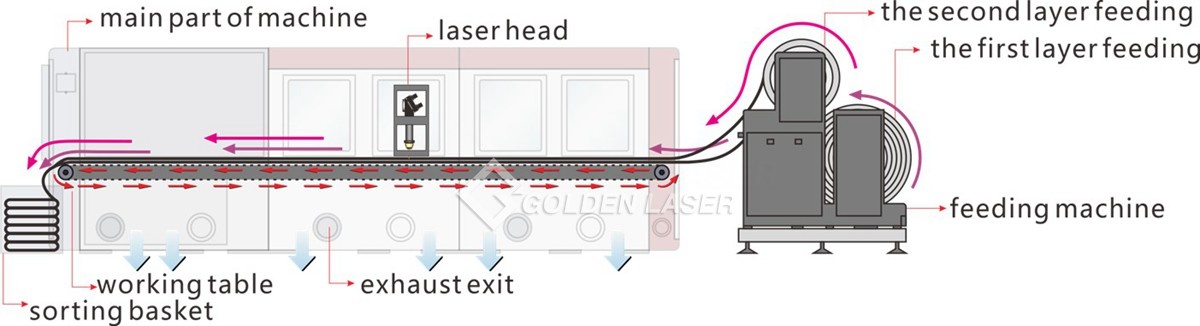

Phallo ea ts'ebetso ea laser othomathike

Tlhahiso ea rona ea maemo a holimo ea mochine oa ho itšeha oa CO2 laser, katoloso ea mesebetsi e mengata, ho hlophisoa ha mekhoa ea ho fepa le ho hlophisa ka mokhoa o itekanetseng, lipatlisiso le nts'etsopele ea software e sebetsang ... Tsohle e le ho fana ka bareki ka katleho e phahameng ea tlhahiso, ts'ebetso e ntlafalitsoeng ea tlhahiso, ho boloka litšenyehelo tsa moruo le litšenyehelo tsa nako, le ho eketsa melemo.

Bohlokoa ba JMC Series Cutting Laser Machine

1. Sebopeho se koetsoeng ka botlalo

Large format laser cutting bed e nang le sebopeho se koaletsoeng ka ho feletseng ho etsa bonnete ba hore lerōle la ho itšeha ha le tsoe, le loketse ho sebetsa setsing sa tlhahiso e matla.

Ho feta moo, sesebelisoa sa mohala se sebelisoang ke mosebedisi se ka lemoha ts'ebetso e hole.

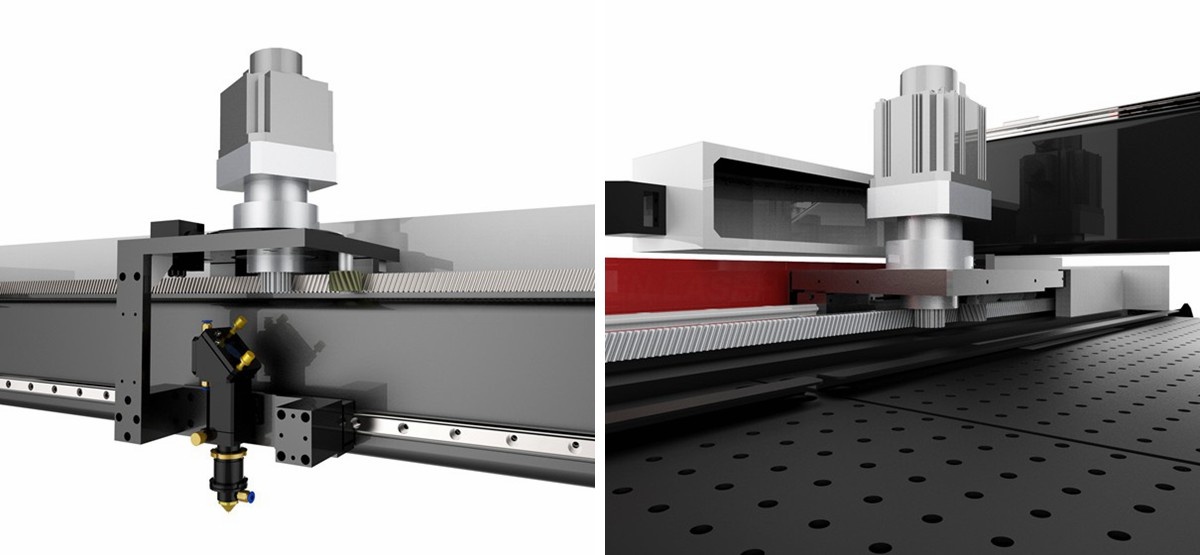

2. Gear & Rack e tsamaisoa

Ho nepahala ho phahamengHo khanna Gear & Racktsamaiso. Ho itšeha ka lebelo le phahameng. Ho potlakisa ho fihla ho 1200mm/s, ho potlakisa 10000mm/s2, 'me e ka boloka botsitso ba nako e telele.

- Boemo bo phahameng ba ho nepahala le ho pheta-pheta.

- Netefatsa boleng bo botle ba ho itšeha.

- E tšoarellang le e matla. Bakeng sa tlhahiso ea hau ea 24/7h.

- Bophelo ba tšebeletso bo feta lilemo tse 10.

3. Phepelo e nepahetseng ea tsitsipano

Litlhaloso tsa Auto-feeder:

- Bophara ba rolara e le 'ngoe ho tloha ho 1.6 metres ~ 8 metres; bophara bo boholo ba moqolo ke mithara e le 1; Boima ba theko e tlase ho fihla ho 500 KG

- Ho fepa ka boiketsetso ka ho inductor ka masela; Tokiso ea ho kheloha ka ho le letona le le letšehali; Boemo ba lintho tse bonahalang ka ho laola ka bohale

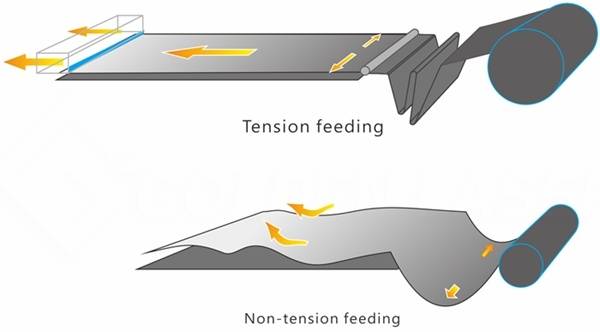

Phepelo e nepahetseng ea tsitsipano

Ha ho na "tension feeder" ho ka bang bonolo ho khopamisa phapano ts'ebetsong ea ho fepa, e leng se tla fella ka keketseho e tloaelehileng ea tokiso;

Tension feederka akaretsang e tsitsitseng ka mahlakoreng a mabeli a thepa ka nako e tšoanang, le ka tsela e iketsang hula lesela pelehi ka rolara, tshebetso tsohle le tsitsipano, e tla ba khalemelo e phethahetseng le ho fepa ka nepo.

Ho fepa ka tsela e lumellanang ea X-axis

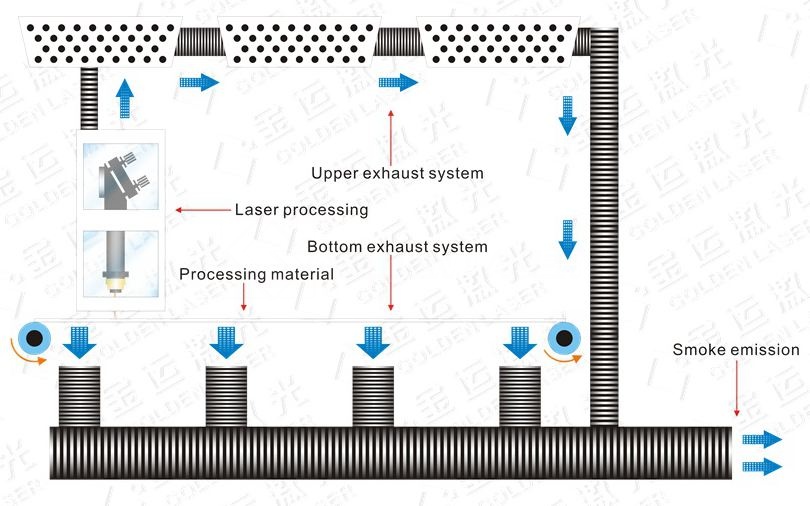

4. Diyuniti tsa exhaust le filter

Melemo

• Kamehla finyella boholo ba ho itšeha boleng

• Lisebelisoa tse fapaneng li sebetsa litafoleng tse fapaneng tsa ts'ebetso

• Taolo ea boikemelo ea ho ntša holimo kapa tlase

• Khatello ea ho hula ho pholletsa le tafole

• Etsa bonnete ba hore moea o na le moea o motle ka ho fetisisa tikolohong ea tlhahiso

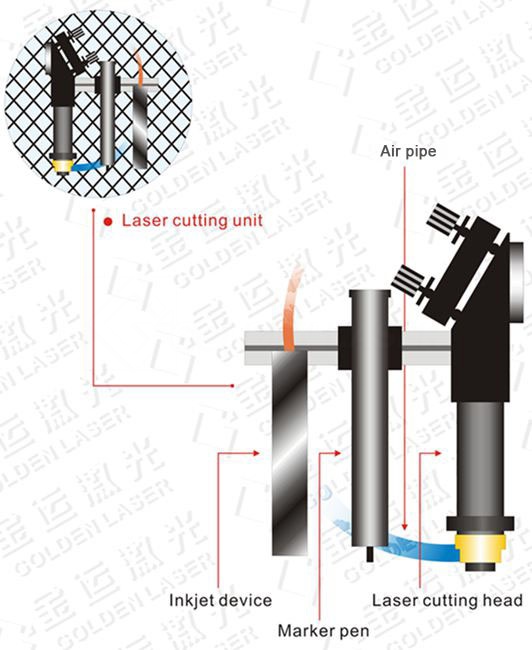

5. Mekhoa ea ho tšoaea

Ho ea ka litlhoko tsa bareki, mochine oa khatiso oa enke-jet le mochine oa pene oa letšoao o ka kenngoa hloohong ea laser ho tšoaea thepa ea filthara, e loketseng ho roka hamorao.

Mesebetsi ea khatiso ea enke-jet:

1. Tšoaea lipalo 'me u sehe moeli ka nepo

2. Nomoro off-cut

Basebelisi ba ka tšoaea ho off-cut ka lintlha tse ling joalo ka saese e khaotsoeng le lebitso la thomo

3. Ho tšoaea ntle le mabitso

Ho tšoaea ntle le mabitso ke khetho e ntle ka ho fetisisa ea ho roka. Litsela tse nepahetseng tsa sebaka li etsa hore mosebetsi o latelang o sebetse habonolo.

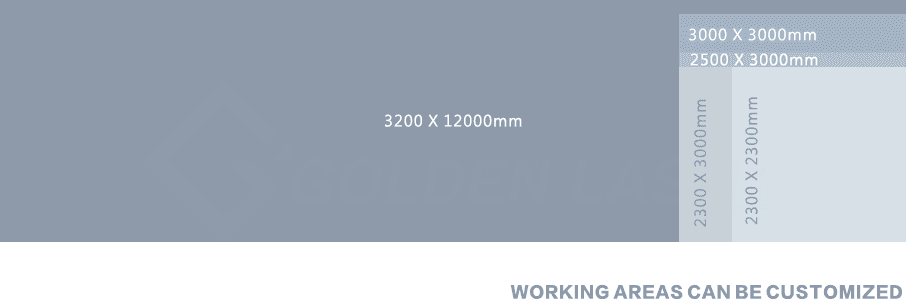

6. Libaka tsa ho itšeha tseo u ka li khethang

2300mm×2300mm (90.5in×90.5in), 2500mm×3000mm (98.4in×118in), 3000mm×3000mm (118in×118in), 3500mm×4000mm (137.7in×157in) Kapa likhetho tse ling. Sebaka se seholo sa ho sebetsa se fihla ho 3200mm×12000mm (126in×472.4in)

Shebella Mochini oa ho Seha Laser bakeng sa Sefa Tobetsa Lesela ka Ketso!

Tekheniki Parameter

| Mofuta oa laser | CO2 RF laser tube |

| Matla a laser | 150W / 300W / 600W / 800W |

| Sebaka sa ho Seha | 3000mm×3000mm (118”×118”) |

| Tafole ea ho sebetsa | Tafole ea ho sebetsa ea vacuum conveyor |

| Sistimi ea motsamao | Gear le rack e khannoang, Servo motor |

| Ho poma lebelo | 0-1200mm/s |

| Ho potlakisa | 8000mm/s2 |

| Sistimi ea ho tlotsa | Automatic lubrication system |

| Sistimi ea ho ntša mosi | Pipe e khethehileng ea ho hokahanya e nang le li-blower tsa N centrifugal |

| Sistimi ea ho pholisa | Sistimi ea "processional" ea mantlha ea chiller ea metsi |

| Hlooho ea laser | Processional CO2 laser ho itšeha hlooho |

| Taolo | Sistimi ea taolo ea kantle ho marang-rang |

| Pheta ho nepahala ha maemo | ± 0.03 limilimithara |

| Ho beha ho nepahala | ± 0.05 limilimithara |

| Min. kerf | 0.5 ~ 0.05mm (ho itšetlehile ka thepa) |

| Kakaretso ea matla | ≤25KW |

| Sebopeho se tšehelitsoe | PLT, DXF, AI, DST, BMP |

| Phepelo ea motlakase | AC380V±5% 50/60Hz 3Phase |

| Setifikeiti | ROHS, CE, FDA |

| Dikgetho | Auto-feed, Maemo a matheba a mafubelu, Sisteme ea ho tšoaea, Sistimi ea Galvo, Lihlooho tse peli, kh'amera ea CCD |

※ Libaka tsa ts'ebetso li ka etsoa ka kopo.

Likarolo tse ka Sehloohong le Likarolo

| Lebitso la Sehlooho | Qty | Tšimoloho |

| Laser tube | 1 sete | Rofin (Jeremane) / Coherent (USA) / Synrad (USA) |

| Lense ea maikutlo | 1 pc | II IV USA |

| Servo motor le mokhanni | 4 lihlopha | YASKAWA (Japane) |

| Rack le pinion | 1 sete | Atlanta |

| Hlooho ea laser e tsepamisitsoeng maikutlo | 1 sete | Li-raytools |

| Se fokotsang lisebelisoa | 3 lihlopha | Alpha |

| Tsamaiso ea taolo | 1 sete | GoldenLaser |

| Tataiso ea liner | 1 sete | Rexroth |

| Automatic lubricating system | 1 sete | GoldenLaser |

| Sehatsetsi sa metsi | 1 sete | GoldenLaser |

JMC SERIES LASER SEHA MACHINE KHOTHATSOANG MEFUTA

→JMC-230230LD. Sebaka sa Mosebetsi 2300mmX2300mm (90.5 inch×90.5 inch) Matla a Laser: 150W / 300W / 600W / 800W CO2 RF Laser

→JMC-250300LD. Sebaka sa Mosebetsi 2500mm×3000mm (98.4 inch×118 inch) Matla a Laser: 150W / 300W / 600W / 800W CO2 RF Laser

→JMC-300300LD. Sebaka sa Mosebetsi 3000mmX3000mm (118 inch×118 inch) Matla a Laser: 150W / 300W / 600W / 800W CO2 RF Laser … …

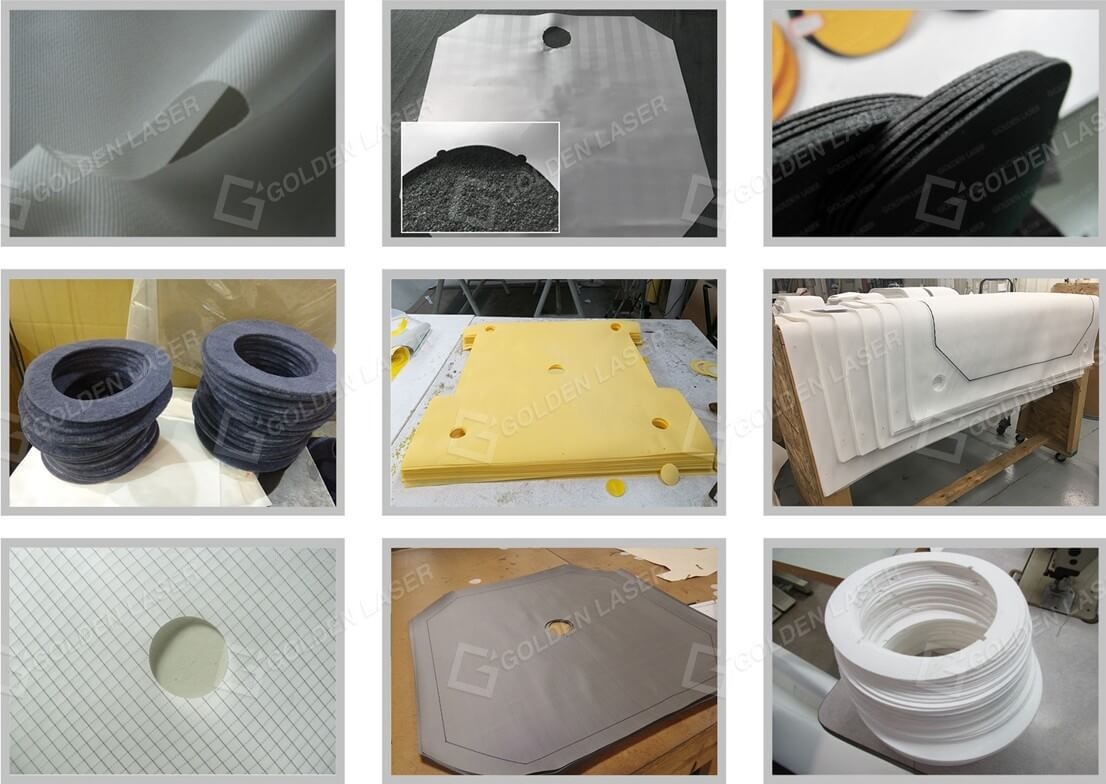

SEBELISA LITŠOANTŠISO

Masela a sefang, lesela le sefang, fiber ea khalase, lesela le sa lohiloeng, pampiri, foam, k'hothone, polypropylene, polyester, PTFE, masela a polyamide, masela a maiketsetso a polymer, nylon le masela a mang a indasteri.

Laser Cutting Filter Mehlala ea Media

Kenyelletso ea indasteri

Filtration e le ts'ebetso ea bohlokoa ea ho laola tikoloho le ts'ireletso, ho tloha karohano e tiileng ea khase ea indasteri, karohano ea mokelikeli oa khase, karohano ea metsi a tiileng, karohano e tiileng-e tiileng, ho ea ho lisebelisoa tsa letsatsi le letsatsi tsa ntlo ho hloekisa moea le ho hloekisa metsi, ho hloekisa ho 'nile ha sebelisoa ka ho eketsehileng libakeng tse ngata. Lisebelisoa tse khethehileng tse kang limela tsa motlakase, limilone tsa tšepe, limela tsa samente le likhase tse ling, indasteri ea masela le liaparo, ho hloekisa moea, ho hloekisa likhoerekhoere, lik'hemik'hale tsa indasteri ea lik'hemik'hale, moea oa indasteri ea likoloi, filthara ea oli le moea oa lapeng, vacuum cleaner joalo-joalo. Lisebelisoa tse ka sehloohong tsa filthara ke lisebelisoa tsa fiber, masela a lohiloeng le lisebelisoa tsa tšepe, haholo lisebelisoa tsa fiber tse sebelisoang haholo, haholo k'hothone, boea, line, silika, viscose fiber, polypropylene, nylon, polyester, acrylic, nitrile, joalo ka likhoele tsa maiketsetso, hammoho le likhoele tsa khalase, likhoele tsa ceramic, likhoele tsa tšepe joalo-joalo. Likopo li lula li atoloha le lisebelisoa tsa ho sefa le tsona lia ntlafatsoa, sehlahisoa se tsoang lesela la lerole, mekotla ea lerōle, libarele tsa filthara, k'hothone ea filthara, ho sefa.

LASER CUTING / THIPA THIPA / Punch PROCESSING PApiso

| LASER KHOOA | KHOOA THIPA | KHOTHA | |

| TS'OANELO KHABANE | TSIETSO | TS'EBELANG | TS'EBELANG |

| KHAOA BOTHO MOHOLO | TLHOKOMELO | TS'OANELO | TS'OANELO |

| LITLHAKISO TSE KHABANE / RADIUS-MAHALA A KA HARE CONTOURS | EE | TS'ELISO | TS'ELISO |

| TIISO E KHABANE | EE | NO | NO |

| FETOHA / BONAHALA | PHAHAMENG | PHAHAMENG | MOEKETSI |

| LABELING / ENGRAVING | EE | NO | NO |

| KHOTHATSO NTHO E KHOA | NO (Ka lebaka la ho se kopane) | EE | EE |

LASER TS'EBETSO PHAPALA

MEHATO E 3 | MOTHO OA 1 MOTHO

<<Bala haholoanyane ka Filter Materials Laser Cutting Solutions